The rapid integration of artificial intelligence (AI) and machine learning (ML) into pharmaceutical research and manufacturing is reshaping how formulations are designed, tested, and optimized.

Knowledge Base

Titanium Dioxide Ban: Impact, Coating Challenges & Reformulation Solutions

The recent European ban of titanium dioxide in Food and Nutraceutical products creates a huge challenge for the industry and raises wider concerns over its potential extension to the pharmaceutical sector. With thousands of pharmaceutical products currently using titanium dioxide in tablet or capsule coatings, the reformulation race is on to identify suitable alternatives.

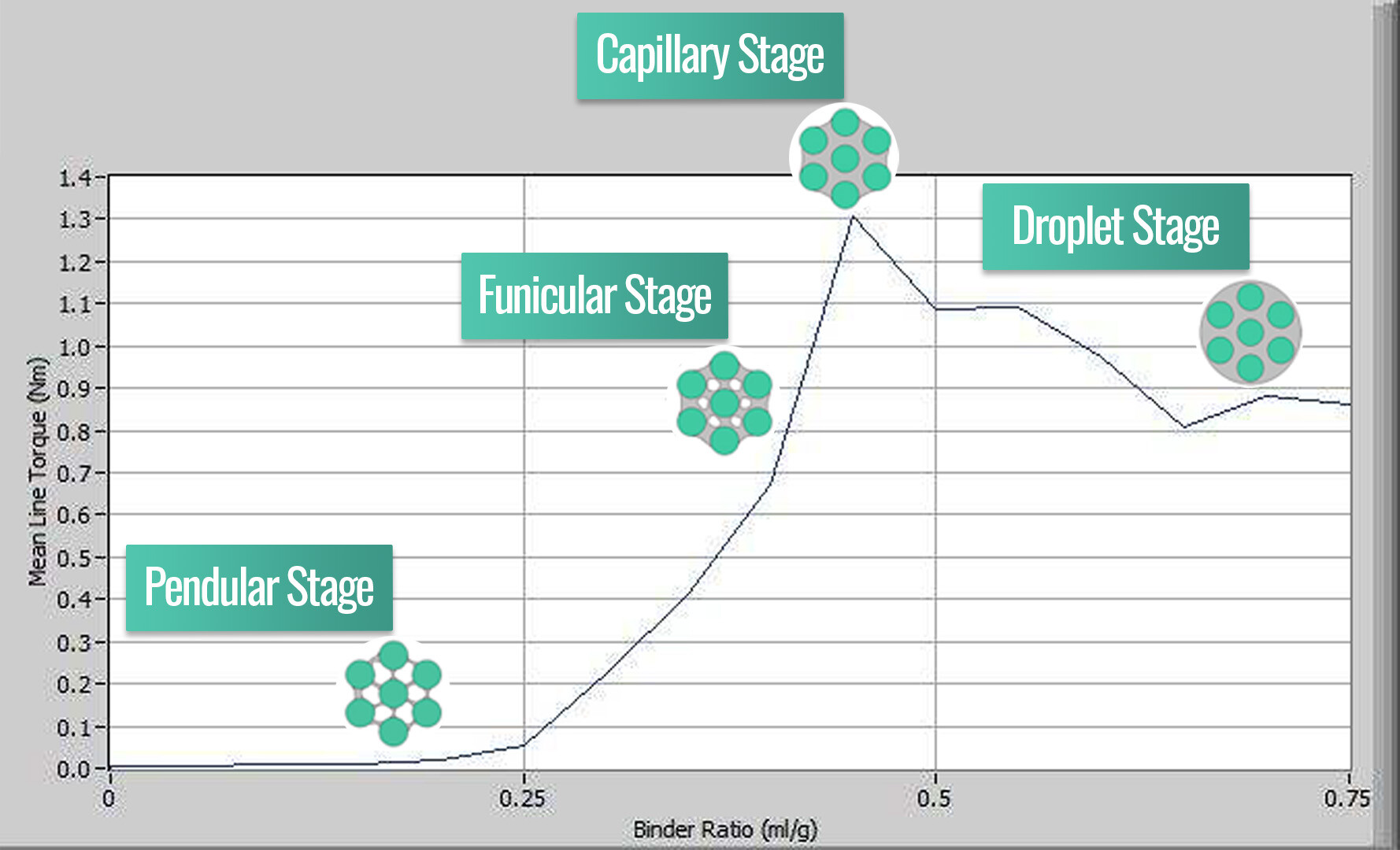

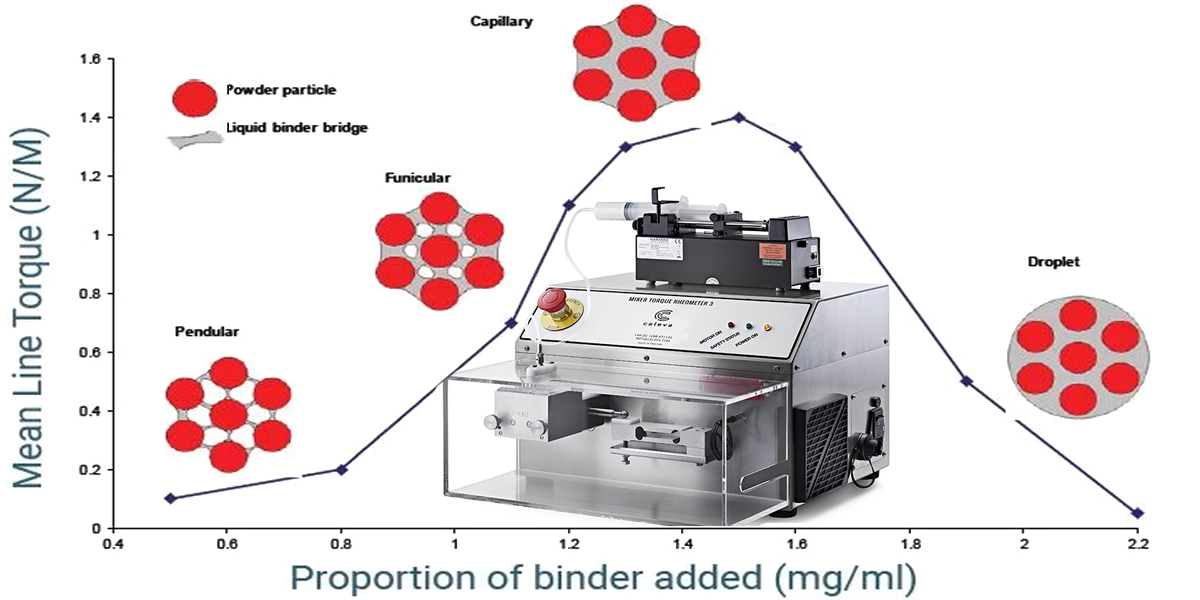

The Importance of Understanding the Rheology of Wet Mass in Tablet Formulation & Manufacture

In the world of pharmaceutical manufacturing, achieving consistently high-quality tablets is a top priority.

