Work with batch sizes from 10g up to 50g (formulation dependent)

"First, we love the multilab machine!!! It is being used every day for multiple projects and we are getting outstanding results and some technology breakthroughs"

Graeme J. Millar | Professor | Science & Engineering Faculty

Queensland University of Technology

Discover what Variable Density Extrusion can do for you

Specialized attachments and design features to increase your chances of development success

Develop your product faster. Prove your concept quickly

A critical process in the creation of a successful formulation

Increase the surface area to volume ratio of your extrudate

3 separate processes on a small, single base unit.

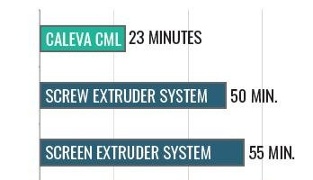

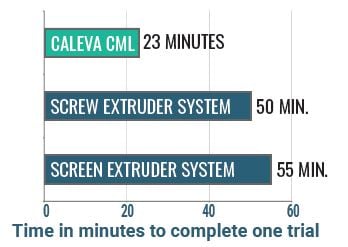

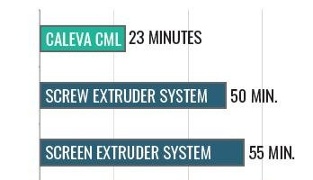

Trials have consistently demonstrated that iterations can be completed in less than half the time required for other standard bench-top systems.

The standard and most efficient process to find the optimum parameters for correct extrusion and spheronization is a trial-and-error approach, conducting multiple experiments where 1 parameter is changed each time. However, with each experiment, the contact parts must be removed, cleaned and then put back onto the machine, wasting valuable time. With the Caleva Multi-Lab, this process is made easy. With quick disassembly and easy to clean components, the CML has an extremely fast turn around speed, allowing you to spend less time cleaning, and more time experimenting.

The Caleva Multi-Lab can fast track your formulation development process, saving you money and lab time.

See the full details of some time trials we performed in our lab.

This important stage of the mixing, extrusion and spheronization process is often overlooked. However, the effect that a poor granulation/mix can have on your pellets may be the difference between a successful development cycle, and an unsuccessful one.

The mixing attachment for the Multi Lab has been designed for small batches of creams, powders, pastes, gels, and powder/liquid combinations in a wide range of proportions.

Mixing/granulation bowls with or without water jackets are available, along with bowls of different sizes.

As an optional extra, the CML also has a high viscosity bowl and blade set that is engineered to work with highly viscous materials that may otherwise be difficult, or even impossible to mix with standard mixing blades.

An automatic timer is built into the CML offering consistent results, through consistent operating parameters.

The Mixer granulator is available as a single separate unit in case you don't need to use the processes of extrusion or spheronization.

Specialist die and bowl/blade sets for catalyst and chemical industries are available with the Multi Lab. In collaboration with some users, we have been successful in mixing and extruding small quantities of catalytic material using the Caleva Multi Lab whilst increasing the surface area/volume ratio of the extrudate produced.

