Discover how to cut your formulation development time in half with the Caleva Multi Lab and its wide range of variable density dies.

Knowledge Base

Do I Need a Screen Extruder or a Screw Extruder?

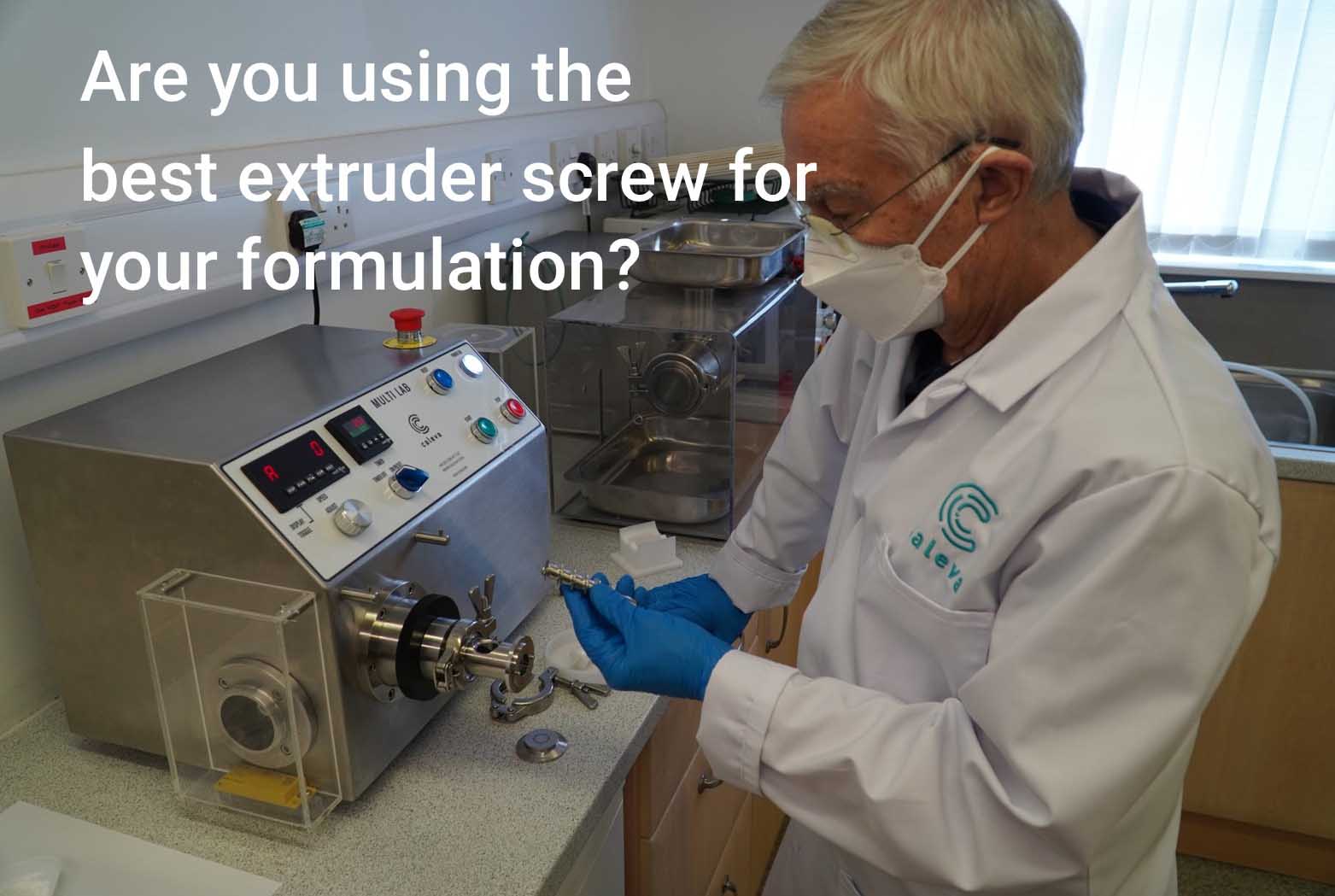

At Caleva, we offer a variety of extruders to meet your needs, from laboratory scale extruders for research and development purposes, to pilot scale extruders and larger models for batch production environments.

