The rapid integration of artificial intelligence (AI) and machine learning (ML) into pharmaceutical research and manufacturing is reshaping how formulations are designed, tested, and optimized.

Knowledge Base

The Importance of Understanding the Rheology of Wet Mass in Tablet Formulation & Manufacture

In the world of pharmaceutical manufacturing, achieving consistently high-quality tablets is a top priority.

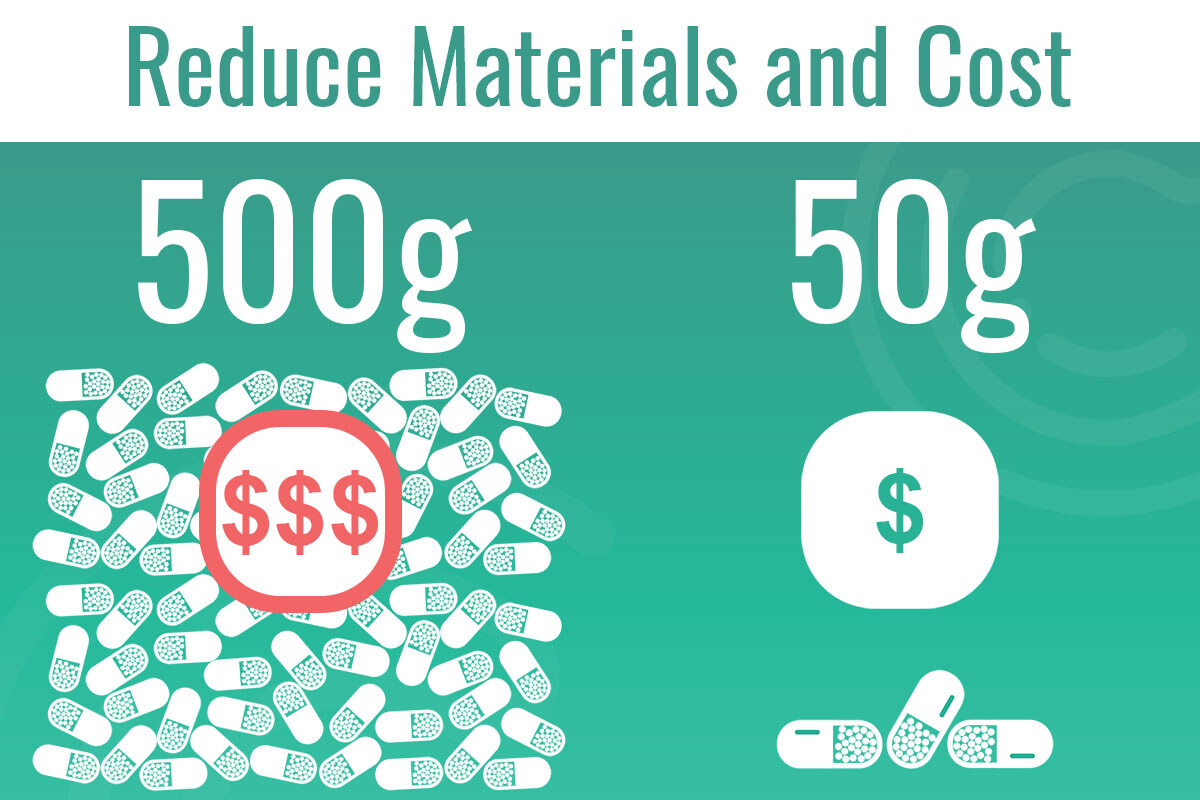

Small is Beautiful: Miniaturisation in Pharmaceutics

The goal of accelerating discovery, development, and delivery of new products in the Pharmaceutical and allied industries is continual. In recent times significant effort has been made to reduce the scale at which research and development (R&D) is possible.

