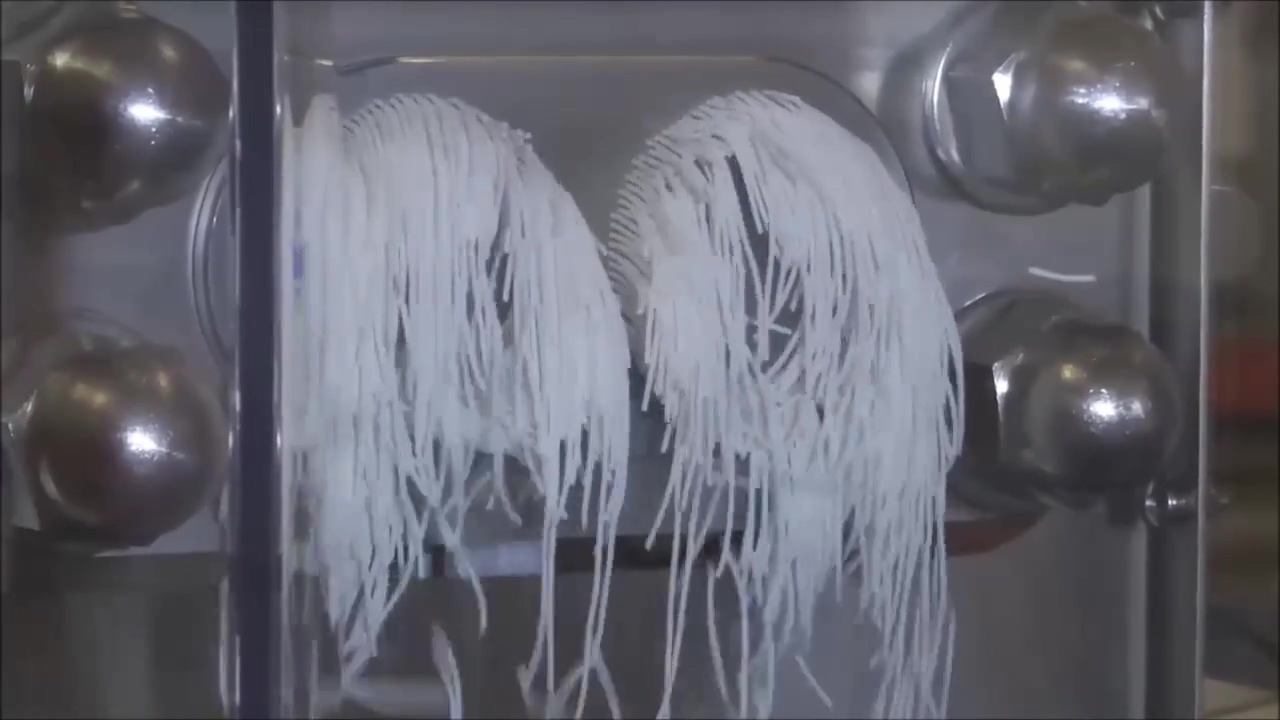

Our new High Viscosity Mixing Blades, designed for making those sticky, viscous, difficult, granulations much simpler. Our design team have been working tirelessly to come up with a solution to a constantly asked question.

Knowledge Base

What type of pharmaceutical or catalyst extruder do I need?

All extrusion processes require the generation of pressure within the material to be extruded. When materials are put under pressure heat is generated. This cannot be avoided but different extrusion types generate different amounts of heat. There are basically three different types of extruder and the one chosen may have far reaching implications on production operations. It is important that the...

Mix sticky, viscous and difficult granulations

High Viscosity Blade & Bowl set from the Caleva Multi Lab. Mix and blend small quantities of difficult materials using the special high viscosity bowl and blade attachment set built for the Caleva Multi Lab.Our high viscosity mixing bowl and blade set is designed for mixing and blending of small quantities (10 to 50 g) of those more difficult and more viscous mixtures when the high shear standard...

Catalyst Pellets cracked! The strange apple sauce method

Over the past couple of years I have worked with a huge number of chemical engineering teams, trying to crack the optimum base for a catalyst pellet. After hours of trials and research, I am pleased to say, we’ve done it!

Spheronization Barrier Technique from Caleva

OK, so this was a tip I discovered a while back, but now it’s becoming more and more beneficial for me in practice when working with sticky, viscous materials. Perhaps this will help you too?