The rapid integration of artificial intelligence (AI) and machine learning (ML) into pharmaceutical research and manufacturing is reshaping how formulations are designed, tested, and optimized.

Knowledge Base

Overcoming Consistency Challenges in the Iron Making Sector

Caleva's International Sales Manager Steve Mate visited the Department of Chemical Engineering at Osaka Metropolitan University to find out how the Mixer Torque Rheometer (MTR) is being used.

Measuring and monitoring your formulation

Did you know that the Mixer Torque Rheometer (MTR) is designed to carry out 3 separate experiments essential to your formulation development and production?

Book a live online demonstration with Caleva

Are you interested in one of our products and would you like to see it in action?

We provide free R&D system demonstrations live online via video conference wherever you are in the world.

Scott Humphries or Steve Mate will demonstrate and explain advanced equipment features and allow you to see the processes that are relevant to your work. It will be an ideal time to discuss any challenges you...

Shaped Catalyst Body Preparation with MTR and Caleva Screw Extruder

Shaped Catalyst Body Preparation. Zeolite HZSM-5 (ACS Materials, M38) was mixed as a dry powder with alumina (Sasol, Catapal D (Boehmite)) and the required amount of Milli-Q water to ensure an optimum solid-to-liquid ratio for extrusion (measured using a Mixer Torque Rheometer, Caleva). The paste, containing a ratio of 70:30 wt % zeolite:binder, was extruded using a Mini-Screw Extruder (Caleva),...

Caleva explain the basic Mixer Torque Rheometer concepts - Video

The MTR can process from 10g to 25 g of your material, depending on the formulation, meaning barely any material is wasted in experiments. The machine will very quickly tell you the ideal amount of liquid to add. The user may have a start point in mind but this may result in a formulation that is too wet or too dry. The iterations may be repeated, but this can be wasteful in terms of materials...

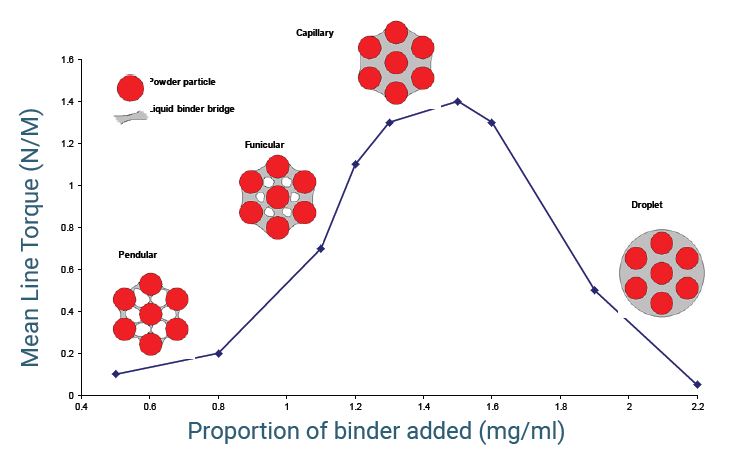

Opportunities for Mixer Torque Rheometry

Wet granulations are a useful precursor to many solid dosage formulations and as such are widely used in the pharmaceutical industry. Because of the diverse nature of pharmaceutical materials, granulation is often employed as an intermediate process to enhance flow and compaction properties and improve the final product performance. The properties of a wet granule have a critical effect on the...

How much product should be used in the MTR and how accurate is it?

How much product do you use? The answer is that this is always product specific. This is demonstrated in this article. In these experiments the MTR is used in the multiple addition mode whereby increasing binder content is automatically added to different masses of product. The Caleva Mixer Torque Rheometer. The only way to quantify the rheology of a wet mass. The MTR has, for many years, been...

Can temperature during granulation influence formulation consistency?

The temperature of the mix during granulation processes is generally considered to be of minor significance in both formulation development and in large batch granulation despite the fact that in some locations ambient temperature can change significantly during the course of a working day.The MTR manual states that the bowl should be allowed to return to room temperature after washing. The...

A Tool for Pre-Formulation Assessment of Excipients

Excipients from different batches or vendors may vary in quality and it is often necessary to perform pre-formulation assessment for each new batch of excipient received.

