Caleva's International Sales Manager Steve Mate visited the Department of Chemical Engineering at Osaka Metropolitan University to find out how the Mixer Torque Rheometer (MTR) is being used.

Knowledge Base

Equipment for the manufacture of pellets

Switch quickly between different materials with this easy to clean CE marked, top quality extrusion and spheronization system. An example of reliable and efficient British engineering at its best - this is the best option for your pellet production and is backed by the highly acclaimed support from Caleva Process Solutions.The Caleva system gives you the ability to vary the density of the...

Production Capacity Estimates for Extrusion and Spheronization Systems

We are often asked about the production capacity of our extrusion and spheronization systems. To provide this information there needs to be an understanding of the process parameters that will be used and that have been determined at the development stage. With that information, the advice that we give can be both meaningful and useful in the planning stages.If you have proven your concept at the...

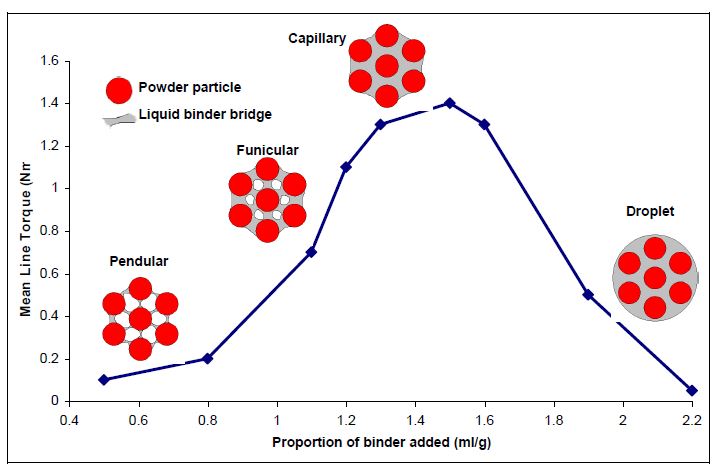

Opportunities for Mixer Torque Rheometry

Wet granulations are a useful precursor to many solid dosage formulations and as such are widely used in the pharmaceutical industry. Because of the diverse nature of pharmaceutical materials, granulation is often employed as an intermediate process to enhance flow and compaction properties and improve the final product performance. The properties of a wet granule have a critical effect on the...

Do all extruders and spheronizers have the same level of performance?

Product yields (the percentage of the spheroids produced in a batch that are within the size range required) will never be 100%.

A better therapeutic effect with spheroids

In many cases the main reason for the use of pellets in the manufacture of products is for its controlled release properties. However there are reasons to believe that pellets or spheroids in any case can offer a superior therapeutic effect even when modified release is not the prime objective.

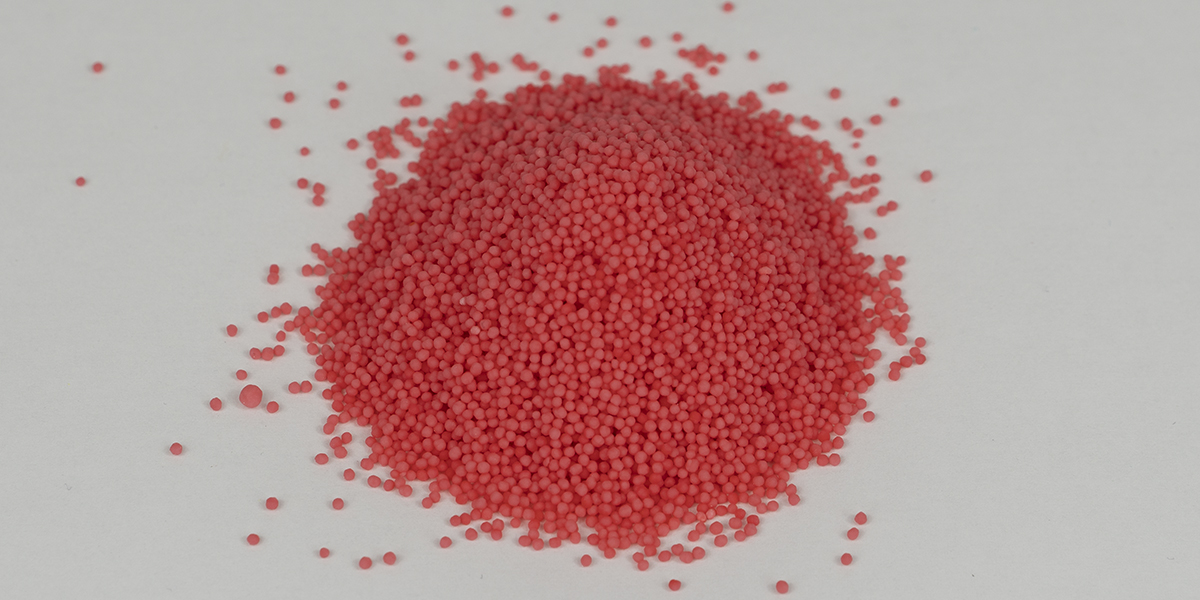

Examples of the terminology used in spheronization and marumerization

Spheronization, marumerization, pelletization and micropelletization all mean the same thing. The manufacture of products in small spheres (spheroids) for use in pharmaceutical (pharma) and catalyst industries. Within each batch the spheroids are of regular shape and size and are quite dense. The products produced by these processes can be called spheroids, spheres, micro-spheres, pellets,...

