Using the Caleva Multi Lab it is possible to extrude of small quantities of catalytic material, whilst increasing the surface area to volume ratio of the extrudate produced.

It is possible to work with very small batches or product (from about 10 g to about 50 g) and increase the surface area to volume ratio of the dried extrudate being produced. The increased surface area of the extrudate is produced by extruding the active material through a die with a trilobe or quadralobe (quadrilobe) holes in place of the traditional round holes.

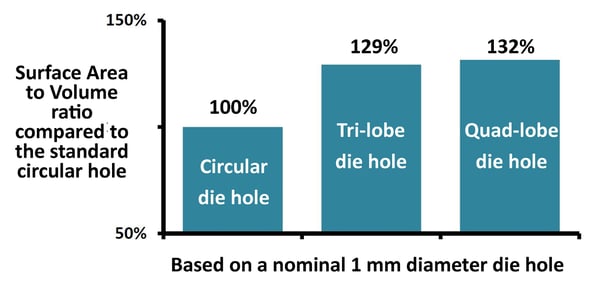

After drying, the use of the Caleva trilobe or quadralobe dies will increase your extrudate's surface area to volume ratio by about 30%.

In conjunction with the use of Caleva's Variable Density extrusion dies, in addition to increasing the surface area the porosity, viability and hardness of the materials produced can also be varied by the user.

The die shapes available with the Caleva Multi Lab are:

- Cylindrical

- Trilobe - potential to increase your surface area by approximately 29%

- Quadrilobe - potential to increase your surface area by approximately 32%

These shaped dies have been developed for use with the extruder attachment of the Caleva Multi Lab. The same technology can also be used in the slightly larger benchtop Variable Density Extruder and our large production Twin Screw Variable Density Extruder.

The range of Caleva extruders can be scaled up from R&D samples of a few grams up to production rates of about 150 kg per hour.

To find out more please view Caleva's range of bench-top laboratory extruders, or our scale-up extruders.

Leave A Comment