Download a PDF version of this guide at the bottom of the page

What is Spheronization?

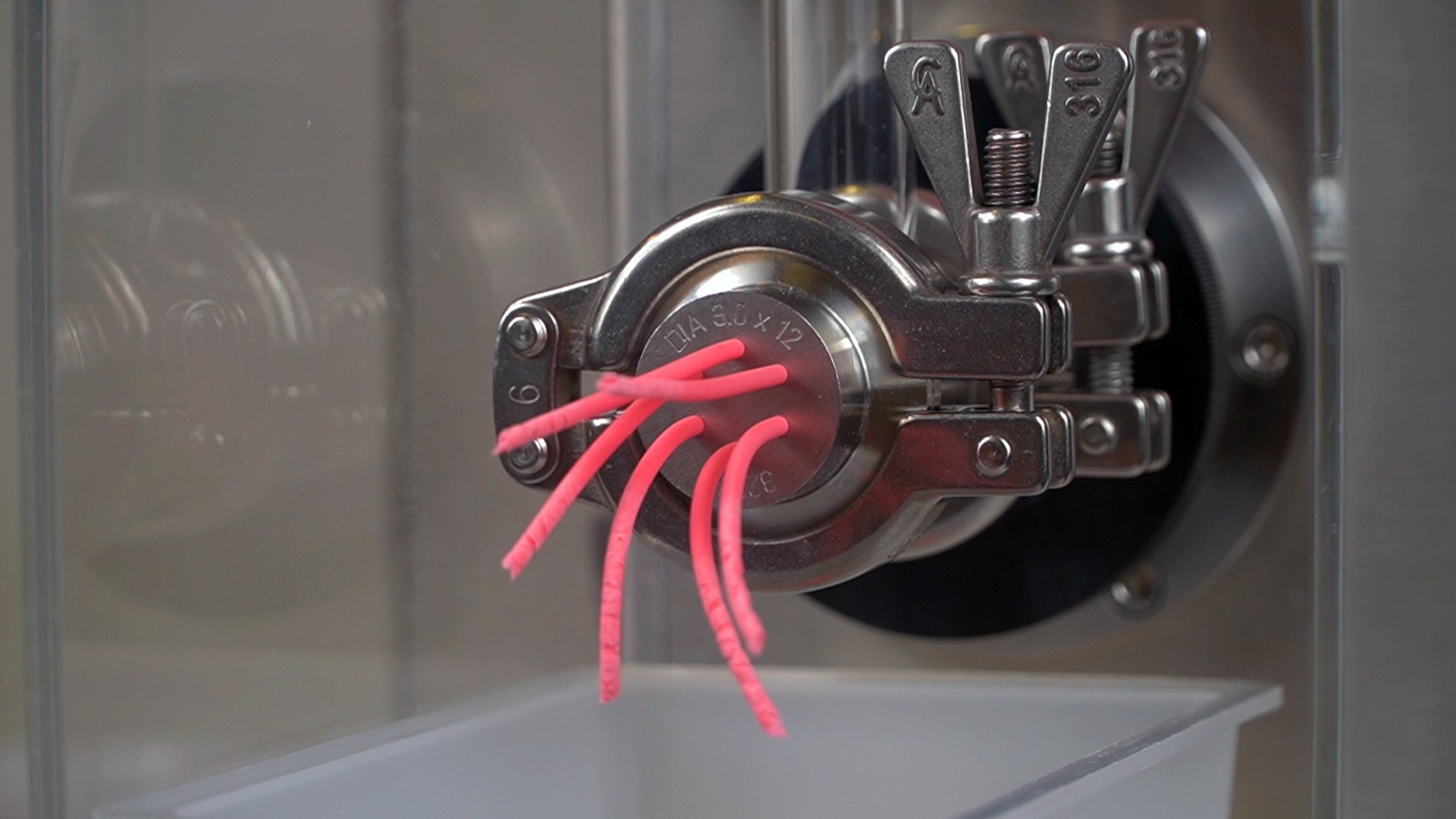

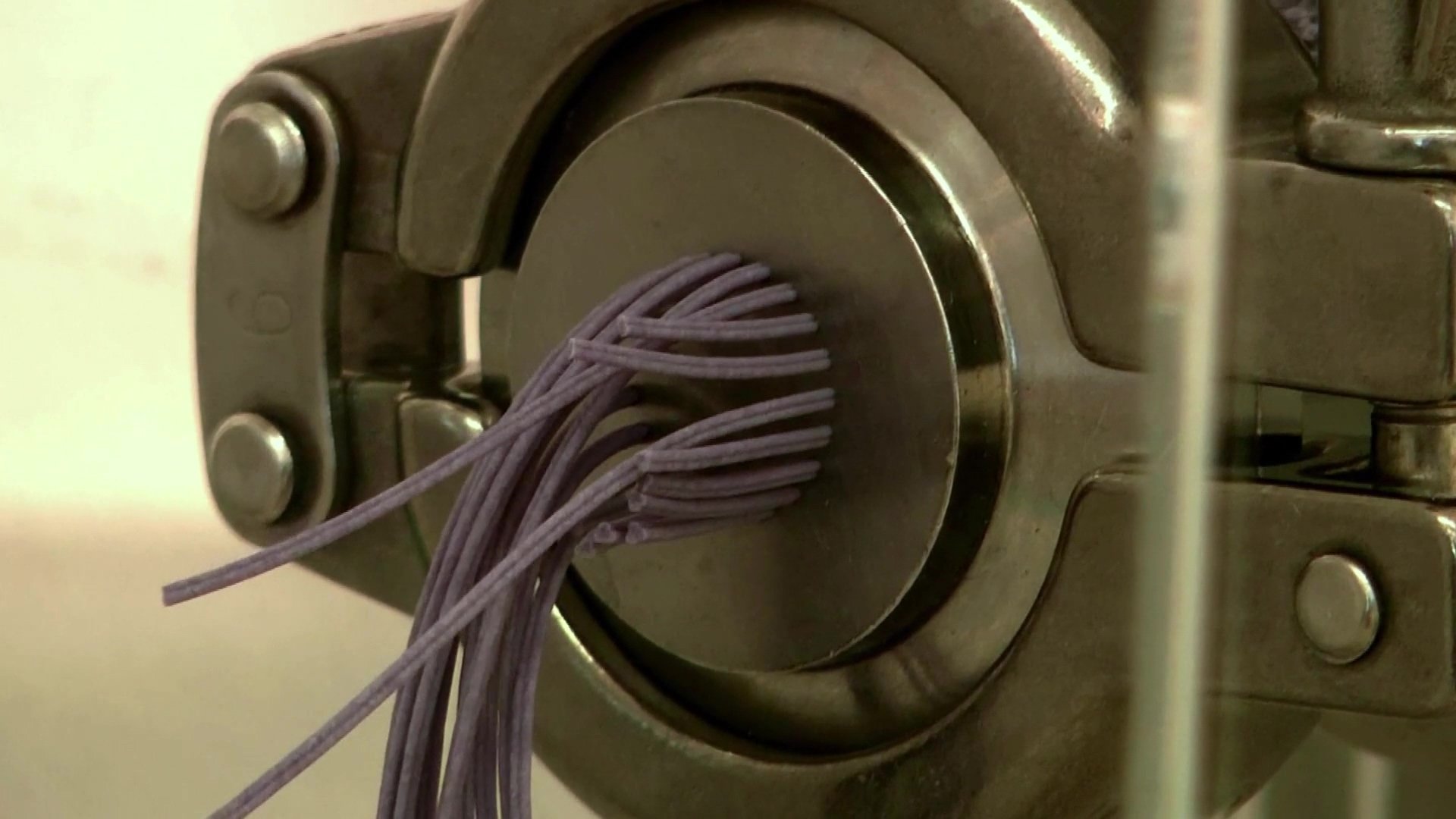

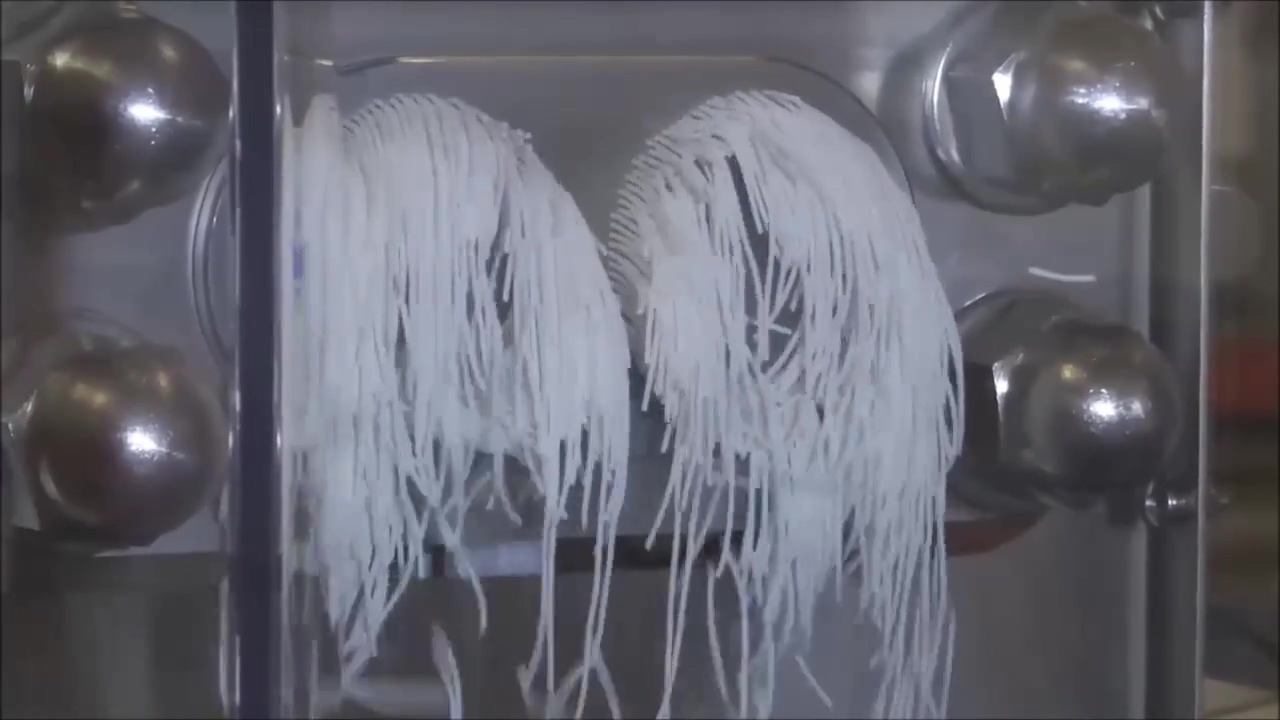

Spheronization (sometimes referred to as Marumerization) is the process where extrudates (the output from an extruder) are shaped into small rounded or spherical pellets (spheroids, beadlets). The pellets usually vary in size from 0.4 to 3.0 mm. Pellets can be used in a wide variety of industries.