The Mixer Torque Rheometer can be used to assess the behaviour of excipients purchased from different suppliers.

Background

Excipients from different batches or vendors may be variable in quality and it is often necessary to perform pre-formulation assessment for each batch of excipient received. In some cases, excipients from different vendors require comparative assessment of their equivalent functionality. In this type of assessment, the Mixer Torque Rheometer can be an invaluable tool to evaluate the potential performance of the excipients received, in particular for spheronization aids.

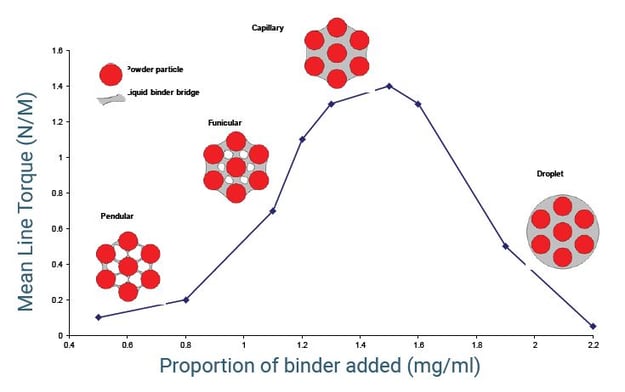

Fig 1. Example of MTR curve showing the relation between the mean torque of wet mass with moistening liquid addition and four phases of liquid-solid interactions

Introduction

Pellets are commonly produced by extrusion and spheronization. Microcrystalline cellulose (MCC) and cross-linked polyvinyl pyrrolidone (XPVP) have been reported to be very good spheronization aids [1]. For the two excipients, many brands and grades are available commercially. Different companies often use raw materials from different sources and employ different processing techniques or conditions to manufacture their excipients. Even with the same process and raw materials, batch to batch variability will exist. Therefore, variabilities in different grades and batches of the same excipient are unavoidable.

The MTR can be a useful pre--formulation tool to characterize excipients, in particular spheronization aids and classify them into several groups according to their performance in pellet production . For the extrusion-spheronization process, the addition of water to a powder mixture to produce a wet mass is required so as to produce a powder mass that is sufficiently cohesive. The MTR can be used to characterize this cohesiveness by determining the rheological behaviour of wet mass [2].

As the MTR involves adding liquid to the powder blend and mixing them using rotating blades, the cohesiveness of powder blend will be related to the resistance on the mixing blades and the resulting torque is measured and recorded. Torque values are used to quantitatively describe this cohesiveness. On the basis of this principle, a curve showing the relationship between mean torque and liquid addition can be generated. Another parameter, cumulative energy of mixing, which describes the total energy input, has also been used to assess the effect of MCC grade variations on the cohesiveness and rheological behaviour of wet mass .

Case Study 1

Soh et al. evaluated eleven different grades of MCC, collected from different excipients companies in their study [3]. Lactose was also used in the study as MCC-lactose blends are commonly used to produce pellets. Maximum torque of MCC [Torquemax(MCC)], maximum torque of blend [Torquemax(blend)], cumulative energy of mixing of MCC [CEM(MCC)] and cumulative energy of mixing of blends [CEM(blend)] were measured. Water content used ranged from 75 % - 175 % (w/w) for MCC and 25 – 55 % (w/w) for blends. Pellets were produced using 3:7 blends of MCC:lactose and 25, 30, 35, 40 and 45 % (w/w) water.

Measured rheological properties (torque parameters) were further correlated with MCC grades and their respective pellets.

The study was essential to understand the characteristics of MCC particles considering their liquid saturation. For example, at lower used water amounts, less porous, denser and more crystalline MCCs resulted in larger torques and thus, more energy was required for mixing. Also, good correlations were found between the rheological properties of MCCs and MCC:lactose blends with the properties of produced pellets, particularly those produced at 30 and 35 % (w/w) water.

Mixer Torque Rheometer bowl and blades

It was easily identified that the physical properties of pellets prepared by MCC:lactose blends could be compared with the rheological properties of MCC grades and it was not necessary to characterize binary mixture. Thus, without the need to prepare MCC:lactose blend for rheological characterization, analysis time could be saved in pre-formulation analysis stage. It was further identified that the rheological properties characterized by the MTR can depict the MCC grade more comprehensively than any single physical characterization parameter of MCC.

The study proved that the MTR can be a powerful preformulation tool to characterize spheronization aids and predict the properties of pellets to be manufactured by extrusion-spheronization.

Case Study 2

Another study, characterizing different MCC grades using MTR further confirmed its suitability as a pre-formulation tool [4]. Rheological properties of different MCC grades were studied and the mean torque value was used for comparison of different MCC grades. Two standard grades of MCC having similar particle size distribution were obtained from two different sources and compared.

Mostly, the mean torque values were lower for the MCC obtained from one source than the MCC obtained from another source. These differences in the mean torque values suggest potential differences in the MCC-water interactions, which could impact the final pellet product quality. Thus, the performance of MCC obtained from different sources could be evaluated based on the rheological characterisation using a Mixer Torque Rheometer.

CONCLUSIONS

- Cumulative energy of mixing, a torque parameter measured by Mixer Torque Rheometer classified excipients into groups by their predicted performance.

- The quality of the pellets produced using different grades of MCC could be predicted using the measured torque values.

- Mean torque value proved to be another important parameter to assess the functionalities and performance of spheronization aids.

REFERENCES

[1] Sarkar S, Heng PWS, Liew CV. Insights into the functionality of pelletization aid in pelletization by extrusion-spheronization. Pharm Dev Technol 2013; 18(1): 61-72.

[2] Hancock BC, York P, Rowe RC, et al. Characterization of wet masses using a mixer torque rheometer: 1. Effect of instrument geometry. Int J Pharm 1991; 76(3): 239-45.

[3] Soh JLP, Liew CV, Heng PWS. Torque rheological parameters to predict pellet quality in extrusion-spheronization. Int J Pharm 2006; 315(1-2): 99-109.

[4] Luukkonen P, Schæfer T, Hellén L, et al. Rheological characterization of microcrystalline cellulose and silicified microcrystalline cellulose wet masses using a mixer torque rheometer. Int J Pharm 1999; 188(2): 181-92.

Ver 00129

Leave A Comment