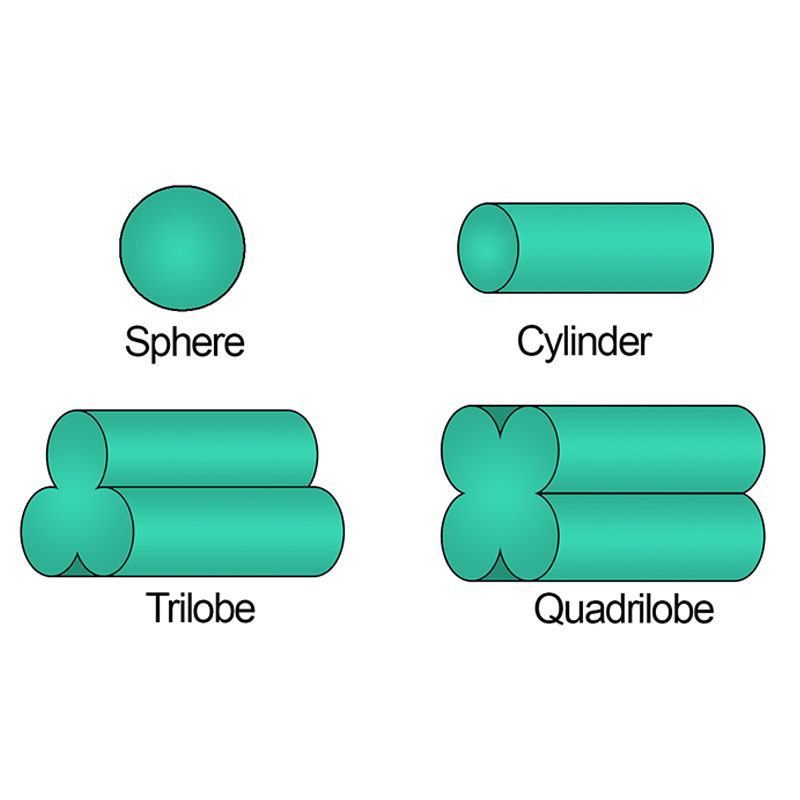

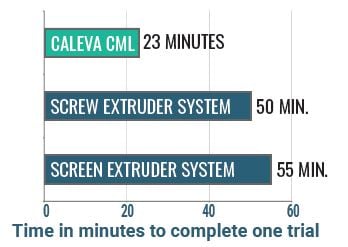

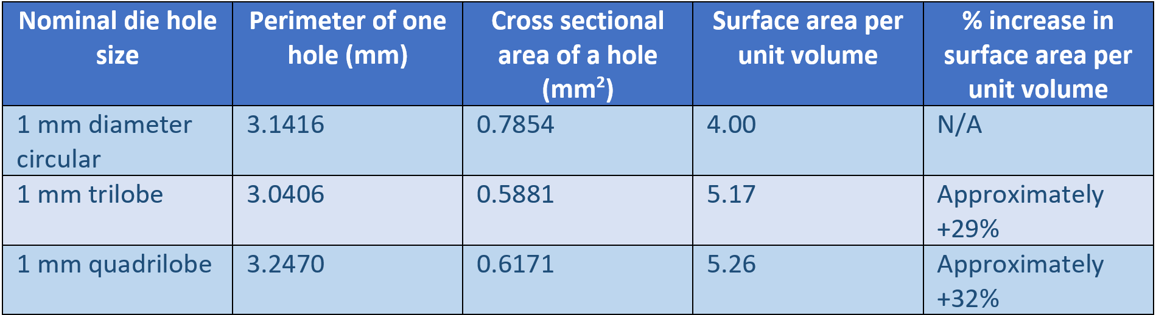

The increased surface extrudate is produced by extruding the active material through a die with trilobe or quadralobe (quadrilobe) holes in place of the traditional round holes. Quadrilobe and trilobe dies in a range of sizes and density configurations that will allow you to increase the surface area to volume ratio of your extrudate.

Bowl and blades sets designed for use with higher viscosity materials are available and recommended with certain materials, contact us for more information.

If you're planning to work with larger quantities of material in the future, we have more equipment that is perfect for scaling up from the Multi lab:

•Caleva Variable Density Extruder (VDE) available for batches from 0.25 to 5 kg.

•Caleva Twin Screw Extruder (VD-TSE) can offer an output of up to 150 kg per hour.

•Variable density dies are available throughout the range of Caleva screw type extruders.

