The recent European ban of titanium dioxide in Food and Nutraceutical products creates a huge challenge for the industry and raises wider concerns over its potential extension to the pharmaceutical sector. With thousands of pharmaceutical products currently using titanium dioxide in tablet or capsule coatings, the reformulation race is on to identify suitable alternatives.

Knowledge Base

Dawn Philips

Recent Posts

Overcoming Consistency Challenges in the Iron Making Sector

Caleva's International Sales Manager Steve Mate visited the Department of Chemical Engineering at Osaka Metropolitan University to find out how the Mixer Torque Rheometer (MTR) is being used.

Exciting Development for the Future of Oral Dose Drug Delivery

Investigating drug dissolution enhancement and controlled release of solid-liquid hybrid dosage form using Liqui-Pellet technology.

Discover how the Caleva Multi Lab was used to demonstrate the flexibility and potential of Liqui-Pellets as the next generation oral dosage form.

Caring for Your Lab Machines: The Importance of Regular Machine Maintenance

To meet GCLP requirements in research and development it is essential that your lab machines are functioning at the required standard, providing accurate, reliable, and repeatable results.

5 Reasons Why You Should Choose Caleva

At Caleva we want to help pioneering research and formulation scientists achieve results and we believe that our range of R&D machines should make achieving these results as easy as possible.

Do I Need a Screen Extruder or a Screw Extruder?

At Caleva, we offer a variety of extruders to meet your needs, from laboratory scale extruders for research and development purposes, to pilot scale extruders and larger models for batch production environments.