Extrusion of small batches

The Caleva Multi-Lab (CML) can Mix/Granulate, Extrude and Spheronize all in one base unit.

This article is about the Extruder attachment that comes with the CML.

The Multi-lab is capable of working with a variety of materials from catalysts and pharmaceuticals, to agricultural products.

The Extruder

The extrusion attachment on the CML is in the form of a single screw extruder. A variety of dies...

Possible issues with extrusion of small samples - how to resolve them

It is not possible to extrude and spheronize everything. Extrusion and spheronization can be used on a wide range of products and formulations. However, if you are having trouble extruding your formulations with the Caleva Multi Lab (CML) then please read this article.

Caleva offers extruder screws of different designs for use with the CML. If you are having issues with the CML then the first...

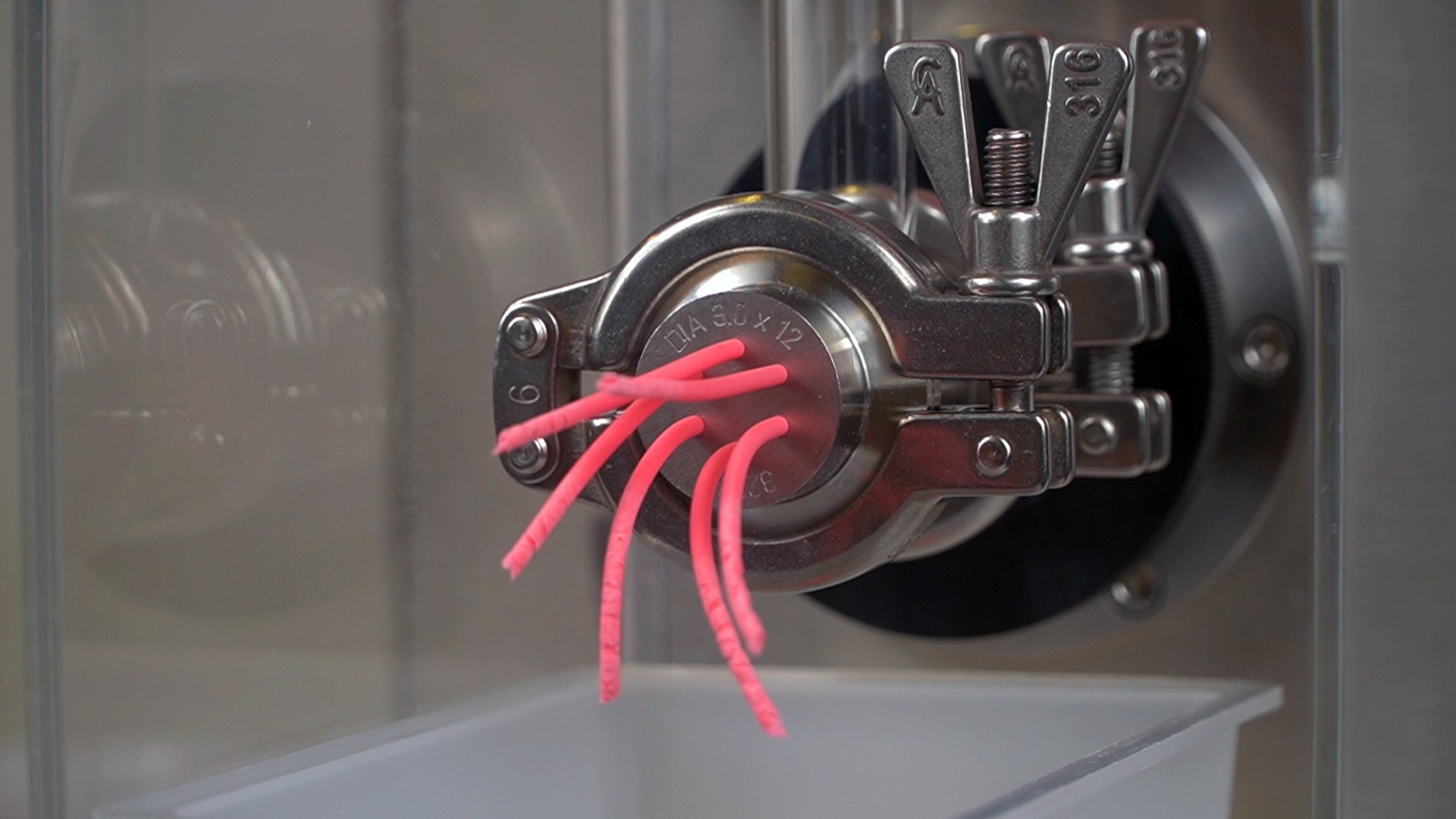

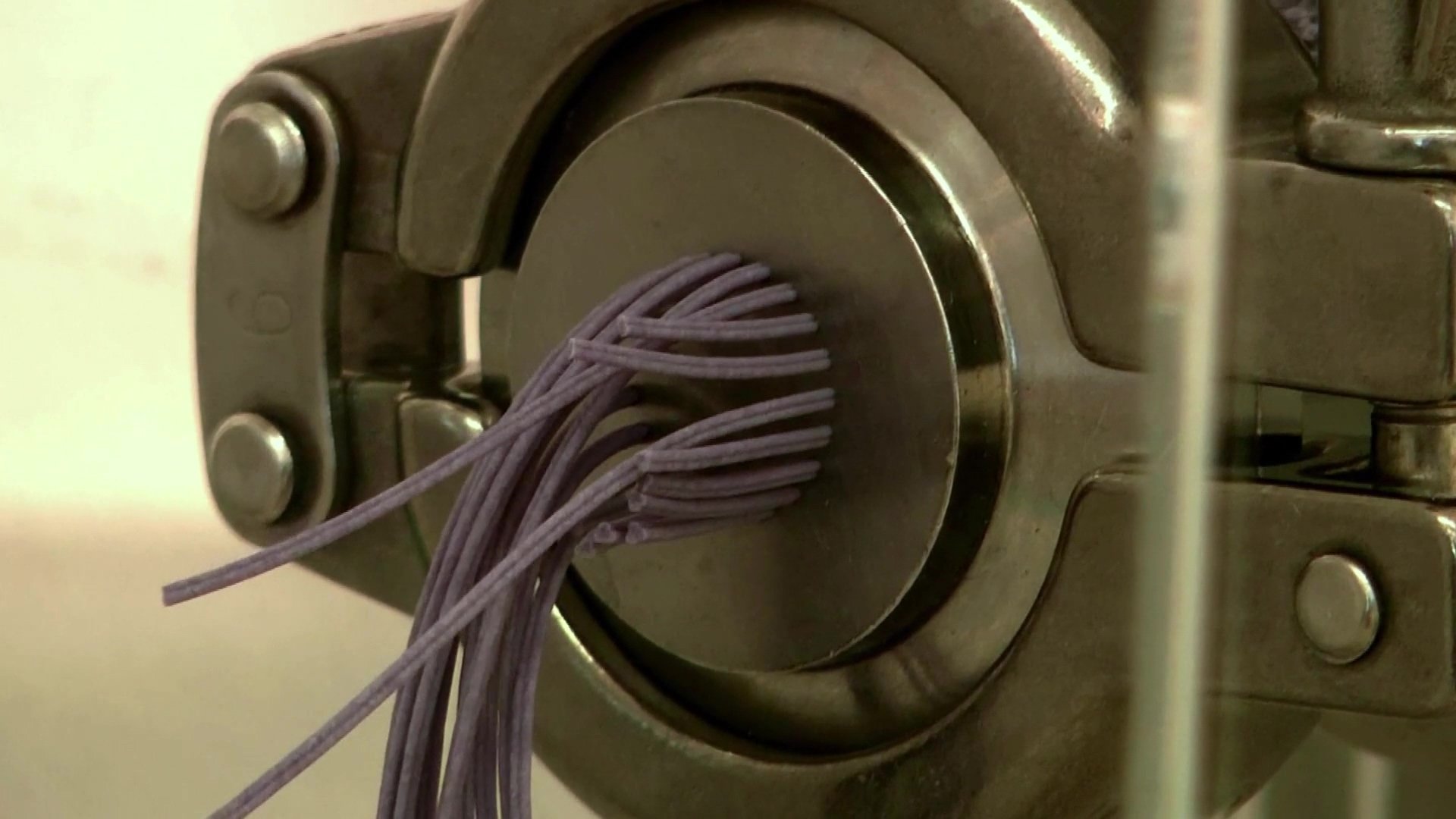