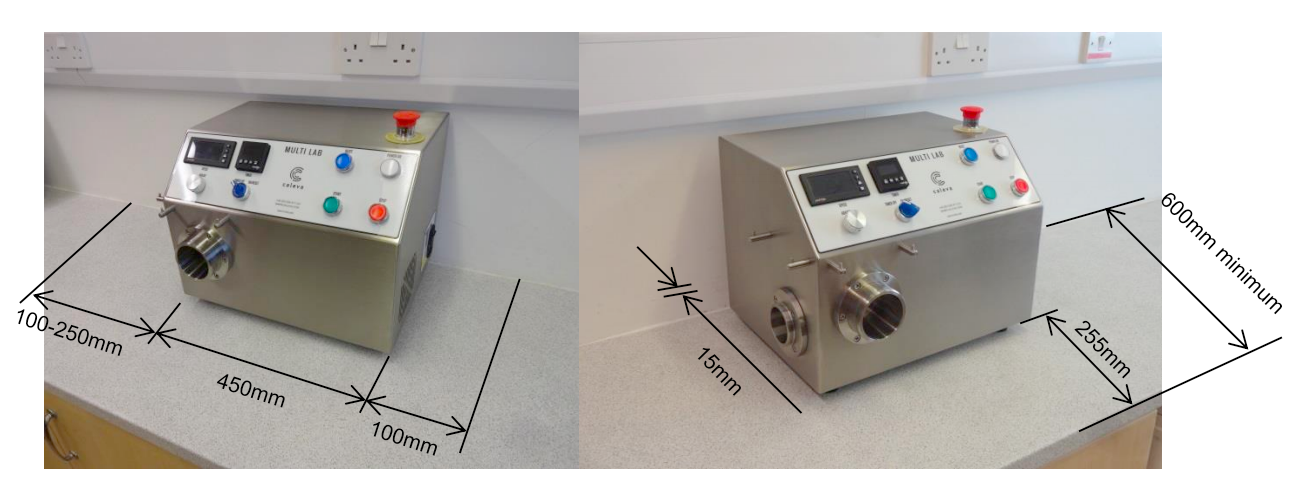

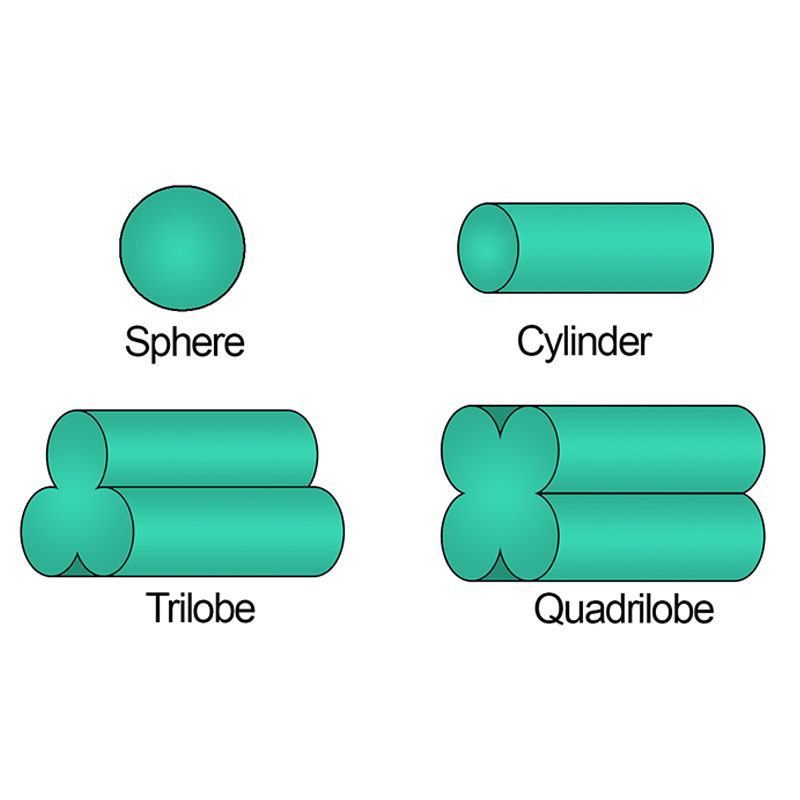

A remarkably small “footprint” for a full size research tool when laboratory bench-top space is at a premium.

The small size of the CML is just one of the many advantages that this piece of equipment can offer. Having the ability to complete 3 processes in one machine, whilst also taking up a minimal amount of bench top space, makes the CML a great addition to any lab space that works with the processes of mixing/granulation, extrusion and spheronization.

The CML can reduce your space requirement by 75% compared to other bench-top equipment offering similar functionality.

Discover what Variable Density Extrusion can do for you

Specialized attachments and design features to increase your chances of development success

Develop your product faster. Prove your concept quickly

Trials have consistently demonstrated that iterations can be completed in less than half the time required for other standard bench-top systems.