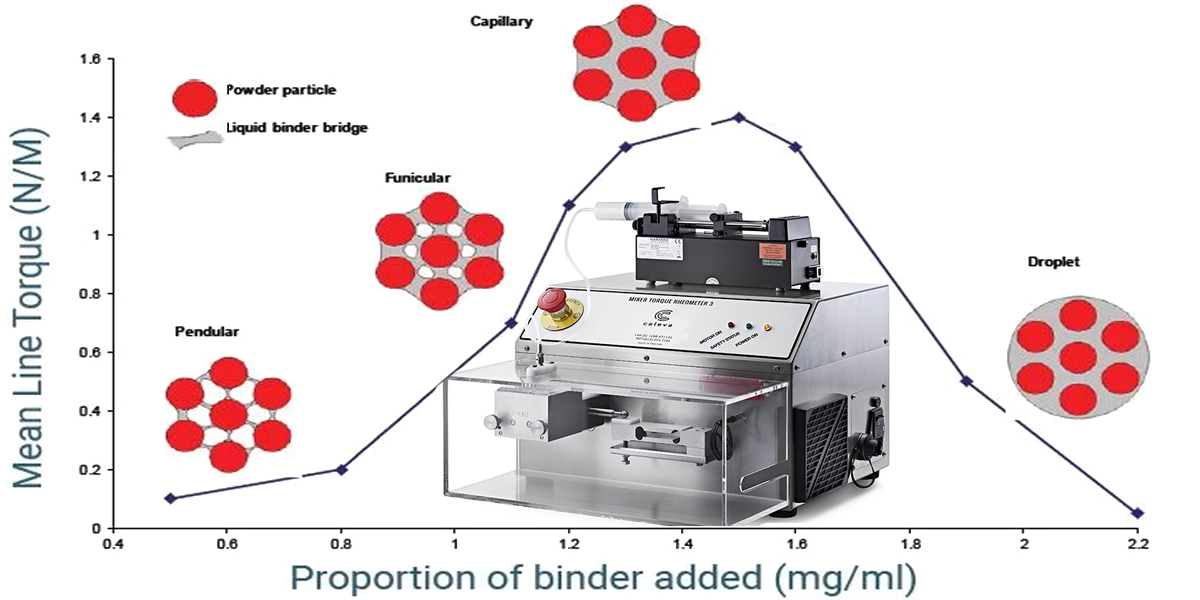

Measuring and monitoring your formulation

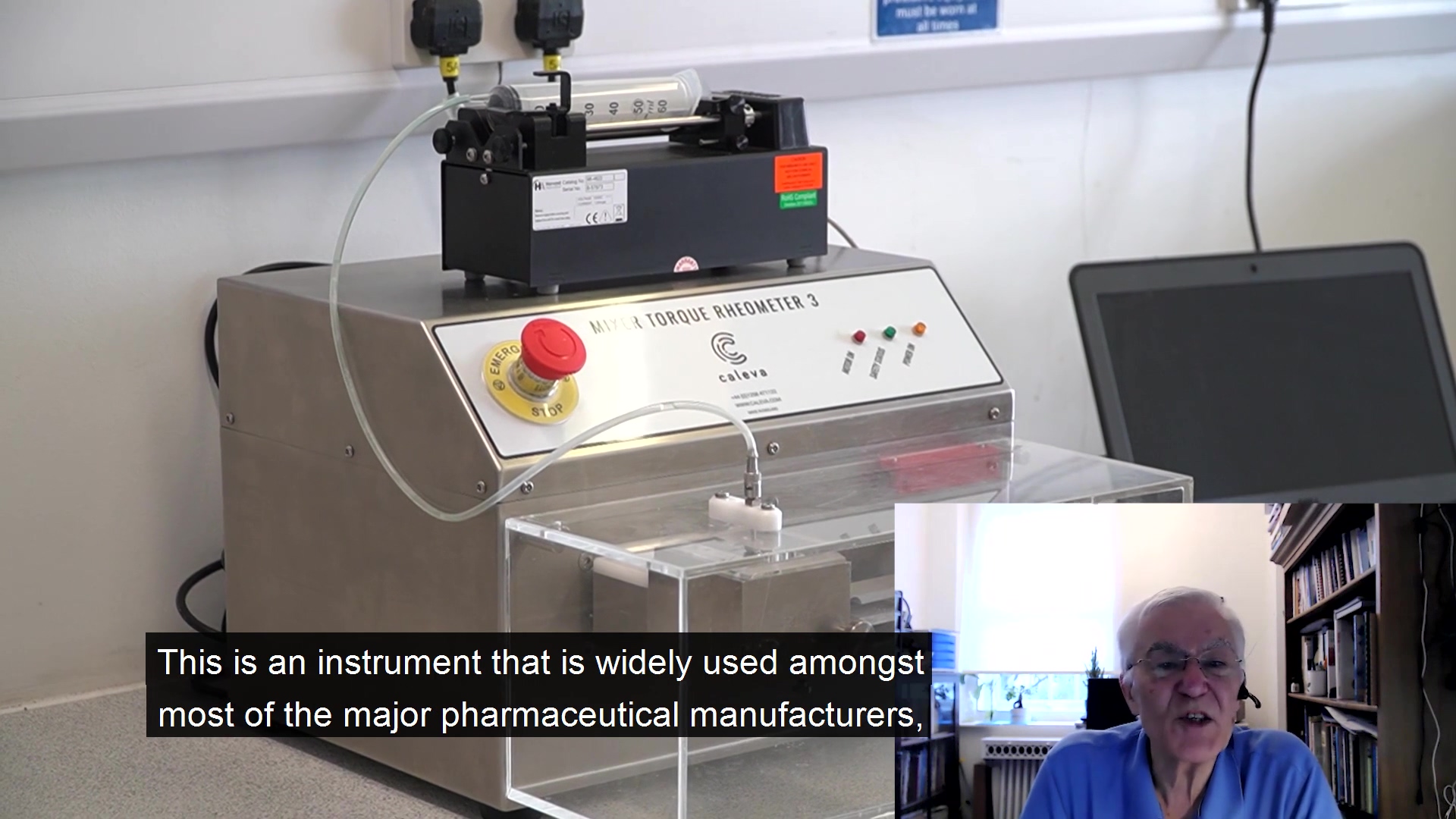

Did you know that the Mixer Torque Rheometer (MTR) is designed to carry out 3 separate experiments essential to your formulation development and production?