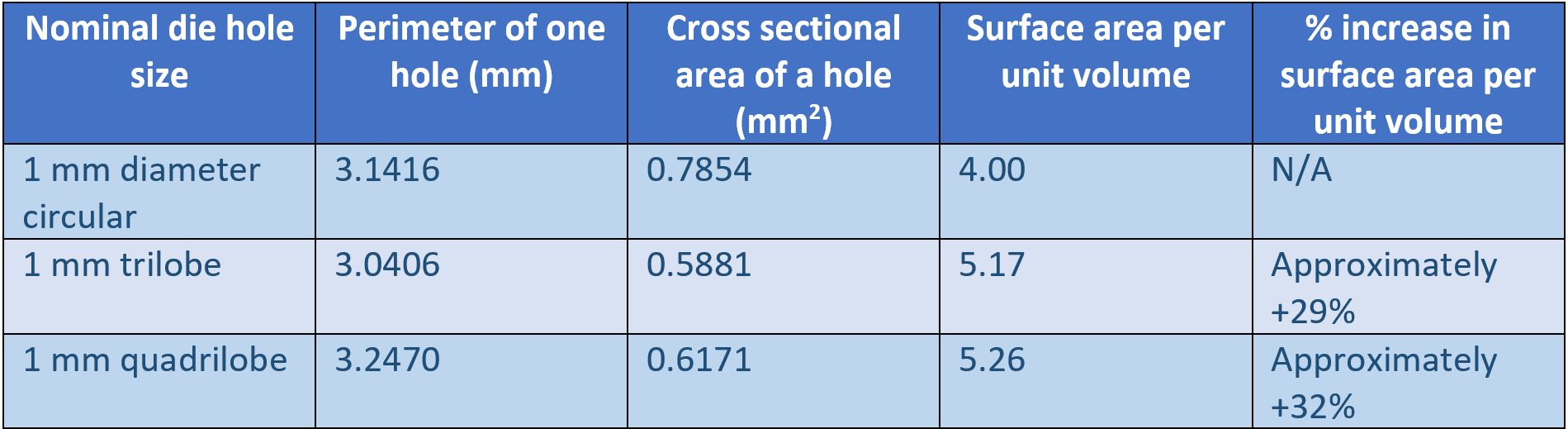

Extruder dies | all sizes | variable density | quadrilobe | trilobe

In the process of extrusion, having different dies available to process your product is key to increasing your chances of development success. This is why we offer a large range of dies to help you find the best options for your formulation.

We offer die plates that are excellent for most uses, like our 1 x 1 mm die, however sometimes a more specialist die may be needed. Our trilobe and...

