The rapid integration of artificial intelligence (AI) and machine learning (ML) into pharmaceutical research and manufacturing is reshaping how formulations are designed, tested, and optimized.

Knowledge Base

5 Reasons Why You Should Choose Caleva

At Caleva we want to help pioneering research and formulation scientists achieve results and we believe that our range of R&D machines should make achieving these results as easy as possible.

Equipment for the manufacture of pellets

Switch quickly between different materials with this easy to clean CE marked, top quality extrusion and spheronization system. An example of reliable and efficient British engineering at its best - this is the best option for your pellet production and is backed by the highly acclaimed support from Caleva Process Solutions.The Caleva system gives you the ability to vary the density of the...

Production Capacity Estimates for Extrusion and Spheronization Systems

We are often asked about the production capacity of our extrusion and spheronization systems. To provide this information there needs to be an understanding of the process parameters that will be used and that have been determined at the development stage. With that information, the advice that we give can be both meaningful and useful in the planning stages.If you have proven your concept at the...

How Do You Ensure Consistency During Scale Up?

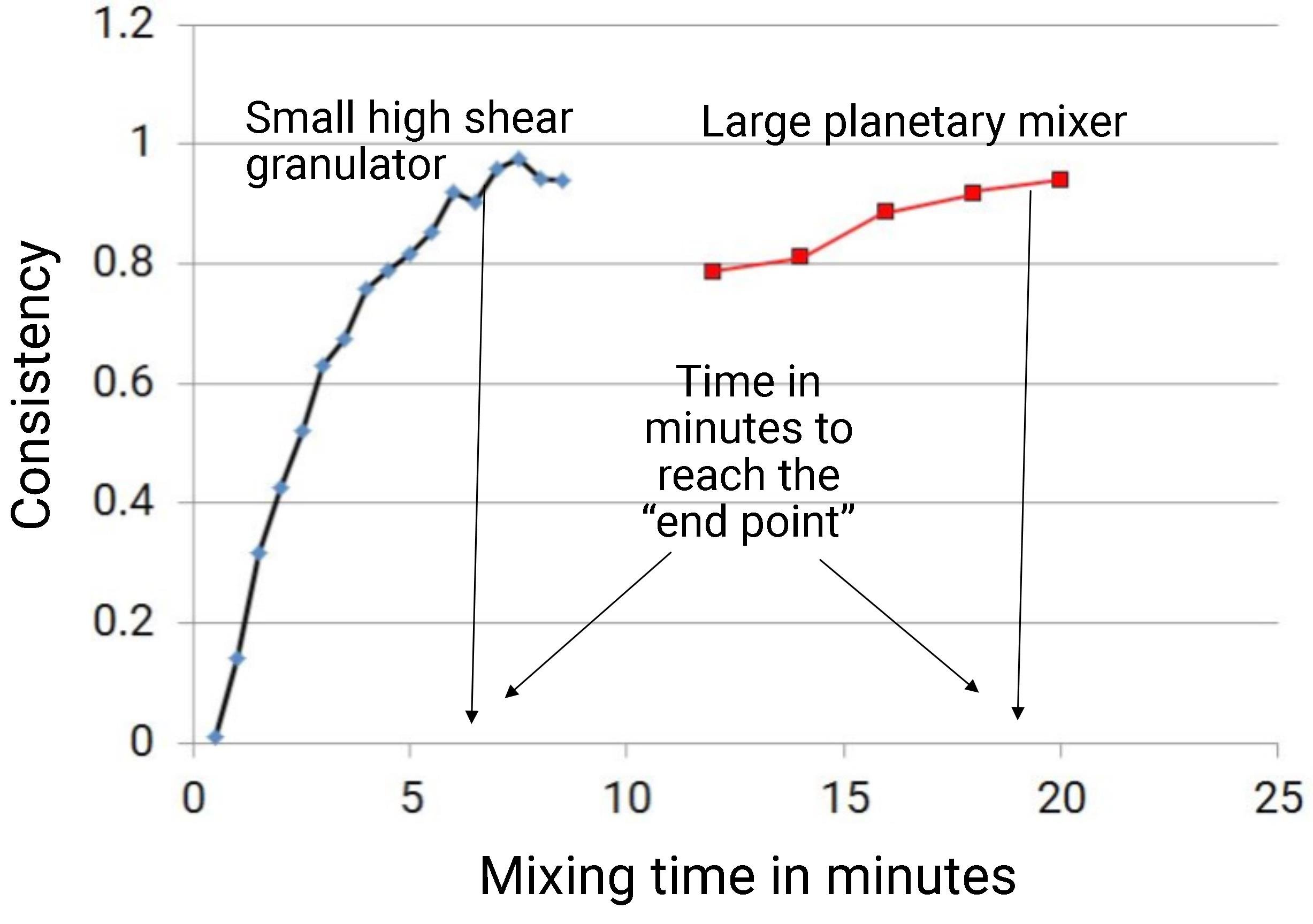

The Mixer Torque Rheometer's Consistency Test

To ensure consistency is maintained during scale up and production, the Mixer Torque Rheometer can be used to perform a quick and simple test which monitors the consistency of the wet granulation during the mixing phase. This test can be used whether you are working with continuous or batch production.