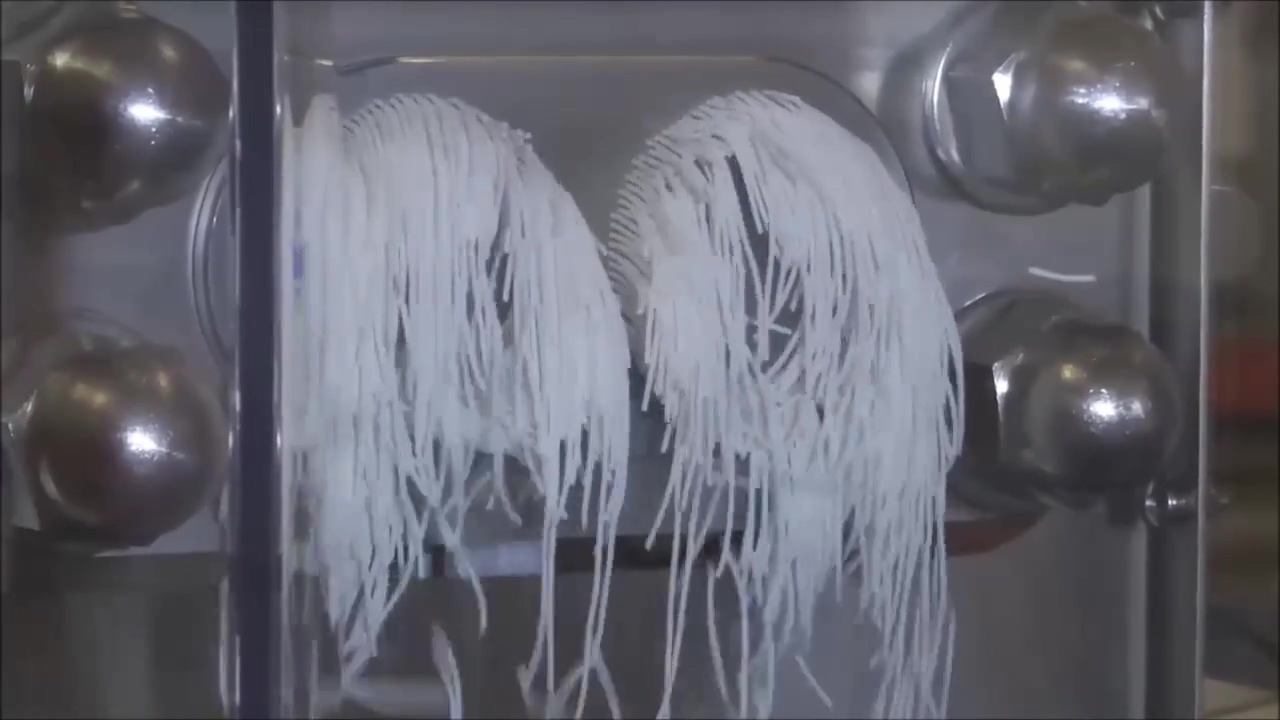

Equipment for the manufacture of pellets

Switch quickly between different materials with this easy to clean CE marked, top quality extrusion and spheronization system. An example of reliable and efficient British engineering at its best - this is the best option for your pellet production and is backed by the highly acclaimed support from Caleva Process Solutions.The Caleva system gives you the ability to vary the density of the...