Extrusion of catalyst and petrochemical materials

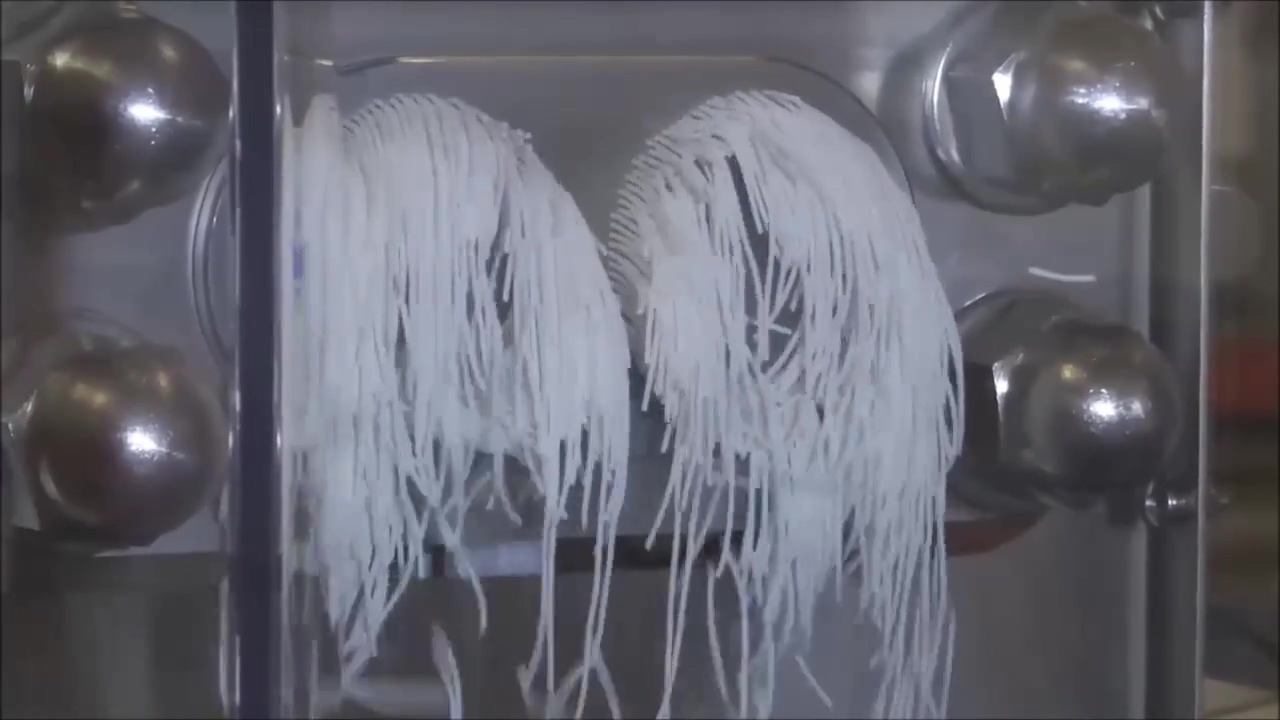

An opportunity in laboratory extrusion with catalyst material. We have recently had some considerable success with one of our customers working with the extrusion of small quantities of catalytic material.