The standard and most efficient process to find the optimum parameters for correct extrusion and spheronization is a trial-and-error approach, conducting multiple experiments where 1 parameter is changed each time. However, with each experiment, the contact parts must be removed, cleaned and then put back onto the machine, wasting valuable time. With the Caleva Multi-Lab, this process is made easy. With quick disassembly and easy to clean components, the CML has an extremely fast turn around speed, allowing you to spend less time cleaning, and more time experimenting.

The Caleva Multi-Lab can fast track your formulation development process, saving you money and lab time.

See the full details of some time trials we performed in our lab.

A critical process in the creation of a successful formulation

This important stage of the mixing, extrusion and spheronization process is often overlooked. However, the effect that a poor granulation/mix can have on your pellets may be the difference between a successful development cycle, and an unsuccessful one.

The mixing attachment for the Multi Lab has been designed for small batches of creams, powders, pastes, gels, and powder/liquid combinations in a wide range of proportions.

Mixing/granulation bowls with or without water jackets are available, along with bowls of different sizes.

As an optional extra, the CML also has a high viscosity bowl and blade set that is engineered to work with highly viscous materials that may otherwise be difficult, or even impossible to mix with standard mixing blades.

An automatic timer is built into the CML offering consistent results, through consistent operating parameters.

The Mixer granulator is available as a single separate unit in case you don't need to use the processes of extrusion or spheronization.

Increase the surface area to volume ratio of your extrudate

Specialist die and bowl/blade sets for catalyst and chemical industries are available with the Multi Lab. In collaboration with some users, we have been successful in mixing and extruding small quantities of catalytic material using the Caleva Multi Lab whilst increasing the surface area/volume ratio of the extrudate produced.

The increased surface extrudate is produced by extruding the active material through a die with trilobe or quadralobe (quadrilobe) holes in place of the traditional round holes. Quadrilobe and trilobe dies in a range of sizes and density configurations that will allow you to increase the surface area to volume ratio of your extrudate.

Bowl and blades sets designed for use with higher viscosity materials are available and recommended with certain materials, contact us for more information.

If you're planning to work with larger quantities of material in the future, we have more equipment that is perfect for scaling up from the Multi lab:

•Caleva Variable Density Extruder (VDE) available for batches from 0.25 to 5 kg.

•Caleva Twin Screw Extruder (VD-TSE) can offer an output of up to 150 kg per hour.

•Variable density dies are available throughout the range of Caleva screw type extruders.

3 separate processes on a small, single base unit.

A remarkably small “footprint” for a full size research tool when laboratory bench-top space is at a premium.

The small size of the CML is just one of the many advantages that this piece of equipment can offer. Having the ability to complete 3 processes in one machine, whilst also taking up a minimal amount of bench top space, makes the CML a great addition to any lab space that works with the processes of mixing/granulation, extrusion and spheronization.

The CML can reduce your space requirement by 75% compared to other bench-top equipment offering similar functionality.

The short answer is yes.

We at Caleva have been making pellets and extrudates for over 50 years. If you share with us details of what you are trying to achieve then we would be in a good position to share our experience and guide you to the right equipment for you. This should enable you to be confident that the equipment that you buy is appropriate for your project. This support and advice should be used before purchase decisions are made.

Development and production equipment is normally a significant purchase that should be suitable for what you want to do for several years into the future. It is important that the right decisions are taken before the equipment purchases are decided. For many purchasers, the technology that they are investing into is relatively new and may not be well known. In these cases, the time to obtain advice is before the purchase decisions are made.

Yes, although it depends on your formulation properties.

The CML is designed to work with very small amounts of material (10g - 50g depending on your formulation) to keep the amount of product waste to a minimum.

There are 2 different sized bowls used for mixing on the CML, one full-sized and one half sized.

The smaller bowl has a batch size of about 10 to 20 grams (wet weight) and using smaller blades provides more power to be applied to a smaller mixing surface. Mixing bowls can be used with or without inserts as required.

In the case of very scarce or expensive materials a small bowl will help to run trials with smaller amounts of material. Using 15 grams of material in the smaller mixing bowl will provide a sample that is still large enough to effectively use in the extruder and spheronizer.