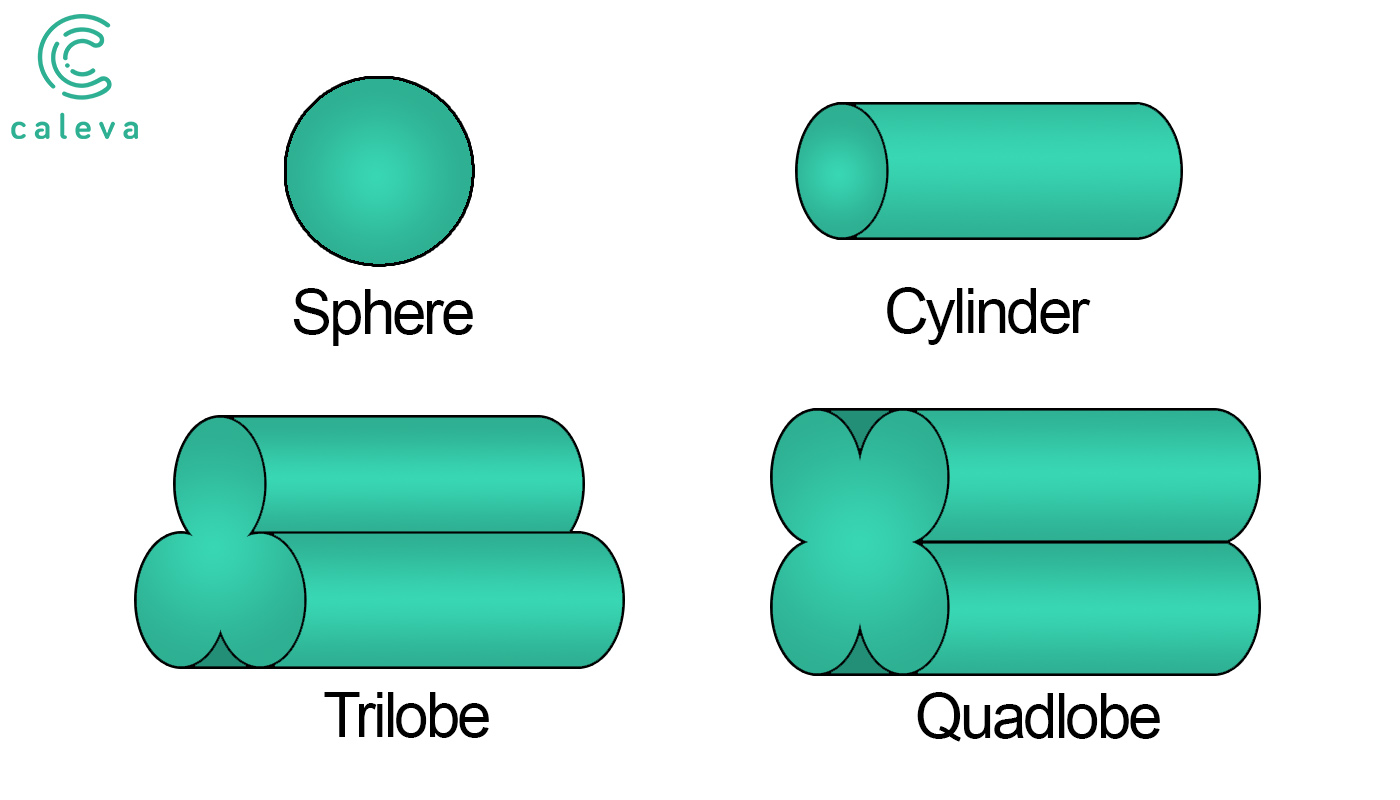

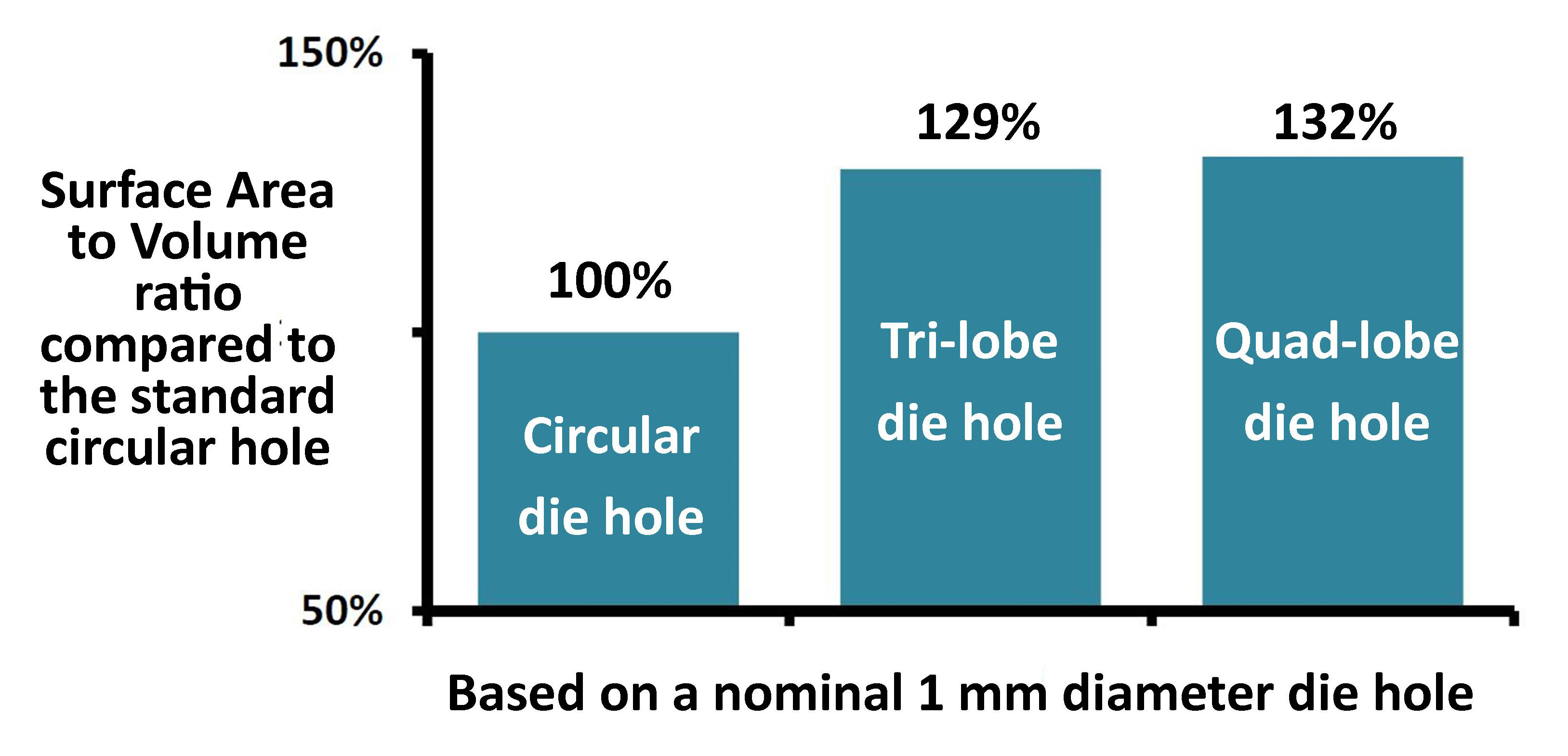

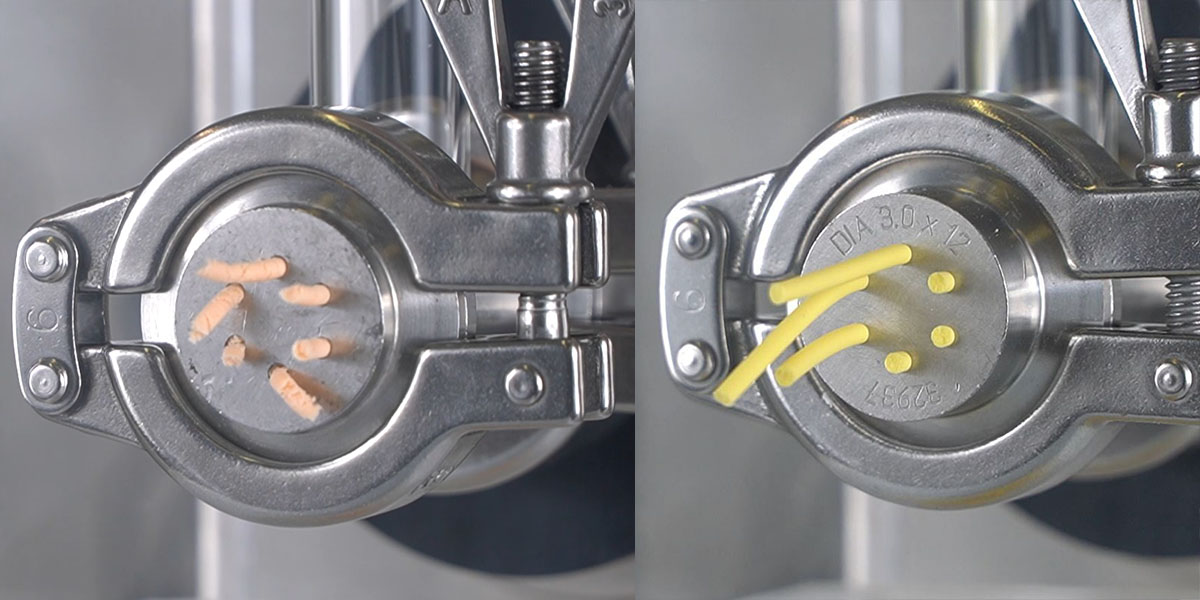

Increase Surface Area of your product with Trilobe and Quadrilobe Dies

An opportunity to shape and form catalyst materials/particles

Caleva have had some considerable success with working with the extrusion of small quantities of catalytic material using the Multi Lab series. (the first steps of blending and mixing can also be completed in the same Multi Lab base machine)

Caleva Study on the Importance of Granulation

Our customer, a major pharmaceutical, biotech & nutraceutical manufacturer with an extensive portfolio of products. For reasons of confidentiality we do not name them.