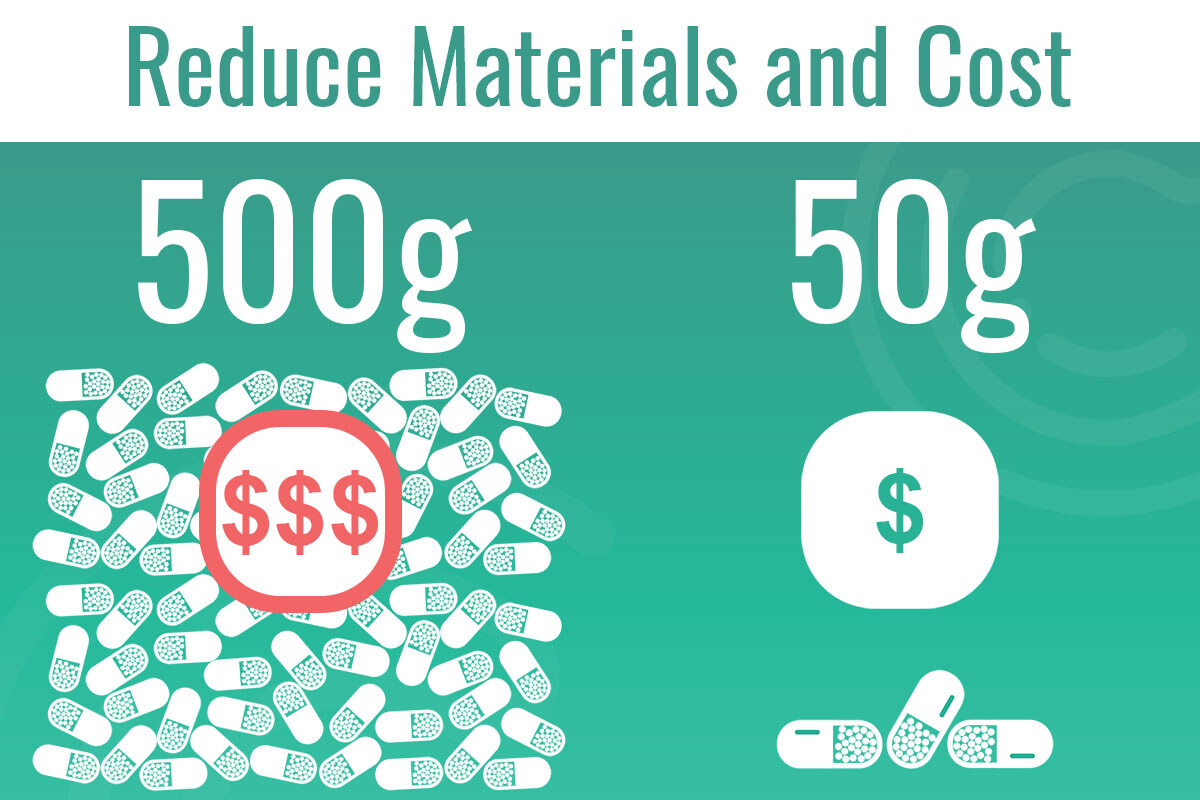

Small is Beautiful: Miniaturisation in Pharmaceutics

The goal of accelerating discovery, development, and delivery of new products in the Pharmaceutical and allied industries is continual. In recent times significant effort has been made to reduce the scale at which research and development (R&D) is possible.

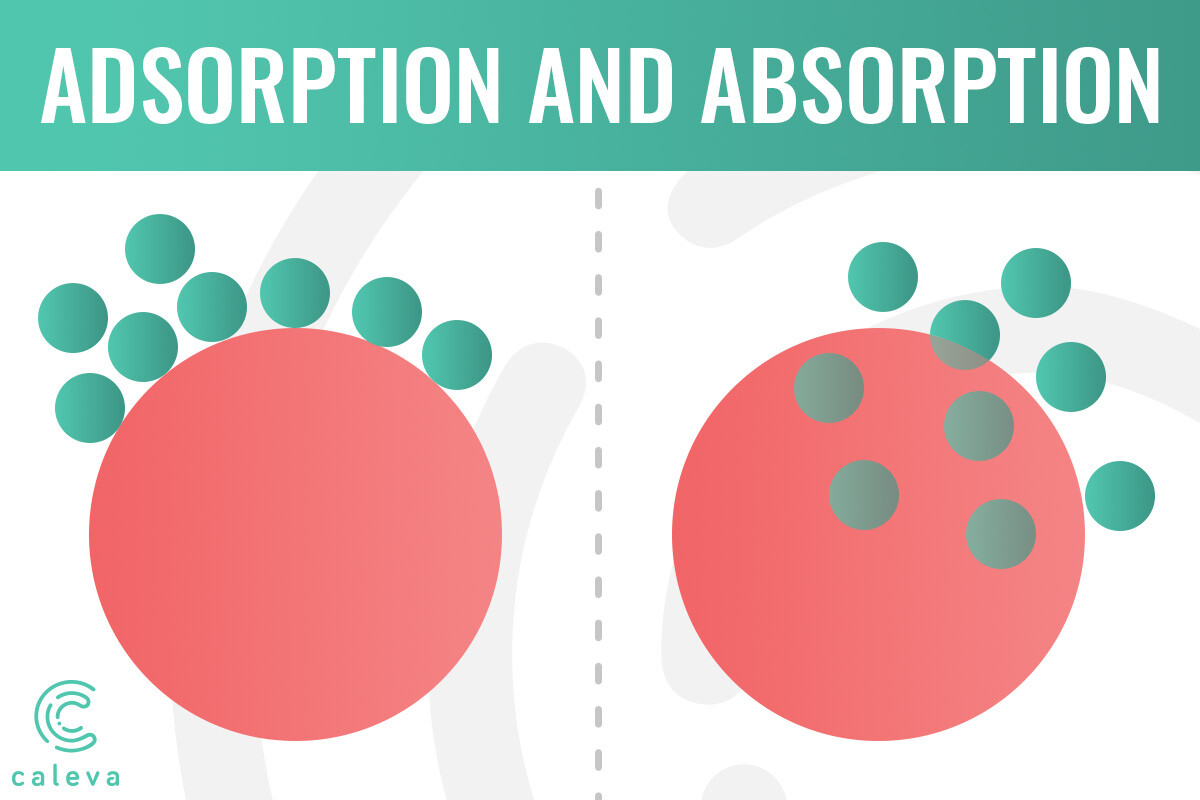

The Unsung Heroes: Adsorption & Absorption in Extrusion-Spheronization

Extrusion-spheronization is a cornerstone technique in pharmaceutical manufacturing, transforming drug substances and excipients into uniform, spherical granules (sometimes called pellets, spheroids or beads).