Watch a video of the CML mixing small batches of material

If your experimental work might benefit from being either heated or cooled in the CML granulator mixing bowl during the experimental process, an optional water jacketed bowl can be supplied with your CML. The water jacketed bowl is suitable for heating or cooling can be offered with both the full size and the reduced size bowls. A separate water bath and circulation pump will be necessary.

Caleva can also provide a heating and cooling water circulatory system if required.

For working with very “high viscosity“ materials an advanced sigma blade has been designed. This allows a more viscous type of material to be effectively mixed or granulated in the CML system.

The Sigma configuration is designed for use if your material is highly viscous and difficult to work with and where there is a greater focus on mixing than generating a high shear.

The Sigma blades also contra-rotate from each other, however, the blades do not overlap.

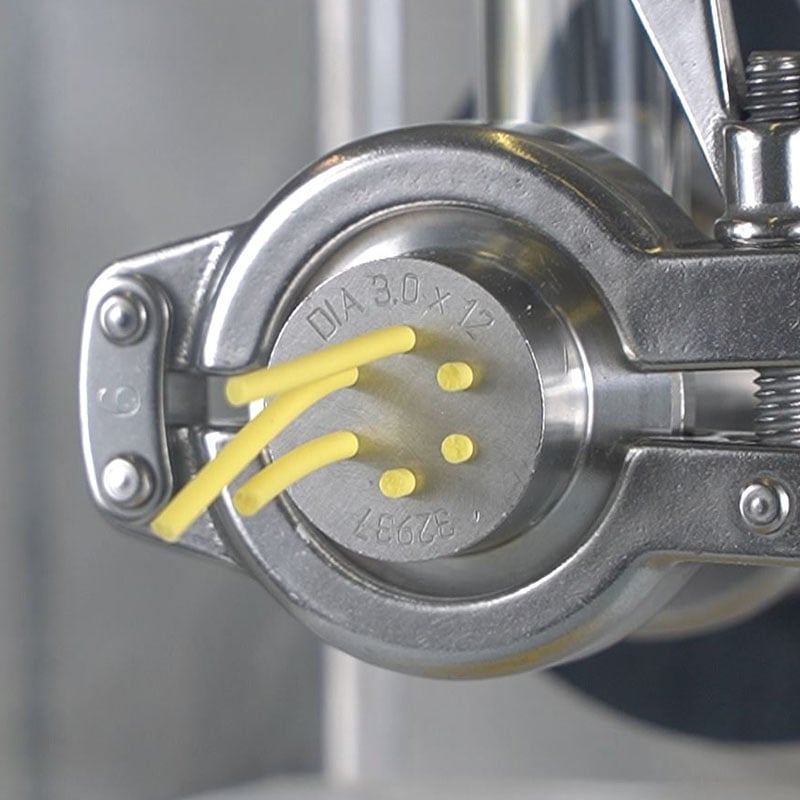

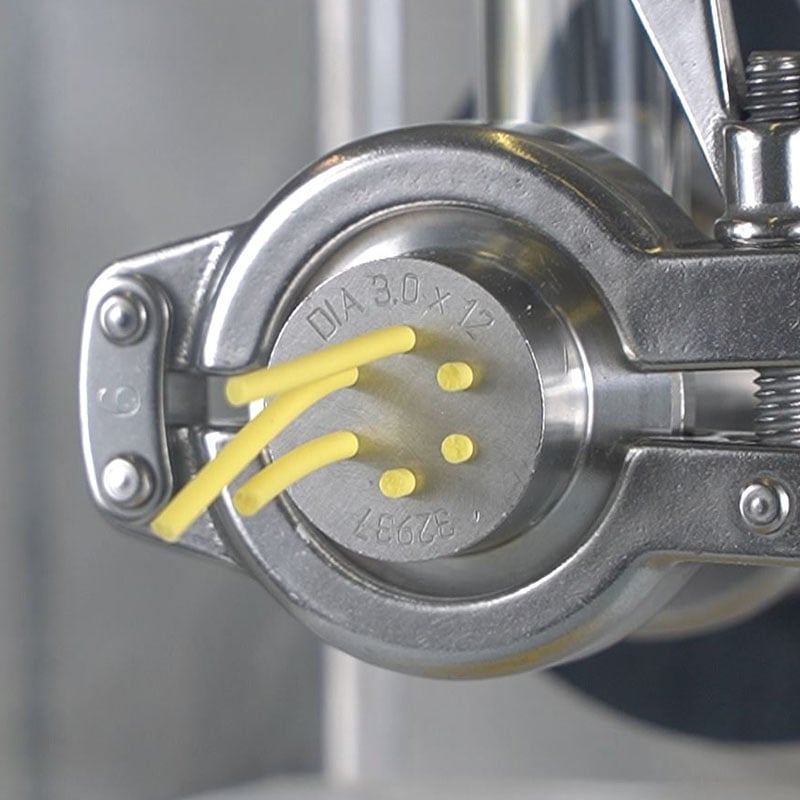

Yes, the CML Extrusion attachment can come with a variety of dies that can be used to control pellet size.

The determination of the pellet size is mostly due to the diameter of the extrusion hole in the extruder die. As a general rule, the pellet will approximately have the same diameter as the die holes. This can vary a little, but this is the factor that has the greatest influence on pellet size.

Caleva can offer CML dies with hole diameters from 0.5 mm to 3.0 mm in 0.1 mm increments.

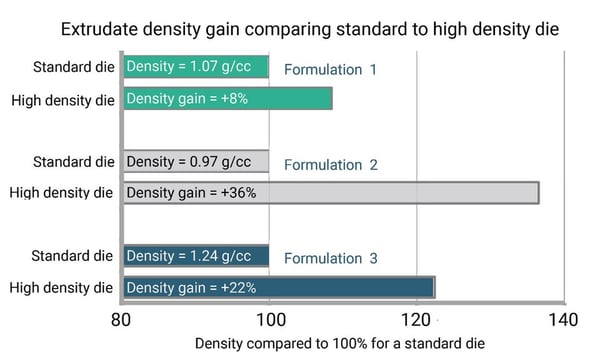

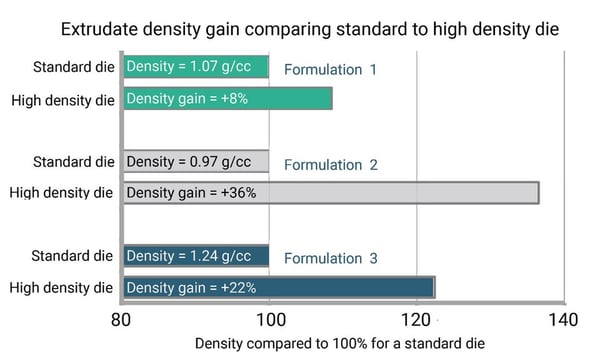

We offer dies that produce extrudate of different density. The effectiveness of these dies is dependent on the properties of your specific formulation. The basic equipment is supplied with one “standard” and one “high density” die. This way you can explore the benefits of variable density, without extra cost. (More die options are available)