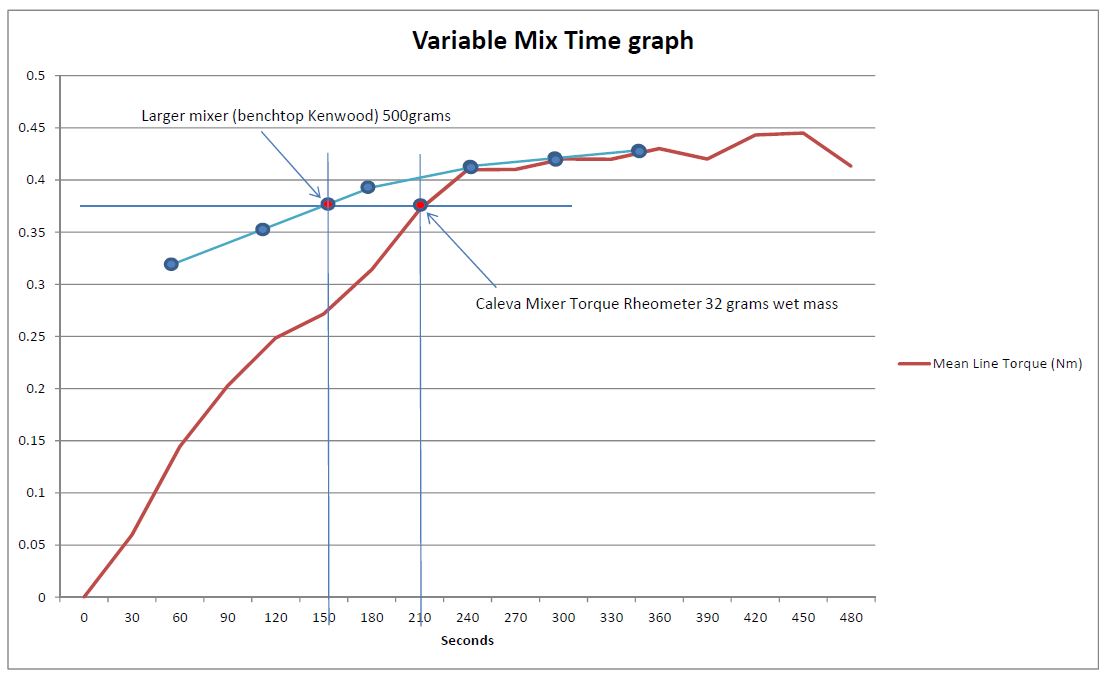

How long should I granulate my materials?

Variable Mix Time Test

It is well-known that a minimum amount of mixing is required to ensure consistent and repeatable product characteristics. What is often less considered is the possibility of over-mixing the product so that the characteristics of the resulting formulation undergo a change.