Overcoming Consistency Challenges in the Iron Making Sector

Caleva's International Sales Manager Steve Mate visited the Department of Chemical Engineering at Osaka Metropolitan University to find out how the Mixer Torque Rheometer (MTR) is being used.

Exciting Development for the Future of Oral Dose Drug Delivery

Investigating drug dissolution enhancement and controlled release of solid-liquid hybrid dosage form using Liqui-Pellet technology.

Discover how the Caleva Multi Lab was used to demonstrate the flexibility and potential of Liqui-Pellets as the next generation oral dosage form.

Caring for Your Lab Machines: The Importance of Regular Machine Maintenance

To meet GCLP requirements in research and development it is essential that your lab machines are functioning at the required standard, providing accurate, reliable, and repeatable results.

5 Reasons Why You Should Choose Caleva

At Caleva we want to help pioneering research and formulation scientists achieve results and we believe that our range of R&D machines should make achieving these results as easy as possible.

Investigating the Impact of Process Variables in Formulation Development

Discover how Caleva extrusion and spheronization equipment supported a university master’s student in his scientific breakthrough, resulting in his publication in a recognised industry journal.

How to Reduce Your Formulation Development Time

Discover how to cut your formulation development time in half with the Caleva Multi Lab and its wide range of variable density dies.

Do I Need a Screen Extruder or a Screw Extruder?

At Caleva, we offer a variety of extruders to meet your needs, from laboratory scale extruders for research and development purposes, to pilot scale extruders and larger models for batch production environments.

Measuring and monitoring your formulation

Did you know that the Mixer Torque Rheometer (MTR) is designed to carry out 3 separate experiments essential to your formulation development and production?

Equipment for the manufacture of pellets

Switch quickly between different materials with this easy to clean CE marked, top quality extrusion and spheronization system. An example of reliable and efficient British engineering at its best - this is the best option for your pellet production and is backed by the highly acclaimed support from Caleva Process Solutions.The Caleva system gives you the ability to vary the density of the...

Formulation development with Caleva

The process of spheronization consists of four key steps:-

- To optimize and achieve the right binder addition & mixing time for your formulation

- Mixing or granulation - a mixer or granulator is required

- Extrusion - an extruder is required

- Spheronization - a spheronizer is required

- Drying and possibly coating - a coater and drier may be required

This is all made simple by the Caleva suite of R&D...

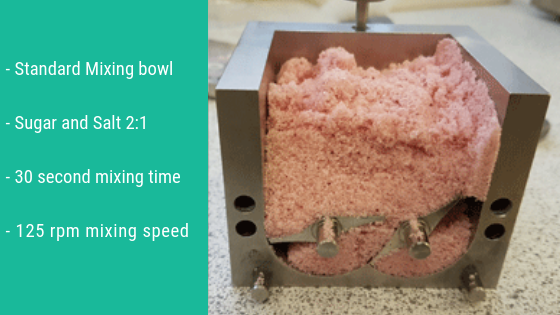

Does the Caleva Mixer/Granulator/Blender allow me to mix and test small batches of product?

We are frequently asked for information about the ability of the smallmixer/granulator/blender, a must have tool for any laboratory needing to complete these processes quickly with small sample sizes. Recent trials provide new information about the capability of the Caleva mixer/granulator/blender (MGB) and its ability to act as a stand alone mixer when mixing powder samples of different sizes...

Book a live online demonstration with Caleva

Are you interested in one of our products and would you like to see it in action?

We provide free R&D system demonstrations live online via video conference wherever you are in the world.

Scott Humphries or Steve Mate will demonstrate and explain advanced equipment features and allow you to see the processes that are relevant to your work. It will be an ideal time to discuss any challenges you...