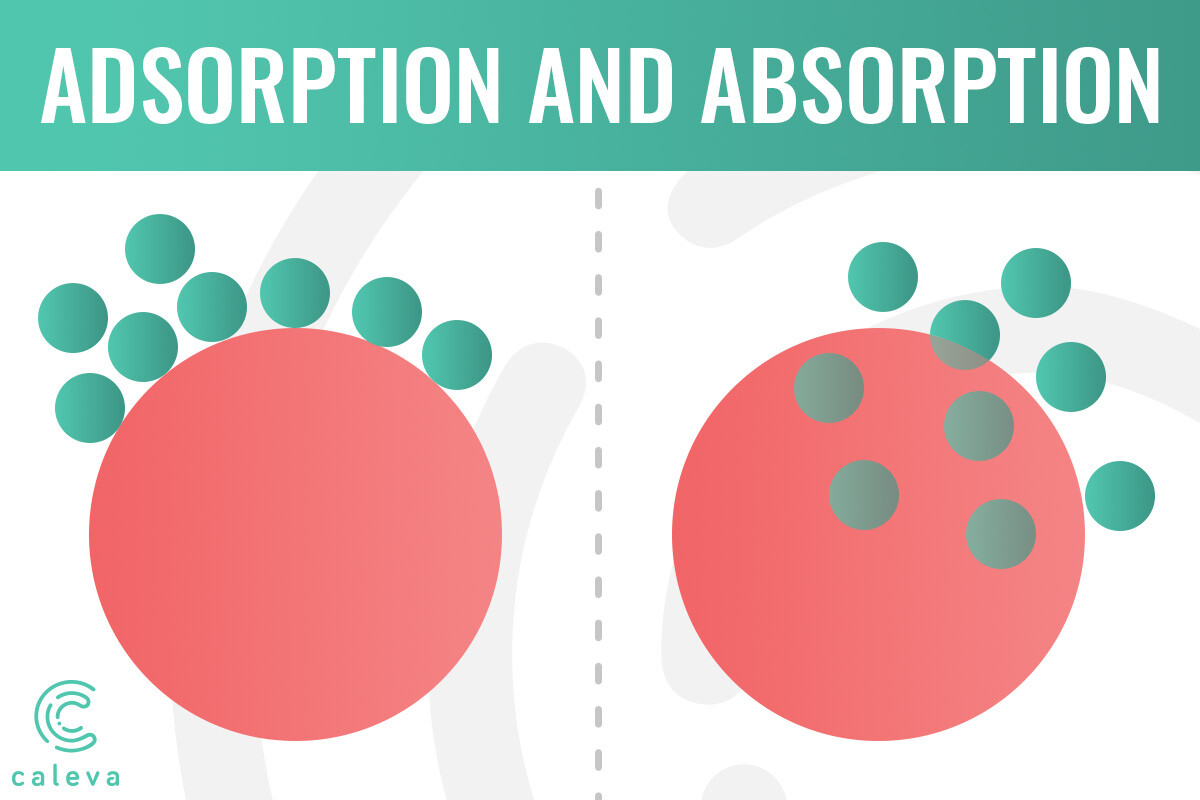

The Unsung Heroes: Adsorption & Absorption in Extrusion-Spheronization

Extrusion-spheronization is a cornerstone technique in pharmaceutical manufacturing, transforming drug substances and excipients into uniform, spherical granules (sometimes called pellets, spheroids or beads).

How to Reduce Your Formulation Development Time

Discover how to cut your formulation development time in half with the Caleva Multi Lab and its wide range of variable density dies.

Does the Caleva Mixer/Granulator/Blender allow me to mix and test small batches of product?

We are frequently asked for information about the ability of the smallmixer/granulator/blender, a must have tool for any laboratory needing to complete these processes quickly with small sample sizes. Recent trials provide new information about the capability of the Caleva mixer/granulator/blender (MGB) and its ability to act as a stand alone mixer when mixing powder samples of different sizes...

Caleva Study on the Importance of Granulation

Our customer, a major pharmaceutical, biotech & nutraceutical manufacturer with an extensive portfolio of products. For reasons of confidentiality we do not name them.

One of our Production Extruder & Spheronizer Systems for manufacturing on a large-scale was used in trials by the manufacturer, but the pellets produced were not acceptable. As the product was already registered, the composition...

A better way to granulate with your viscous and sticky materials

Our new High Viscosity Mixing Blades, designed for making those sticky, viscous, difficult, granulations much simpler. Our design team have been working tirelessly to come up with a solution to a constantly asked question.