Extruding catalyst materials for petrochemical and adsorption products

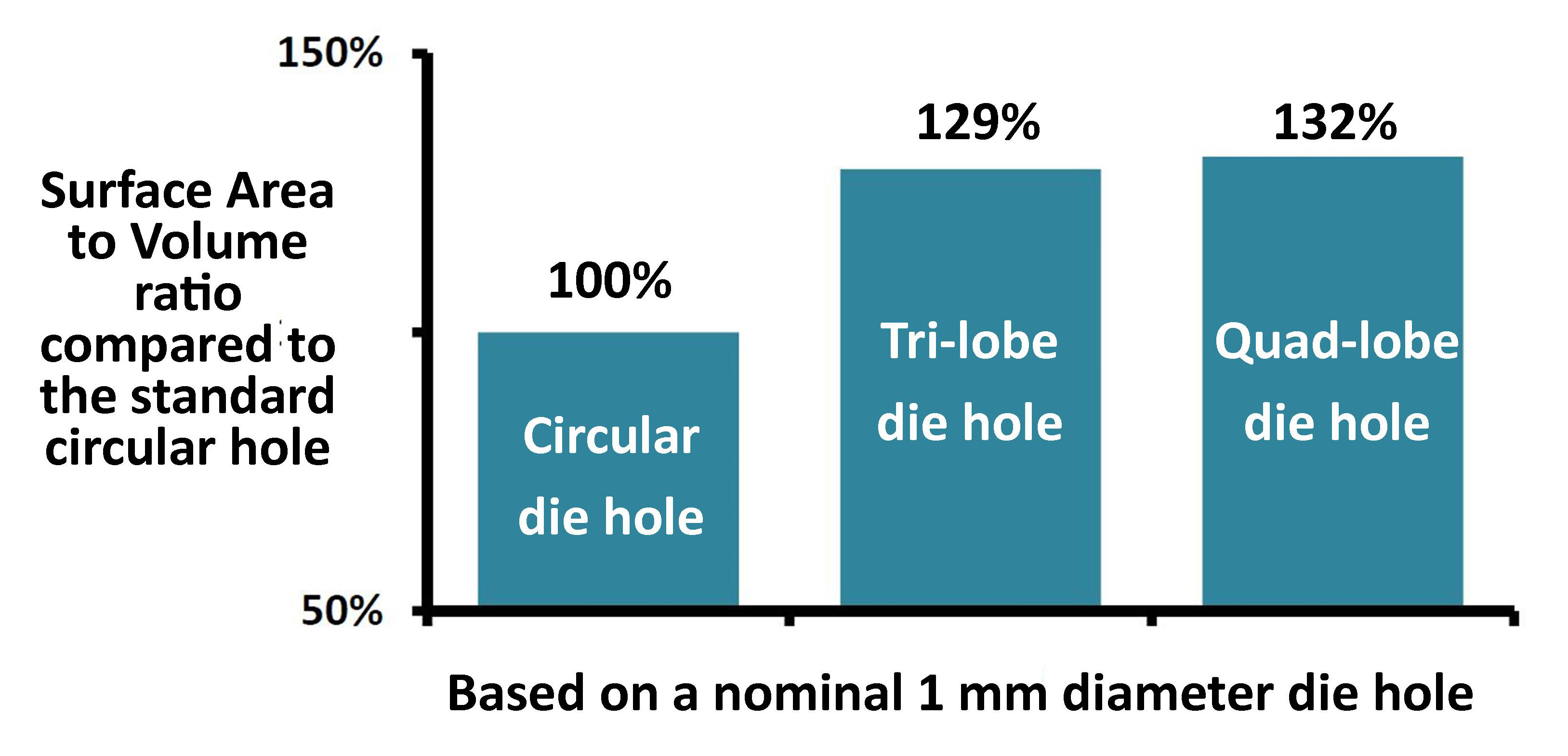

Using the Caleva Multi Lab it is possible to extrude of small quantities of catalytic material, whilst increasing the surface area to volume ratio of the extrudate produced.

Guide to the optimum diameter to length ratio of extrudate fragments

Is there a guide to the optimum Length to Diameter ratio of the extrudate fragments?