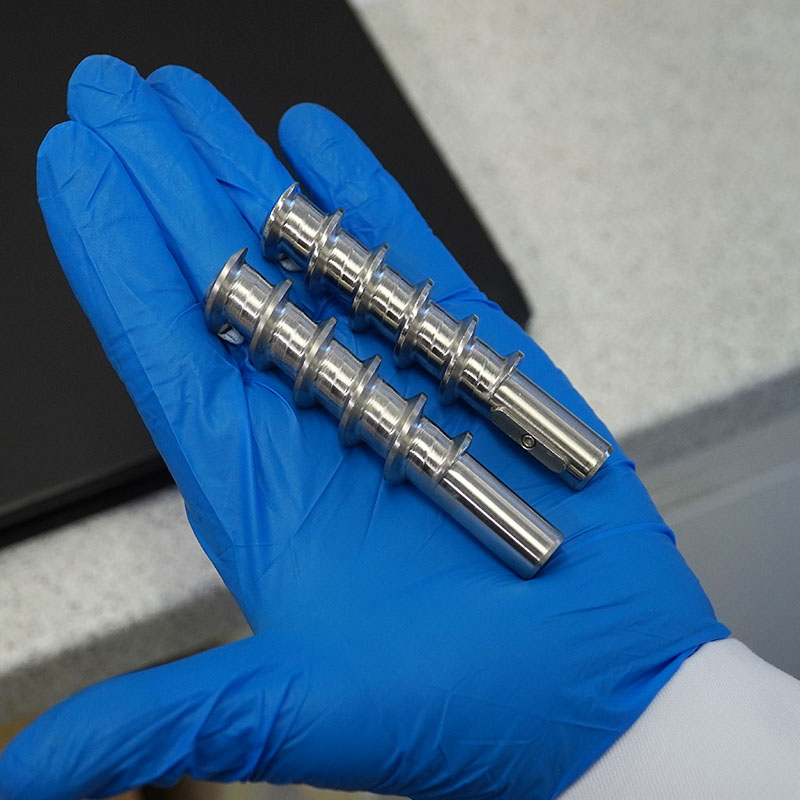

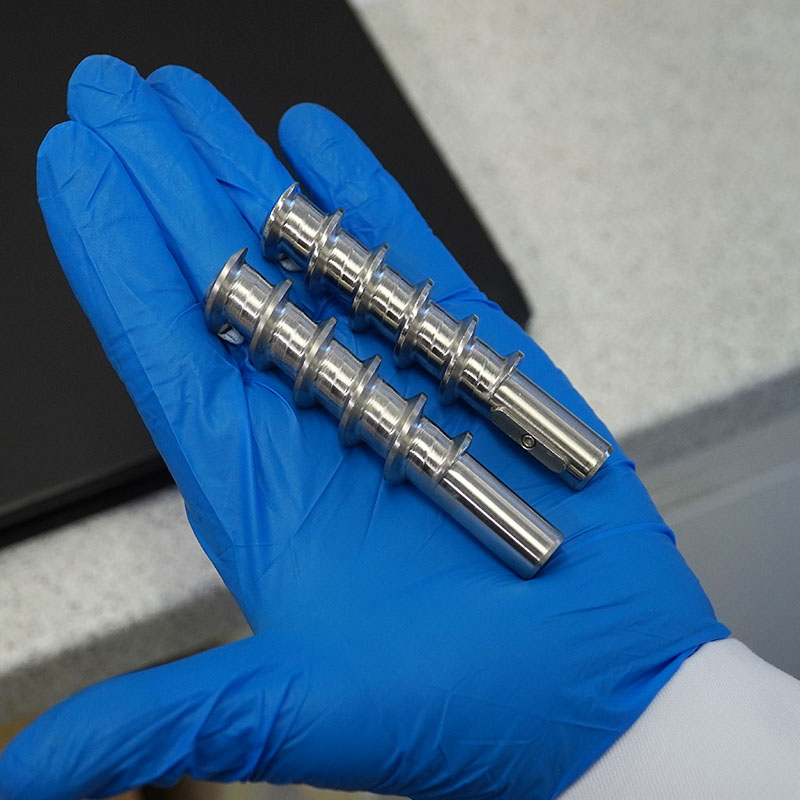

The CML also comes with 2 different extruder screws, as standard, to compliment the different dies and materials you may be working with. You can choose which screw works most effectively with your formulation.

Contact us for additional advice on whether this could be beneficial to you.

We can manufacture and supply a range of specialist “non- circular” die hole designs including dies with trilobe and quadrilobe hole shapes. These can be various designs and configurations according to your requirements.

If you are working with catalysts or products for gas adsorption then having die plates designed to increase the surface area of your extrudate is often a must have

Increase the surface area to volume ratio (SA/V) of material produced using different die designs by around 30%.

Contact us for a discussion if you have specific requirements.

We can offer a wide range of different spheronizer disc patterns.

If you need to know more detail about exactly what kind of discs we can offer, please contact us for details of the cross

hatch and radial patterns that are available.

If at some point in the future there is the possibility that you may wish to work with materials that are known to be sticky then applying to the spheronizer disc and the interior of the drum a coating of PTFE is a possible option. Let us know if this is of interest to you and we can arrange it for you.

Please call us without obligation.

+44 (0) 1258 471122Please call us without obligation.

+44 (0) 1258 471122