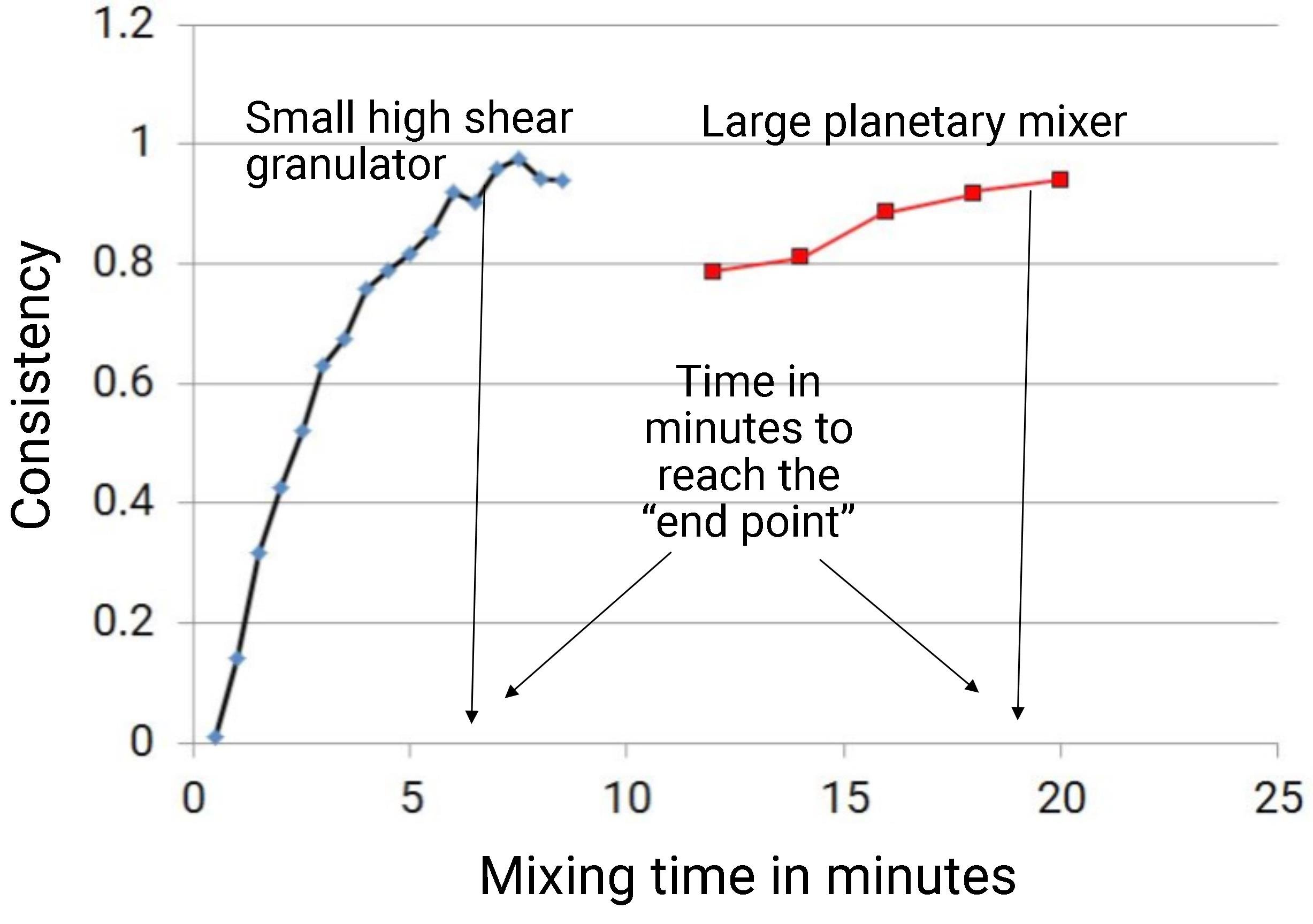

How Do You Ensure Consistency During Scale Up?

The Mixer Torque Rheometer's Consistency Test

To ensure consistency is maintained during scale up and production, the Mixer Torque Rheometer can be used to perform a quick and simple test which monitors the consistency of the wet granulation during the mixing phase. This test can be used whether you are working with continuous or batch production.

