It is not possible to extrude and spheronize everything. Extrusion and spheronization can be used on a wide range of products and formulations. However, if you are having trouble extruding your formulations with the Caleva Multi Lab (CML) then please read this article.

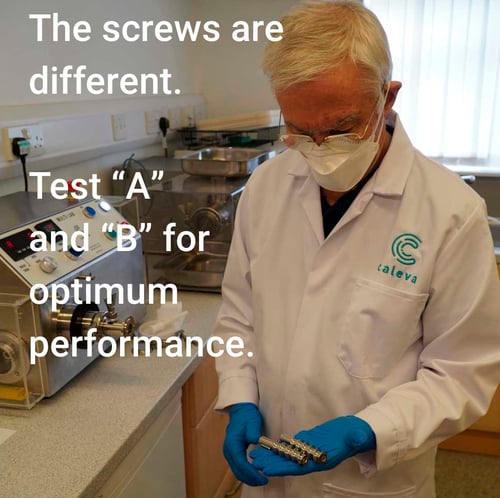

Caleva offers extruder screws of different designs for use with the CML. If you are having issues with the CML then the first thing to do is check you are using the correct screw in your trials. If you did not know that different screw designs were available and please read on below.

- If you purchased a CML earlier than August 2019 then you will just have received “Screw A”

- If you purchased your CML between August 2019 and February 2020 then you may have received either “Screw A” alone or both “Screw A and “Screw B”

- If you purchased your CML after February 2020 then you will have been supplied with both “Screw A” and “Screw B”.

- If you are unsure when the machine was purchased, please contact us with either the machine serial number (found on the power socket plate on the right side of the machine) or your purchase order number (contact your purchasing department). We will help you.

If you have only one extruder screw and you are having problems with the extrusion, then contact us for advice and we will try and help.

Why do Caleva now include two different screw designs as standard?

When the CML was first released the original extrusion screw (Screw A) was a robust and standard design that worked well with the wide range of products that we tested.

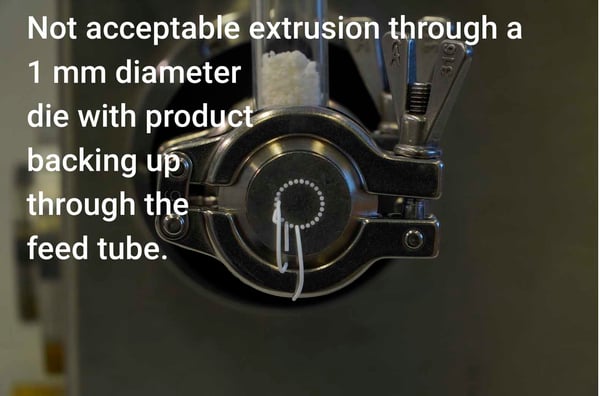

For some time, we had no reports from our customers having difficulties or issues when using the equipment that we have provided. However, we did receive one report from the customer who was having problems extruding his “standard” product. This problem was examined by Caleva. After some testing, trial work and redesign we were able to offer a new extruder screw for the CML (Screw B) that worked well with the customers “standard” formulation. The differences in design between Screw A and Screw B were very minor and almost not distinguishable without a close examination.

It was not possible for us to simply exchange the screw design and continue to provide a modified single screw as trials completed demonstrated several key points.

- Screw A worked well with a wide range of formulations but not with all formulations.

- Screw B also worked well with a range of different formulations but would not extrude some of the products extruded by Screw A.

- Whilst Screw A would not extrude the customer “standard” formulation Screw B extruded his formulation and several similar ones without problems.

General Conclusion

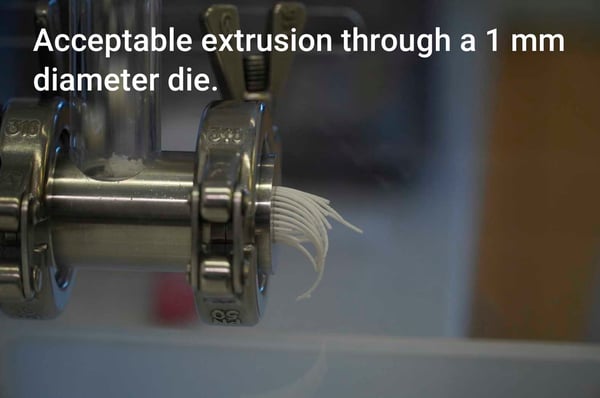

We were not able to offer a screw that would work with as wide a variety of formulations as our customers wished. The idea arose that the provision of two screws with the Caleva CML would offer users the ability to effectively work with a wider range of formulations than a single screw, as offered by most other manufacturers, would be able to do. Using this opportunity provided by the Caleva CML users would be able to work with a wider range of different formulations. This would increase the chances reaching a good solution within a product development program.

Providing two different extrusion screws has some important consequences

- It allows our customer to easily expand the range of products that they can use in development programs.

- It provides scientists and researchers with two screws that enable them to work with a wider range of formulations, increasing their chances of success in their individual formulation development programs.

- The Caleva Multi lab is now supplied (as standard) with two different but similar extruder screws to allow the expansion of formulations that can effectively be extruded.

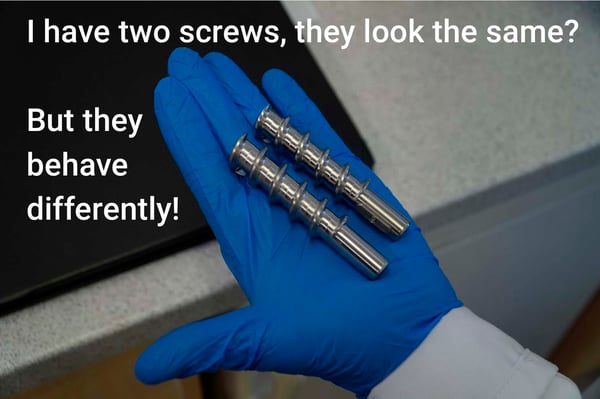

- The two screws are similar in design and without a closer look they are difficult to distinguish apart. However, the effectiveness of these individual screws with different formulations is markedly different.

Recent update

In some laboratories where we have supplied two screws of different designs this fact has been overlooked. On a few occasions we have found users who have struggled with the extrusion of some formulations and have been unaware that a second screw was available that might work more effectively with the formulation being used.

Remember: the different screws are difficult to distinguish with only a cursory glance. If you have extrusion problems then the first question you should ask is "am I using the extruder screw that is appropriate for my formulation".

If you think that this might be a possible contributing factor to your difficulties, then please check if you should have one or two different screws with your machine. The screws are labelled Screw A and/or Screw B. If you have both screws, re-run your trials using both screws.

For additional advice and help or to obtain a second screw with a different design, or to ask which screw you have been supplied with initially, and what your options are now then please contact us at info@caleva.com

If this does not work and your issue is not coming from an incompatibility between the extruder screw and your formulation, then please contact us and ask for additional advice.

Leave A Comment