The process of spheronization consists of four key steps:-

- To optimize and achieve the right binder addition & mixing time for your formulation

- Mixing or granulation - a mixer or granulator is required

- Extrusion - an extruder is required

- Spheronization - a spheronizer is required

- Drying and possibly coating - a coater and drier may be required

This is all made simple by the Caleva suite of R&D equipment shown in the section below.

Quantify the Characteristics of your Formulation

- Reduce your formulation development time

- Optimize the characteristics of your formulation?

- Can you confirm that the same product from different suppliers behaves differently in your formulations?

- Would it be useful to be able to quantify the characteristics of samples taken from your granulator?

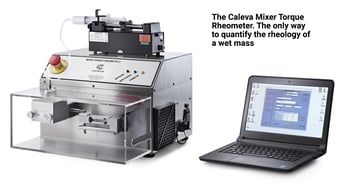

Mixer Torque Rheometer

Mix, Extrude, Spheronize and Analyse with a Single Bench-Top Unit

- Save benchtop space, time and materials with small batch sizes of 10 - 40 g

- Fast processing times means you can go from powder to pellets in 20 minutes or less

- Various bowls, blades, extruder screws, barrels, and die options available for different materials

- Multi Lab Classic's software and accessories can be upgraded after purchase to the Multi Lab Scientific

- Multi Lab Scientific has automated data acquisition, recipe management and automatic operation, motor load % reports, temperature monitoring and data export for in-depth analysis.

Multi Lab Scientific

Quickly Coat or Dry a Few Tablets, Capsules or Pellets

- From a single tablet up to about 50 tablets

- From a few grams to about 60 grams of small pellets

- From a single capsule to a "small handful" of pellets

- You can reduce the amounts of ingredients used whilst still producing meaningful results

Mini Coater Dryer

Leave A Comment