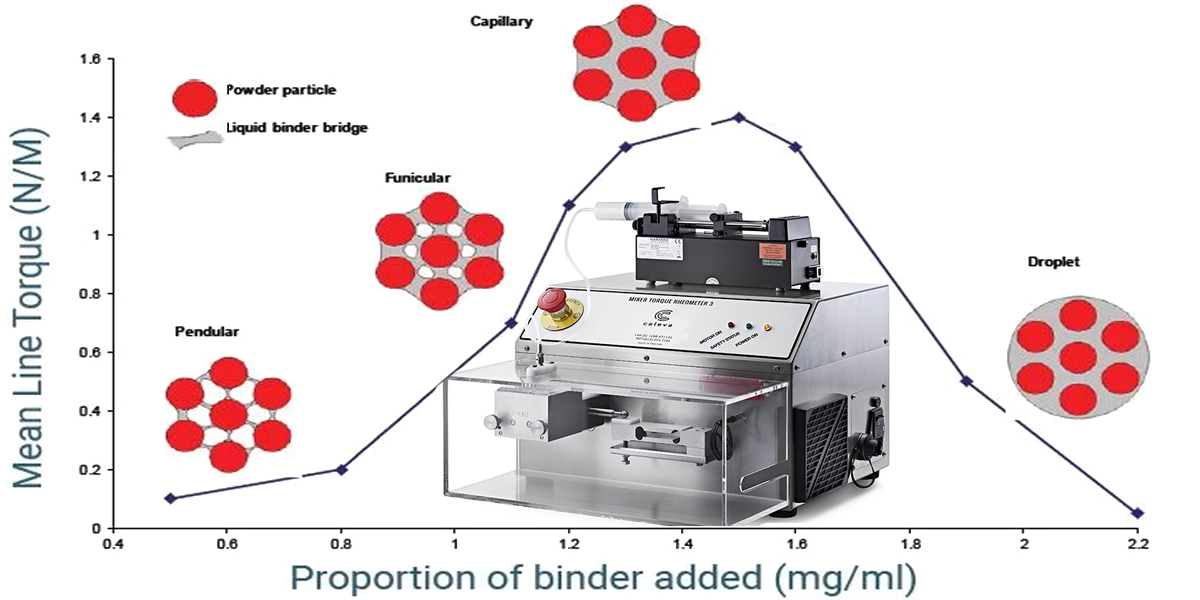

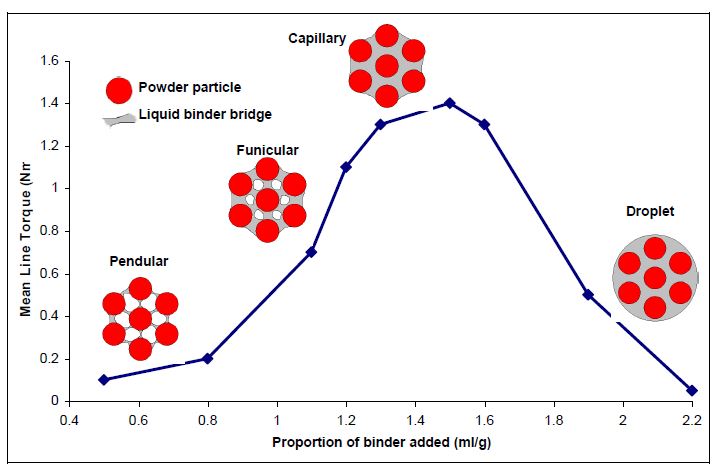

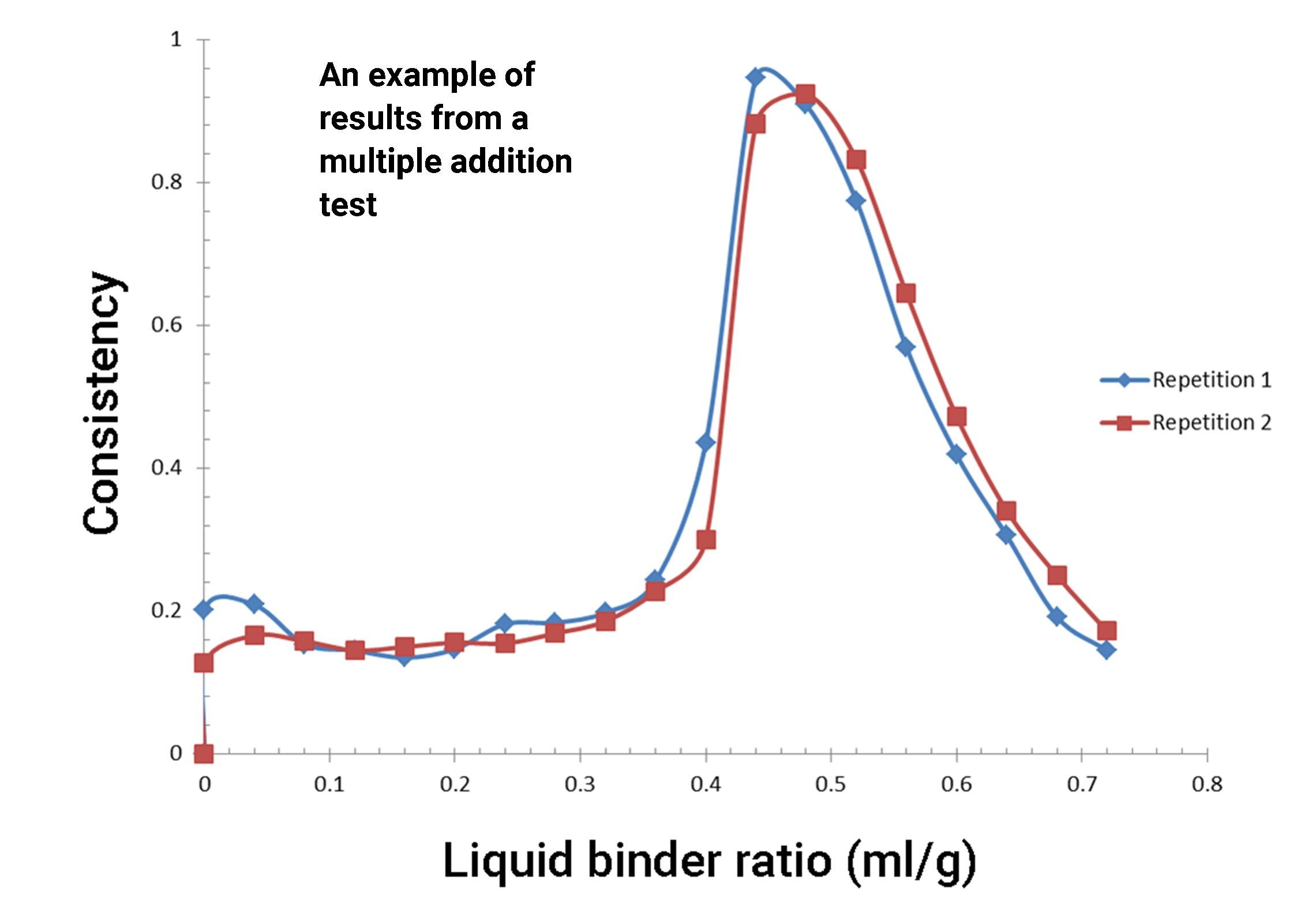

Formulation development - determine optimum powder to binder ratio

