Customer Quote: Mr. K.S (Aurobindo)

"It is exciting to see the correlation between the two graphs and granulation end point".

With a major pharmaceutical manufacturer, together we characterised all their various mixers to produce a consistent formulation.

To identify three important characteristics for wet mass materials, namely:

- The Optimum moisture point

- The mixing time required to reach the Optimum moisture point

- Identify the consistency point of the wet mass and calibrate each mixer differently.

Each experiment was run multiple times to gain the advantage of averaging, making the results Valuable.

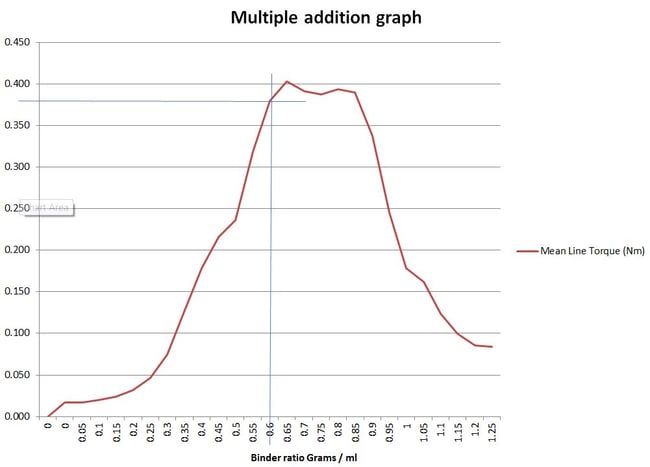

Multiple addition graph

This was setup to add 1ml of water to 30grams of placebo blend every 1 minute

The MTR will initially measure the torque response of an “Empty bowl” this is to remove noise from the final result to ensure the torque result of the placebo blend and accurately reflect the torque response of the blend itself.

Next add the 20 grams of the material blend to the bowl

The MTR will now measure the torque response of the dry mix for 30 seconds. After 1 minute, 1ml of water will be added automatically via the binder addition pump, mixed for 30 seconds and the data logged for 30 seconds. This will continue until the end of the steps. The number of steps in this instance was 35, more than enough to ensure we have a full and complete curve.

This experiment was conducted 3 times.

If you now review the Multiple addition graph attached, you can see I have chosen a point on the curve that is just within the capillary stage. This represents the optimum point for the manufacture of tablets and extrudate for the spheronization process.

With this knowledge we can determine that the torque response at this point is 0.375Nm and the moisture level / binder ratio is 0.6ml / gram

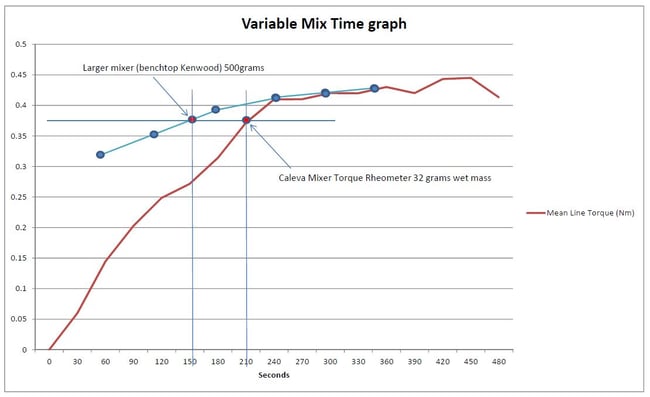

Variable Mix Time Graph

As we are using 20 grams of material and we now have an ideal binder ration of 0.6 ml/gram, we can move onto understanding how long it will take to reach the 0.375N/m torque response.

Using the Caleva MTR “Variable Mix Time” parameter, we add ALL the water at the start of the mixing session and record how long it will take to reach the optimum torque response 0.375N/m. We first calculate the correct binder addition required (20gram sample x 0.6ml/mg = 12.2ml of water)

This experiment was conducted 4 times.

On reviewing the the “Variable mix time graph” it can be seen that the red line represents the torque response over time and that it reached the 0.375N/m point at 210 seconds.

![]()

We now know that in the Caleva Mixer Torque Rheometer, we can achieve a wet mass consistency that will produce your desired result since we know that it takes 210 seconds with 12.2ml water added to 20 grams of material.

Consistency Parameter

This experiment is designed to take samples (32grams) from a benchtop mixer (Kenwood) at 1 minute intervals and run a short consistency test that will show the torque measurement of that wet mass consistency (for best results you should remove 3 samples from 3 different areas of the mixture to obtain an average torque value). Record this measurement and time and continue to run the mixer for another minute. Continue until the torque level required has been reached. This will then identify the time it will take to reach the same torque level to identify the correct moisture content for the wet mass.

If you now review the “Variable mix time” (below) graph the blue line represent the larger mixer with 500 grams of dry placebo blend. Knowing that we need to have a binder ration of 0.6ml/gram (500grams x 0.6 ml/gram = 300ml of water) using a stop watch start the mixer add all the water at the beginning and then stop the mixer and remove 32gram samples for evaluation in the MTR “consistency” testing parameter. The result are then logged on the Variable mix time graph.

Conclusion:

We can now see that the larger mixer is able to reach the desired moisture point in 160 seconds, concluding that to mix 500 grams of material in the larger mixer with a binder addition of 300 ml and mixed for 160 seconds will produce the desired moisture state of the wet mix.

This gives us a brief insight into some of the experiments that the MTR instrument can be used for and how a decision can be made on how to optimise a formulation. It is important to be accurate and consistent in recording and of the parameters used. This consistency and accuracy of approach will give meaningful data upon which to make accurate decisions.

I am confident that this instrument will provide great benefit and give you accurate data so that you can make decisions about your formulation confidently.

Leave A Comment