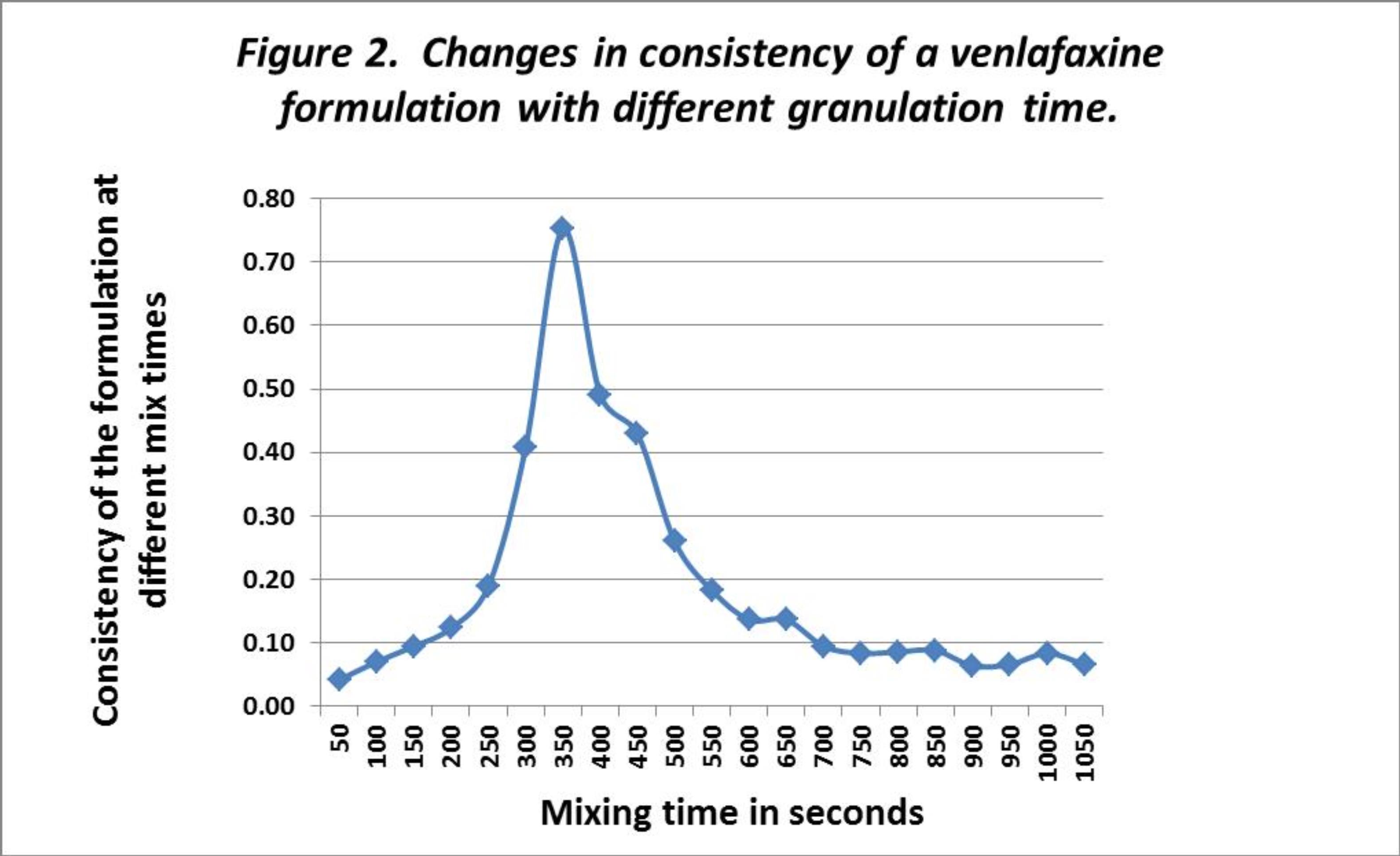

How long should I granulate my materials?

Variable Mix Time Test

It is well-known that a minimum amount of mixing is required to ensure consistent and repeatable product characteristics. What is often less considered is the possibility of over-mixing the product so that the characteristics of the resulting formulation undergo a change.