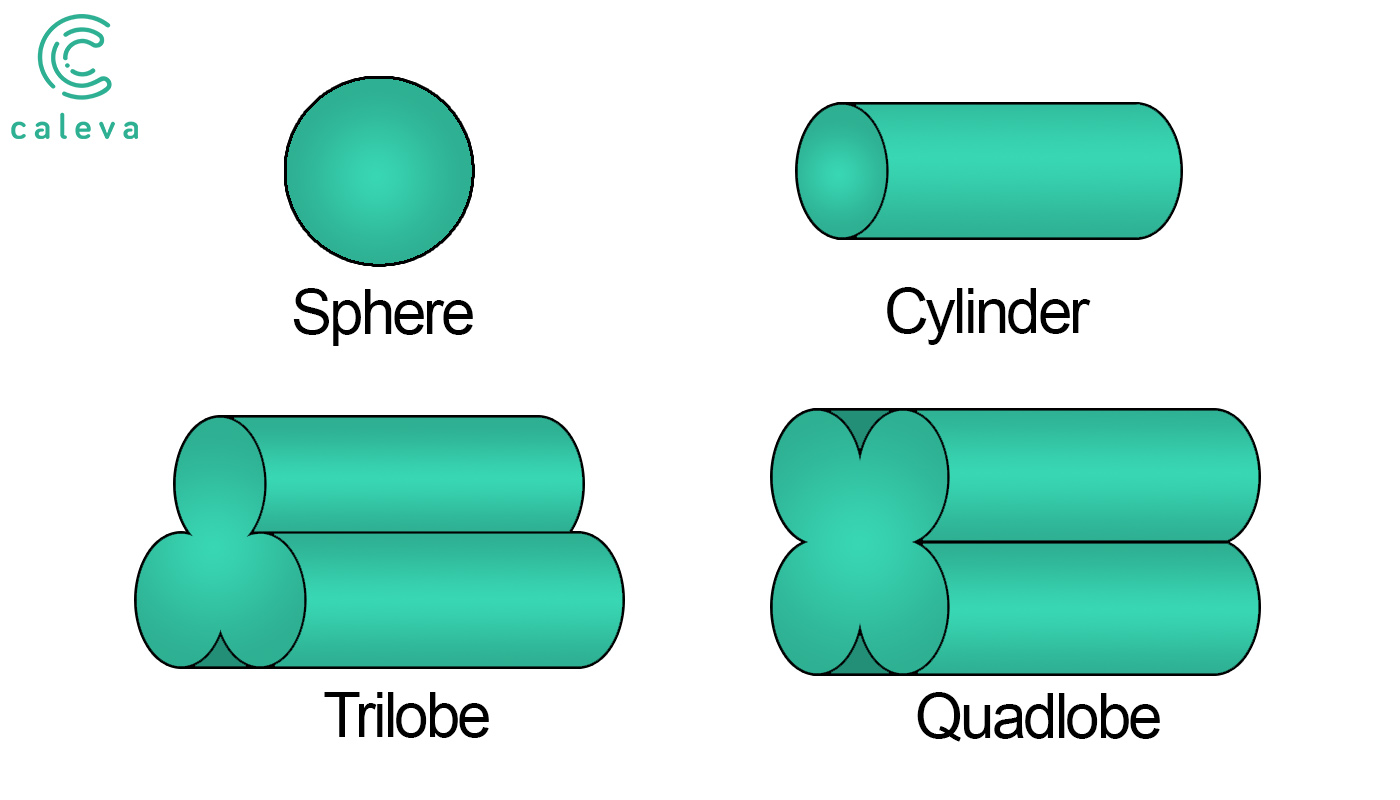

Increase Surface Area of your product with Trilobe and Quadrilobe Dies

An opportunity to shape and form catalyst materials/particles

Caleva have had some considerable success with working with the extrusion of small quantities of catalytic material using the Multi Lab series. (the first steps of blending and mixing can also be completed in the same Multi Lab base machine)

Caleva Study on the Importance of Granulation

Our customer, a major pharmaceutical, biotech & nutraceutical manufacturer with an extensive portfolio of products. For reasons of confidentiality we do not name them.

One of our Production Extruder & Spheronizer Systems for manufacturing on a large-scale was used in trials by the manufacturer, but the pellets produced were not acceptable. As the product was already registered, the composition...

Production Capacity Estimates for Extrusion and Spheronization Systems

We are often asked about the production capacity of our extrusion and spheronization systems. To provide this information there needs to be an understanding of the process parameters that will be used and that have been determined at the development stage. With that information, the advice that we give can be both meaningful and useful in the planning stages.If you have proven your concept at the...