Multiple Addition Test

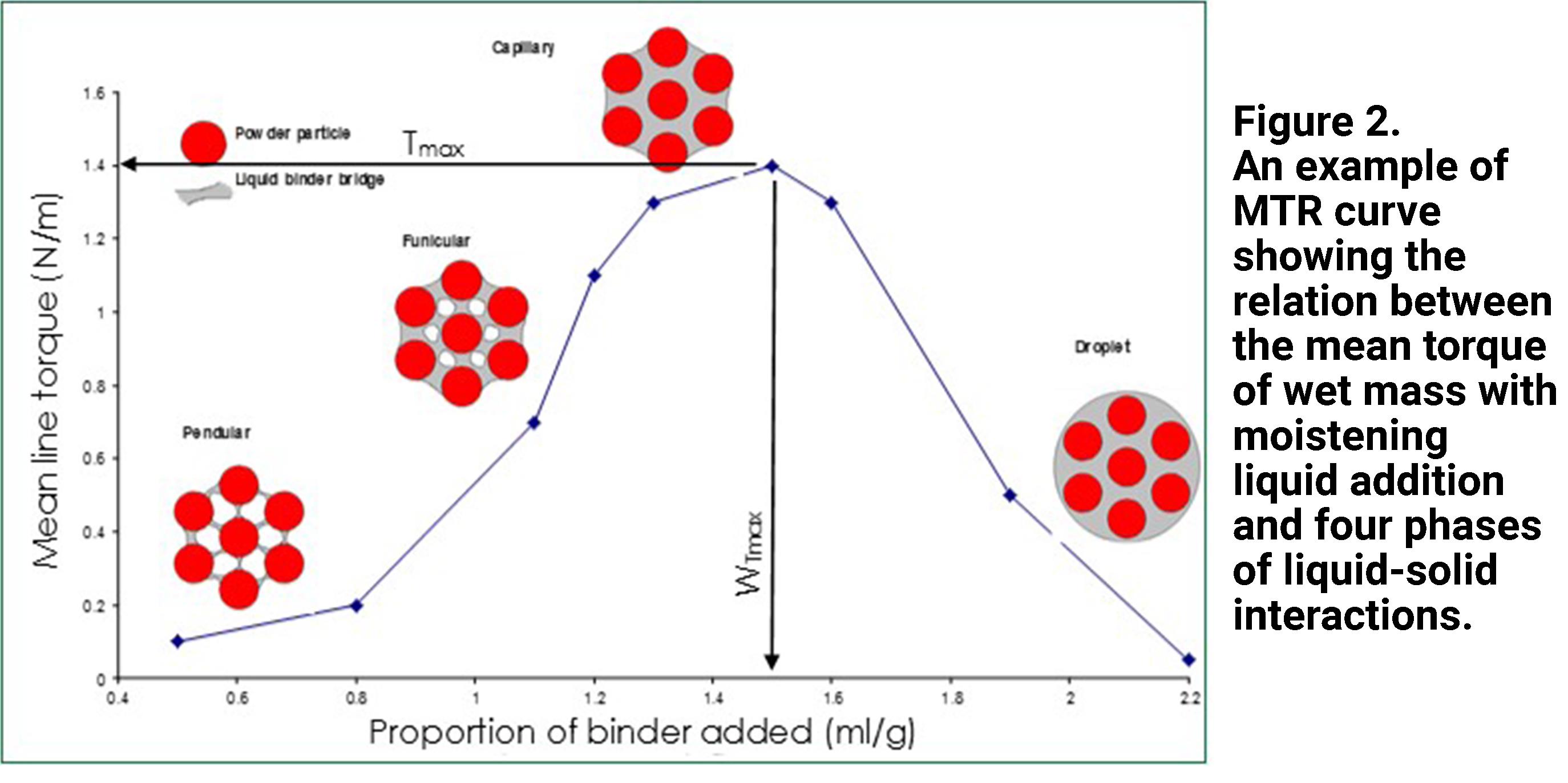

Binder liquid is added to a dry powder mix and the consistency is measured as the mixing and addition of binder progresses.