One of our Production Extruder & Spheronizer Systems for manufacturing on a large-scale was used in trials by the manufacturer, but the pellets produced were not acceptable. As the product was already registered, the composition...

An Introduction To Extrusion and Spheronization

Download a PDF version of this guide at the bottom of the page

What is Spheronization?

Spheronization (sometimes referred to as Marumerization) is the process where extrudates (the output from an extruder) are shaped into small rounded or spherical pellets (spheroids, beadlets). The pellets usually vary in size from 0.4 to 3.0 mm. Pellets can be used in a wide variety of industries.

Why...

Caleva explain the basic Mixer Torque Rheometer concepts - Video

The MTR can process from 10g to 25 g of your material, depending on the formulation, meaning barely any material is wasted in experiments. The machine will very quickly tell you the ideal amount of liquid to add. The user may have a start point in mind but this may result in a formulation that is too wet or too dry. The iterations may be repeated, but this can be wasteful in terms of materials...

A Tool for Pre-Formulation Assessment of Excipients

Excipients from different batches or vendors may vary in quality and it is often necessary to perform pre-formulation assessment for each new batch of excipient received.

Extruding catalyst materials for petrochemical and adsorption products

Using the Caleva Multi Lab it is possible to extrude of small quantities of catalytic material, whilst increasing the surface area to volume ratio of the extrudate produced.