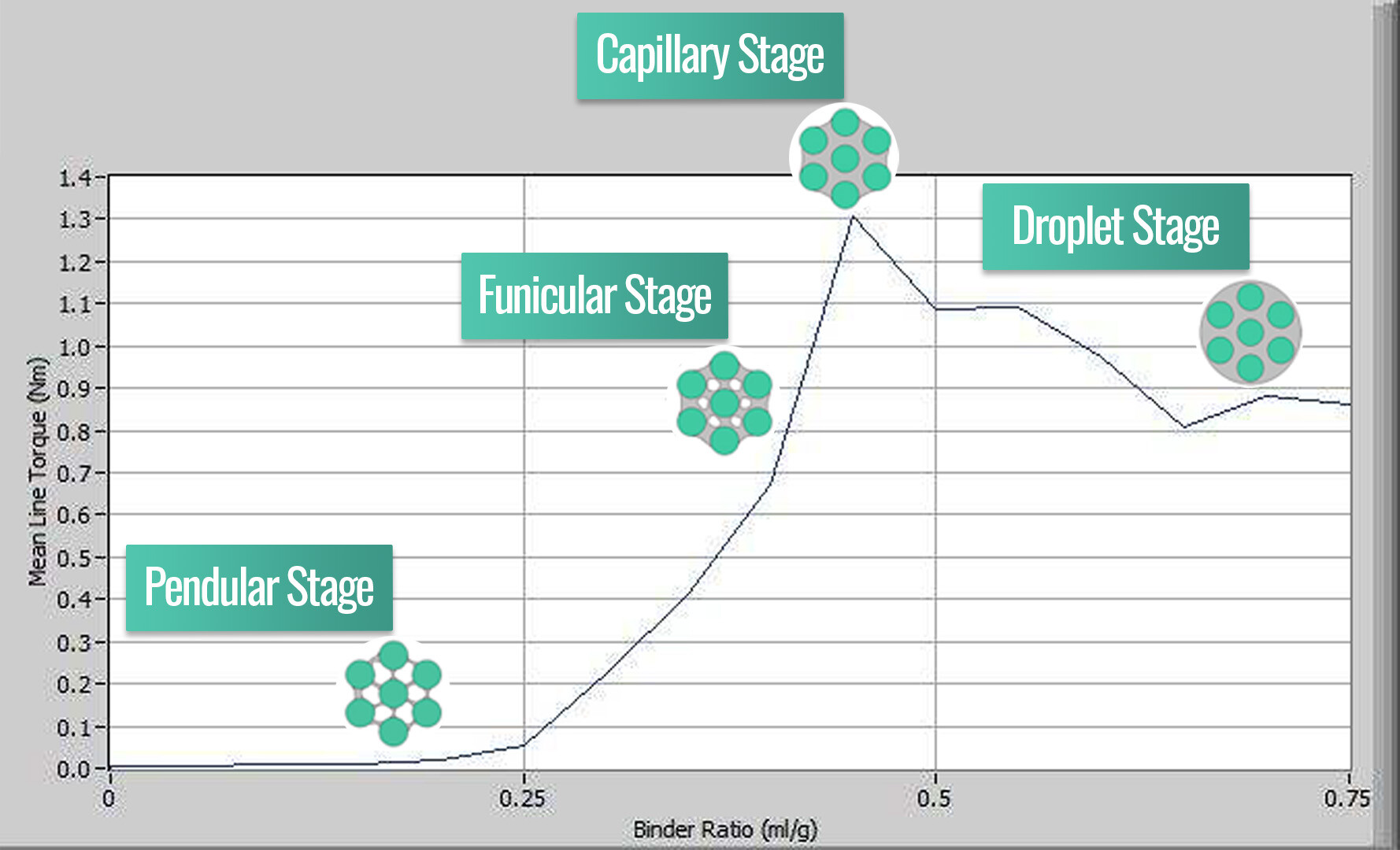

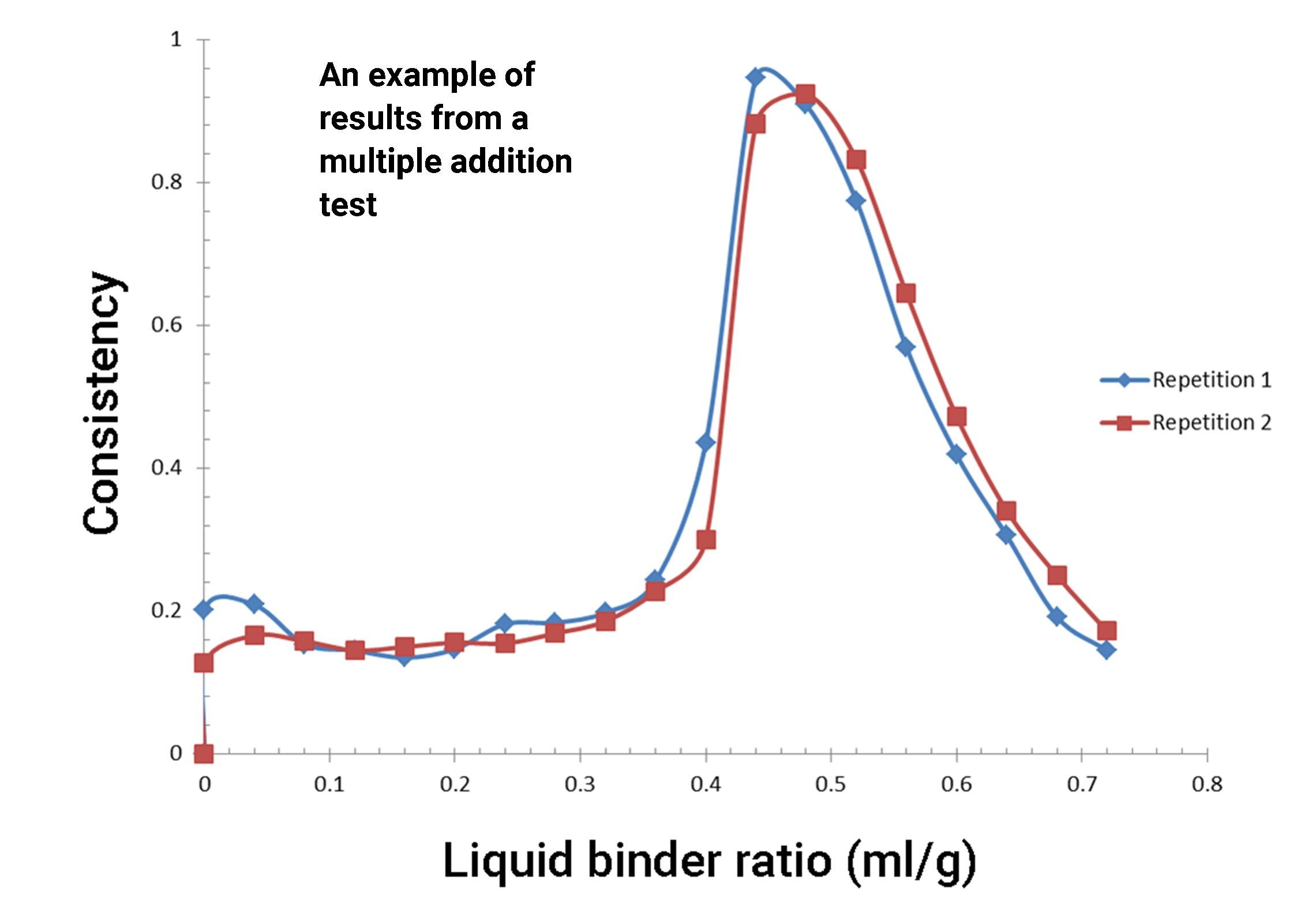

Formulation development - determine optimum powder to binder ratio

Multiple Addition Test

Binder liquid is added to a dry powder mix and the consistency is measured as the mixing and addition of binder progresses.

The consistency of the mix is measured at regular periods so that the relationship between the amount of liquid binder added to the mix and the consistency in the resulting formulation can be accurately shown.

Can I spheronize a granulation and skip the extrusion process?

In some circumstances it is possible to omit the extrusion stage, but the results may not be what you need.

It is dependent on what you need to achieve with your result and what you want to do in the next phase of the project. Whether or not you decide to include the extrusion stage will depend on what you want to achieve with your project.