The consistency of the mix is measured at regular periods so that the relationship between the amount of liquid binder added to the mix and the consistency in the resulting formulation can be accurately shown.

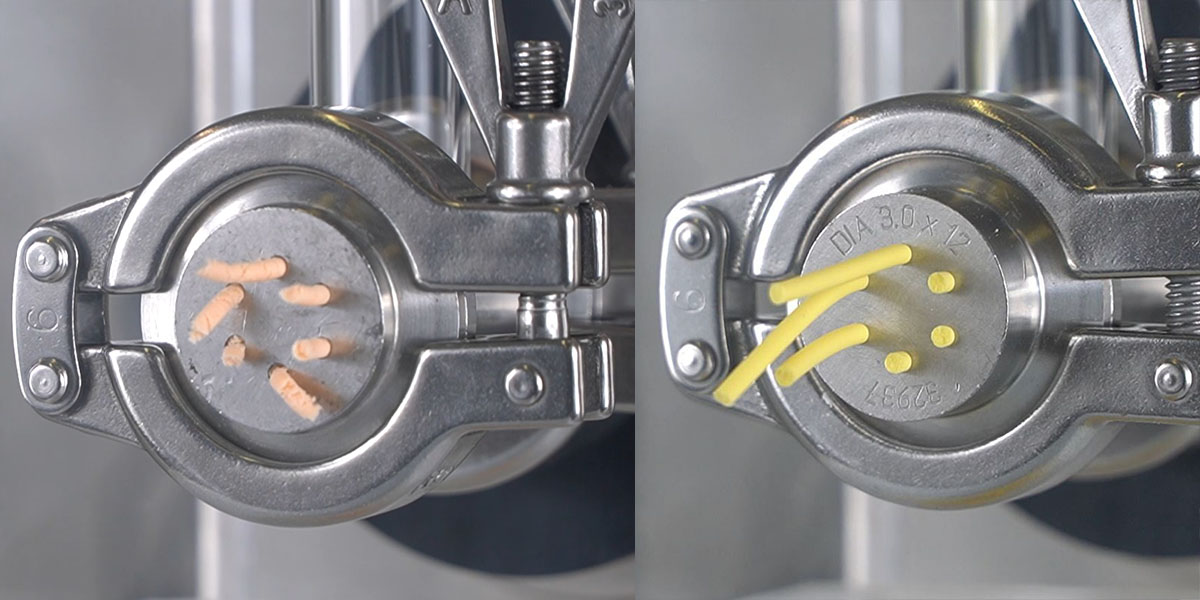

What characteristics should my extrudate have?

Extrusion and spheronization is not always completely straightforward. A formulation required for spheronization needs to go through the following processes and achieve the following properties.

How to produce consistent formulations from different mixers

Customer Quote: Mr. K.S (Aurobindo)

"It is exciting to see the correlation between the two graphs and granulation end point".

With a major pharmaceutical manufacturer, together we characterised all their various mixers to produce a consistent formulation.

To identify three important characteristics for wet mass materials, namely:

- The Optimum moisture point

- The mixing time required to reach the...

Do excipients purchased from different vendors behave in the same way?

The Mixer Torque Rheometer can be used to assess the behaviour of excipients purchased from different suppliers.

Background

Excipients from different batches or vendors may be variable in quality and it is often necessary to perform pre-formulation assessment for each batch of excipient received. In some cases, excipients from different vendors require comparative assessment of their equivalent...

The Caleva Family of Laboratory Equipment

Whilst you may have heard of Caleva and any one of its flagship pieces of equipment, we'd like to introduce you to the family of Caleva laboratory equipment that you may find helpful for your application in your industry sector. Choose one process or choose all of them. Select further functions as you need them. This adaptable and future proof suite of equipment will allow you to obtain proof of...