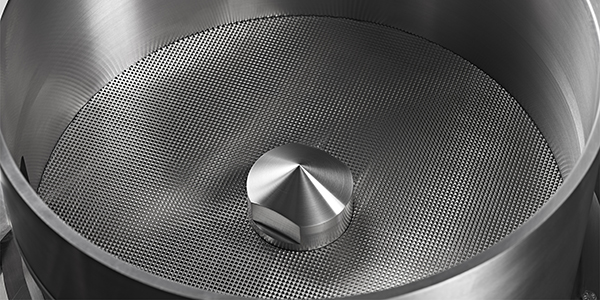

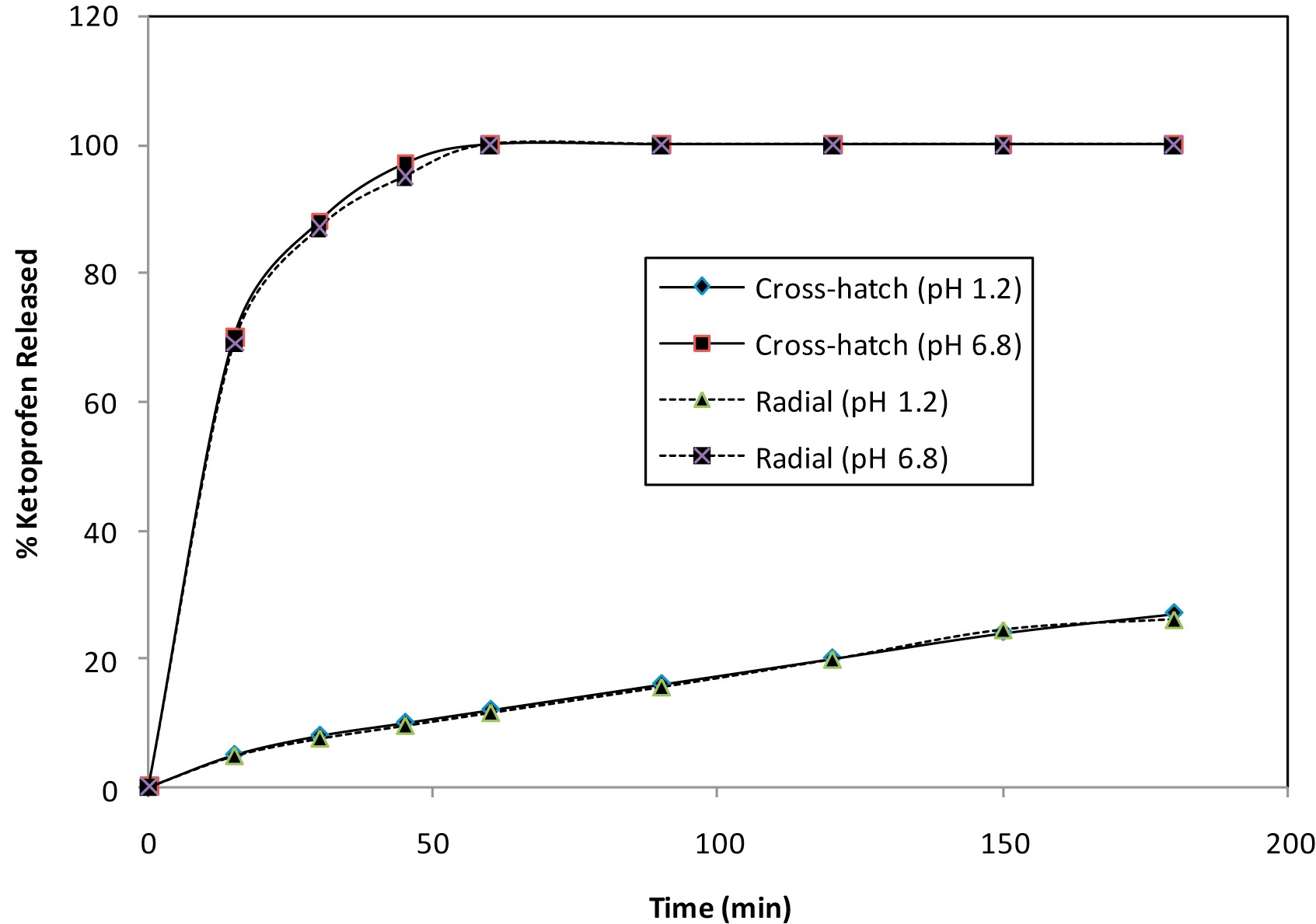

Effect of spheronizer plate design on the spheronization of ketoprofen

Abstract: Spheronization is a rapid process for production of microspheres. The process involves the dry mixing of drug with microcrystalline cellulose (MCC), which on subsequent wetting with water forms a plastic mass suitable for extrusion and spheronization. As in any pharmaceutical operation, large number of factors may affect the production of pellets, which can be related to formulation or...

Yield Problems in Production and Quality Control

One of the strengths of the Caleva Mixer Torque Rheometer (MTR-3) is that it can be used to verify the properties of wet powder mass samples taken during production in large scale mixer/granulator systems.