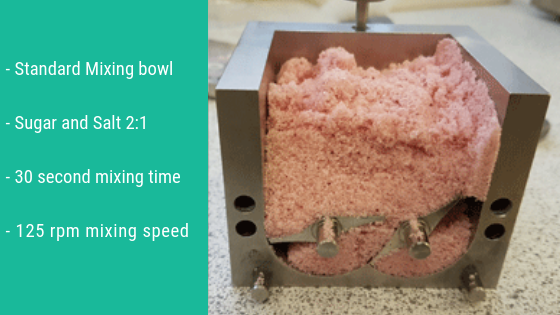

Mixing trials with a Caleva Mixer Granulator and difficult materials

Two different products were tested to help a customer who was finding some difficulty in obtaining homogeneous mixes of small volumes. These materials were considered difficult to mix to a homogeneous state in the batch sizes required.

PRODUCT 1, TRIAL 1

A mix of sugar and salt in the ratio of 2:1

A batch of 100 grams of household sugar was weighed and added to the mixing bowl, together with a...Mixing and granulating small batches

The Caleva Multi-Lab (CML) is capable of performing 3 different processes: Mixing, Extrusion and Spheronization.

This article is about the mixing and granulation phase of the process.

The multi-lab works with a large range of materials from pharmaceutical materials and catalysts, to agricultural products.

The granulator/mixer

The mixer attachment blades thoroughly mix the liquid binder with the...