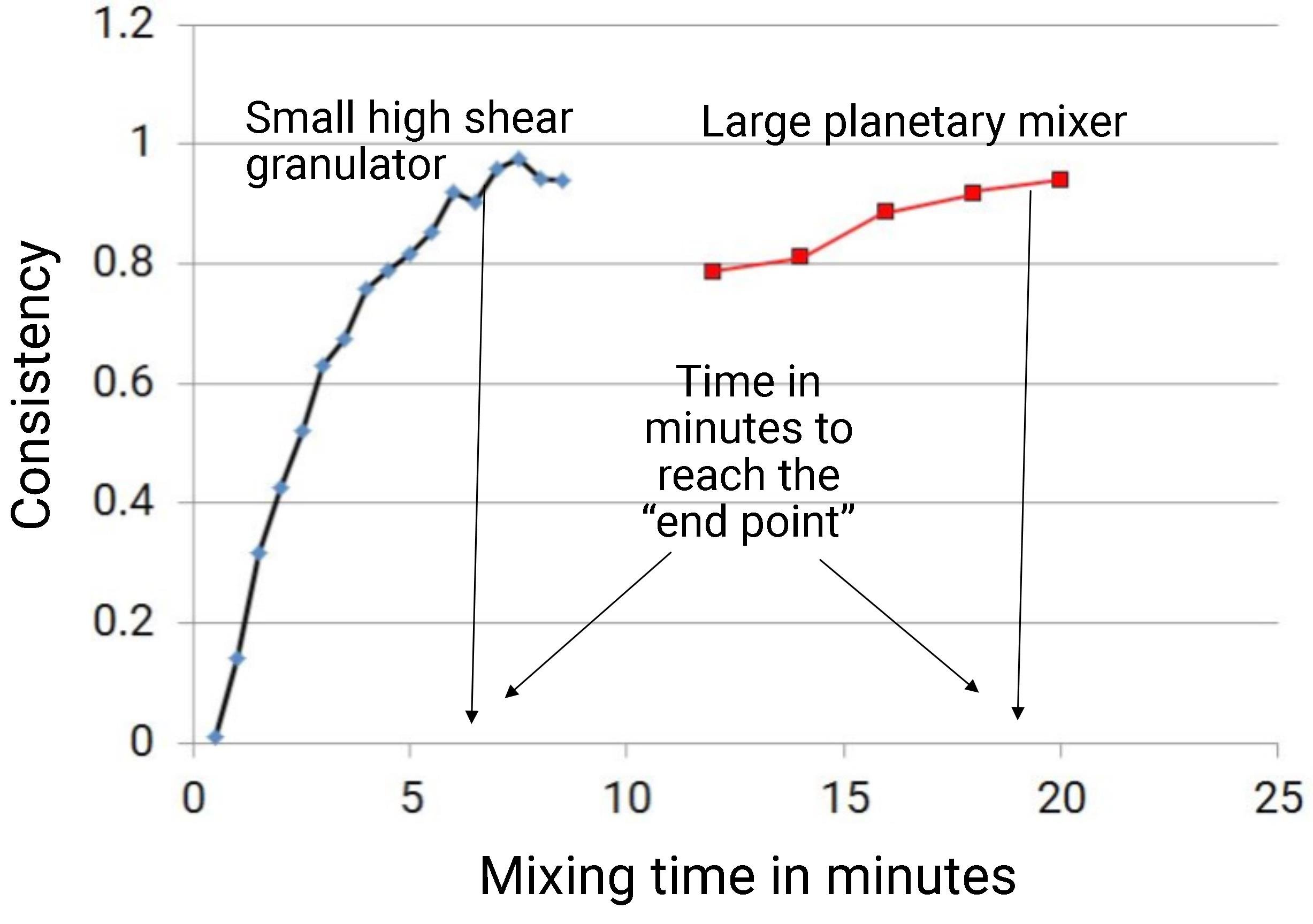

How Do You Ensure Consistency During Scale Up?

The Mixer Torque Rheometer's Consistency Test

To ensure consistency is maintained during scale up and production, the Mixer Torque Rheometer can be used to perform a quick and simple test which monitors the consistency of the wet granulation during the mixing phase. This test can be used whether you are working with continuous or batch production.

What type of pharmaceutical or catalyst extruder do I need?

All extrusion processes require the generation of pressure within the material to be extruded. When materials are put under pressure heat is generated. This cannot be avoided but different extrusion types generate different amounts of heat. There are basically three different types of extruder and the one chosen may have far reaching implications on production operations. It is important that the...

What pharmaceutical products or drugs can I make in pellet form?

View a list of suggested uses for pellets in pharmaceutical applications.

What characteristics should my extrudate have?

Extrusion and spheronization is not always completely straightforward. A formulation required for spheronization needs to go through the following processes and achieve the following properties.

Should I use spheronization or layering to manufacture pellets?

There are two main ways to make small pellets for drug delivery:

- Drug layering onto inert starter (or seed) pellets that are bought commercially

- Extrusion and spheronization binding the active material in the substrate of the pellet from the beginning

There is no right or wrong way to make pellets. The most appropriate method for your particular application will depend on what you are trying to...

Rheology methods for the formulation development of tablets

At Caleva we are known for our expertise in helping our customers in the pharmaceutical industry with extrusion, spheronization, and making pellets.But we can also help with tabletting projects !The Caleva Mixer Torque Rheometer (MTR) is widely used to measure the characteristics of a wet granulation to establish the correct endpoint and mix time for any given formulation.The experiments and...