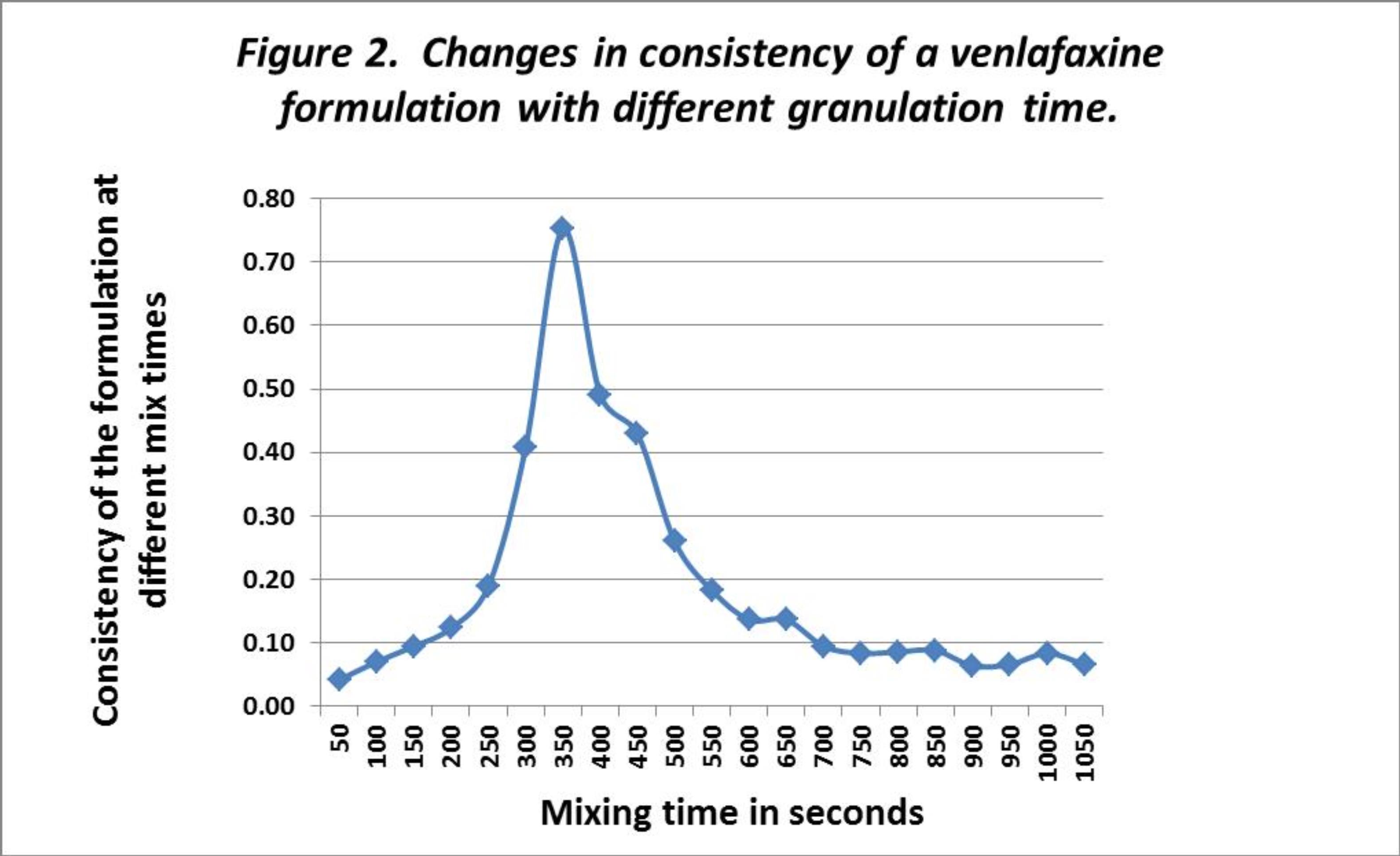

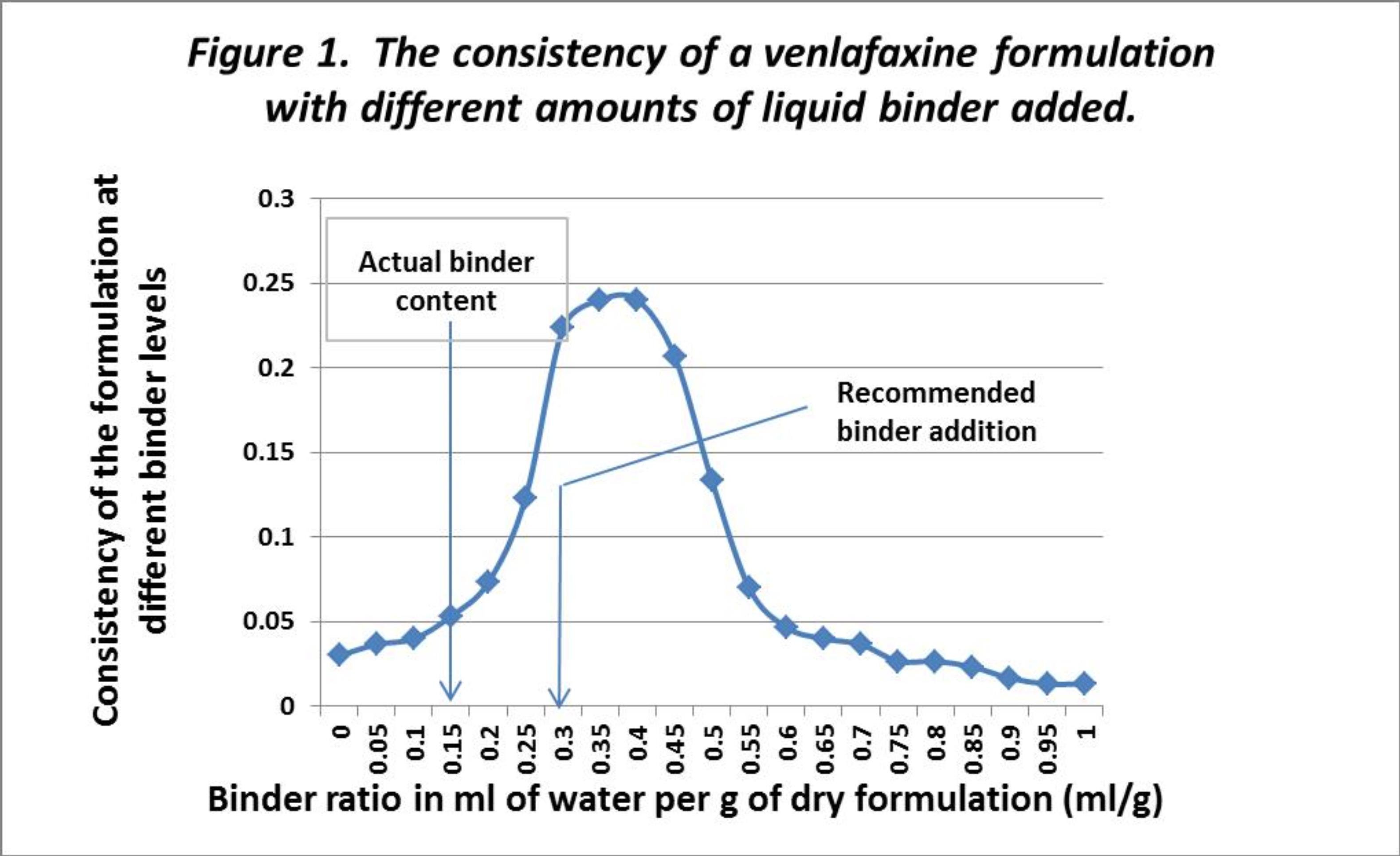

Inconsistent spheronization results with difficult active ingredient?

The following case study demonstrates how the Caleva Mixer Torque Rheometer. The MTR-3 was an invaluable aid in a specific case. A manufacturer of generic Venlafaxine pellets was experiencing inconsistent results from their manufacturing line. The resultant product was variable in both usable yield (weight of acceptable pellets as a % of weight of granulation made), and dissolution profile. The...

Mixer Torque Rheometer used with Food Powders

Research Article University of Padova where their Caleva Rheometer was used

Abstract

Vegetable soups are complex mixtures containing vegetables in different percentages, thickeners, salt, fat, and emulsifying/wetting agents. When prepared as dehydrated powders in convenience foods, they need to be rehydrated before consumption and this can lead to formation of undesired lumps when...

The Importance of End Point Detection Consistency

This world is not only for us. Can you imagine world had no animals, what would it be like? Would the trees be green? Without birds or squirrels, less trees would grow. There would be no pets, no flowers and no bees. If even one part of our ecosystem is removed, we will all die. Without animals, we will surely go extinct.