Is there a guide to the optimum Length to Diameter ratio of the extrudate fragments?

In the calculations used to demonstrate the data it is assumed that the extrudate is an infinitely long strand. In this case the length of the extrudate has no influence on the data shown. In reality, extrudate is not infinitely long and as the individual strands of the extrudate produced become shorter, the influence of the length will have an increasing influence on the SA/V. Taken to its conclusion, as the length of the individual piece of extrudate becomes shorter and approaches an infinitely thin slice then SA/V will increase towards an infinitely large figure. Clearly this situation will not arise but it does ask the question if, in practice, there is any length to diameter relationship that is empirically optimal.

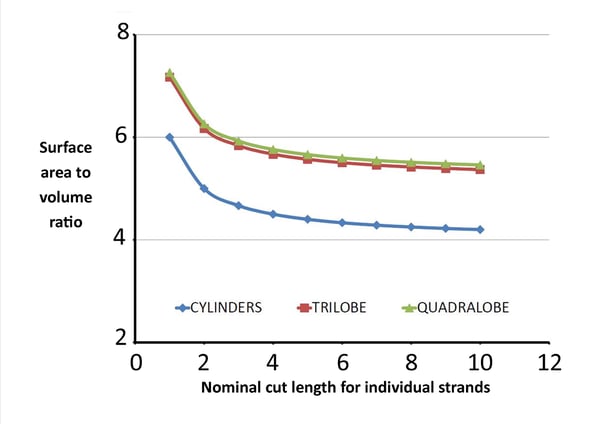

Figure 2 - The calculated effect on the Surface area to volume ratio produced by three different die configurations when the extrudate is cut to different lengths

The relationship between SA/V, as the extrudate length reduces is shown to be a relevant, but not a highly significant, factor in through the range of lengths that would be normally used in practise. A length to diameter ratio higher than 6 would not be a concern in relation to the SA/V ratio. Extrudate with a mean length to cross sectional area higher than 6 tends to reach a SA/V ratio that tends towards 4 with both quad-lobe and tri-lobe extrudate remaining in the range of around 30% higher.

With diameter to length ratios less than 6 the increase in SA/V between the cylindrical discs and the modified die holes becomes less and at a length to diameter of about 1 and the increase in the SA/V falls to about 20%.

The effect of air flow and operating efficacy (adsorption or catalytic effects) through any extrudate bed would be influenced not only by the SA/V ratio but also by the packing of the extrudate and the tap density of the material and both would be influenced by the length of the cut extrudate pieces. It is all these factors and not only SA/V ratio that will determine the final operation functionally of the material in a column or bed. The confirmation of the actual utility would need to be tested on a product by product and case by case study.

This data generation would require further studies. However, what is clear is that the use of Tri-lobe or Quad-lobe shaped die hole would not only potentially enhance the efficacy but that extrudate of varying lengths would not in practice have any obvious disadvantages and trials are worthwhile in each specific case. It is recommended that without additional product specific recommendations a specific length to diameter ratio is maintained between 2 and 6.

Leave A Comment