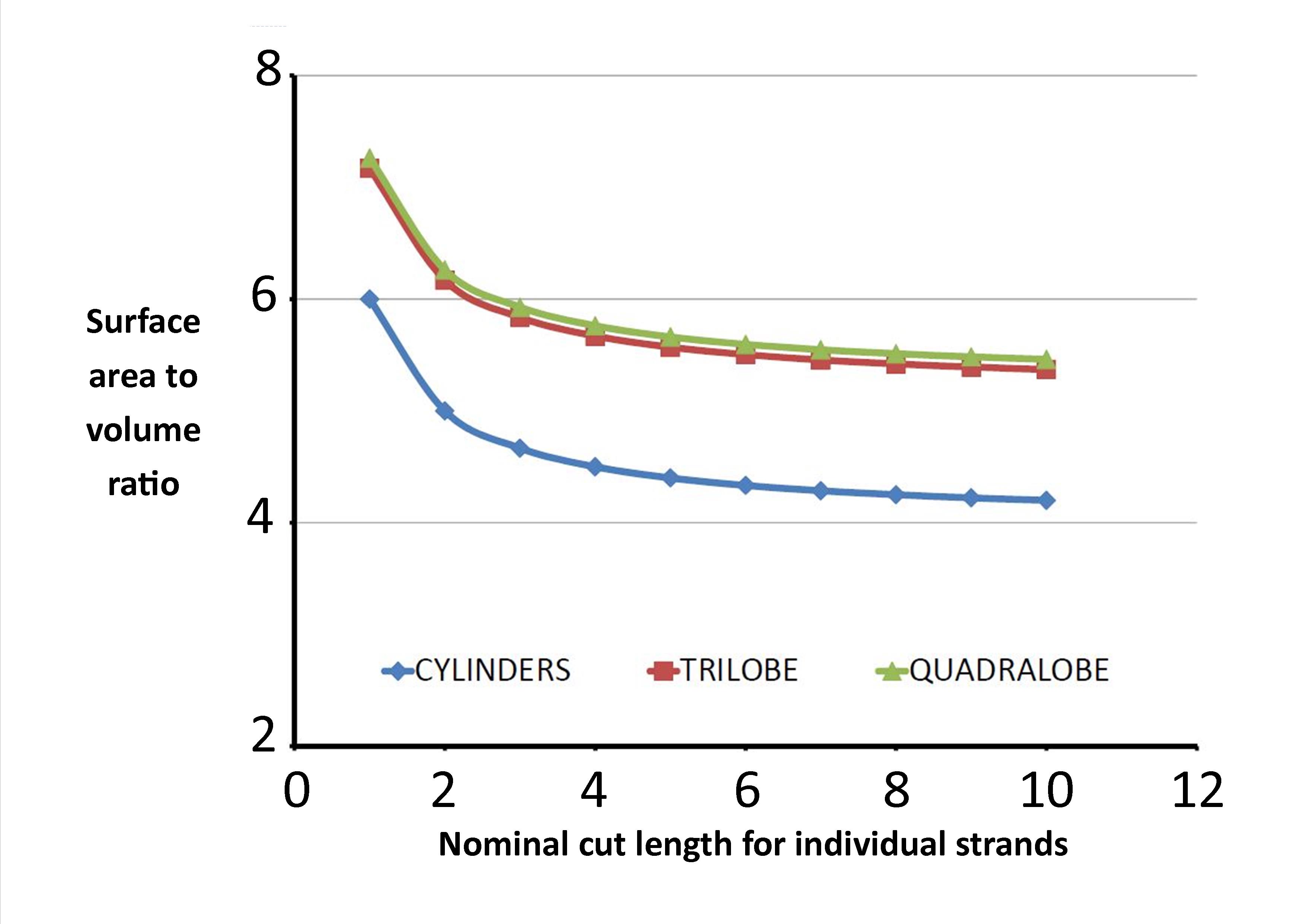

In the calculations used to demonstrate the data it is assumed that the extrudate is an infinitely long strand. In this case the length of the extrudate has no influence on the data shown. In reality, extrudate is not infinitely long and as the individual strands of the extrudate produced become shorter, the...

What type of pharmaceutical or catalyst extruder do I need?

All extrusion processes require the generation of pressure within the material to be extruded. When materials are put under pressure heat is generated. This cannot be avoided but different extrusion types generate different amounts of heat. There are basically three different types of extruder and the one chosen may have far reaching implications on production operations. It is important that the...

Increase the Surface Area to Volume Ratio in the Extruded Material

Can the equipment design help to increase the surface area to volume ratio (SA/V) in the extruded material (extrudate)?

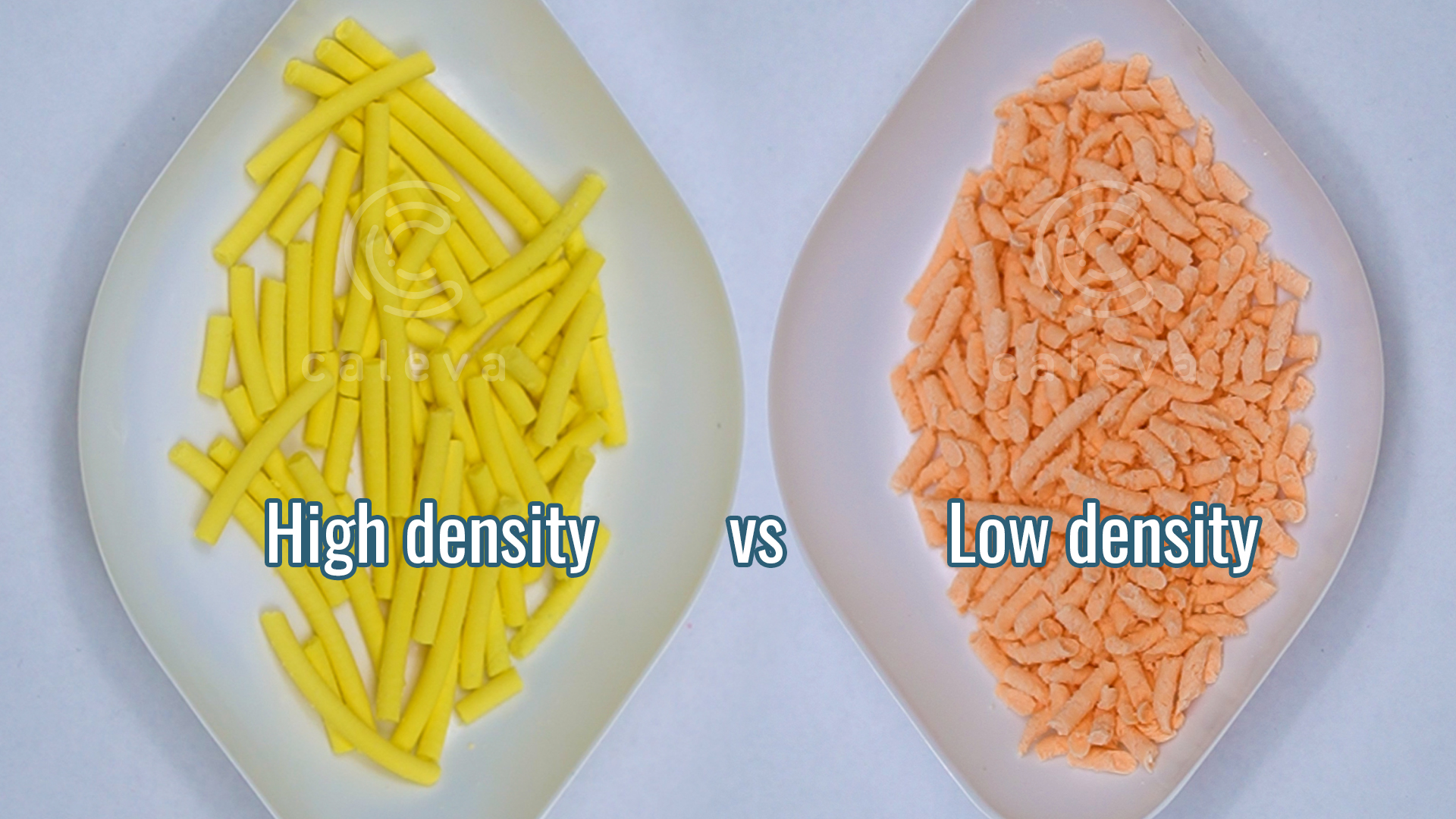

Modify the density, pore size and porosity of the extruded material

The Caleva CML extruder attachment is the smallest in the family of screw driven extruders that can offer the operator the ability to extrude the material at high, medium high, medium low, or low density. By management of the extrudate density physical properties of the extruded material can be influenced. The most important of these are likely to be:

Can I modify the density of extrudate produced during extrusion?

During the formulation development process, challenges related to final product performance have to be examined, exposed and overcome.

This is not always easy or straight-forward. However, if you have more options that you can investigate then there is likely to be an increased probability of a successful result. Different factors are considered as part of any formulation development and these...

Is there a correctly sized extruder die to get the size of pellets you need?

There is no simple answer to this question as it depends on the characteristics of your formulation and the size of the pellets you require.

How can I be sure that the trials and development work that I do will give me comparable results when I need to scale up to production sizes?

- The smallest extruder we offer is the Caleva Multi Lab (CML) with an extruder attachment designed to work with...