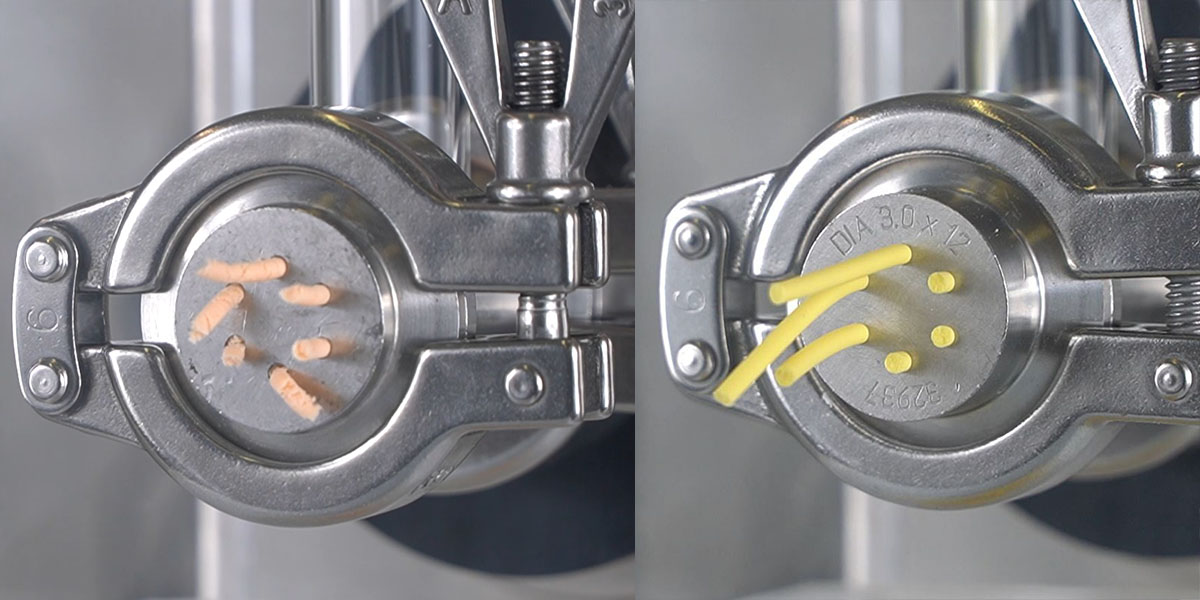

What characteristics should my extrudate have?

Extrusion and spheronization is not always completely straightforward. A formulation required for spheronization needs to go through the following processes and achieve the following properties.

What are the standard processes in the manufacture of pellets?

Wet Granulation - Granules are formed by the addition of a granulation liquid onto a bed of powder under the influence of an impeller. This is typically carried out using a high-shear granulator or a simpler planetary mixer.

Should I use spheronization or layering to manufacture pellets?

There are two main ways to make small pellets for drug delivery:

- Drug layering onto inert starter (or seed) pellets that are bought commercially

- Extrusion and spheronization binding the active material in the substrate of the pellet from the beginning

There is no right or wrong way to make pellets. The most appropriate method for your particular application will depend on what you are trying to...

Do all extruders and spheronizers have the same level of performance?

Product yields (the percentage of the spheroids produced in a batch that are within the size range required) will never be 100%.

Coating pellets and tablets - can results be used in scale up?

We are often asked if parameters used for film coating of materials in the Mini Coater Drier can be used for “scale up” to production. The desire for a process to be scalable is understandable but it is not always feasible or relevant.

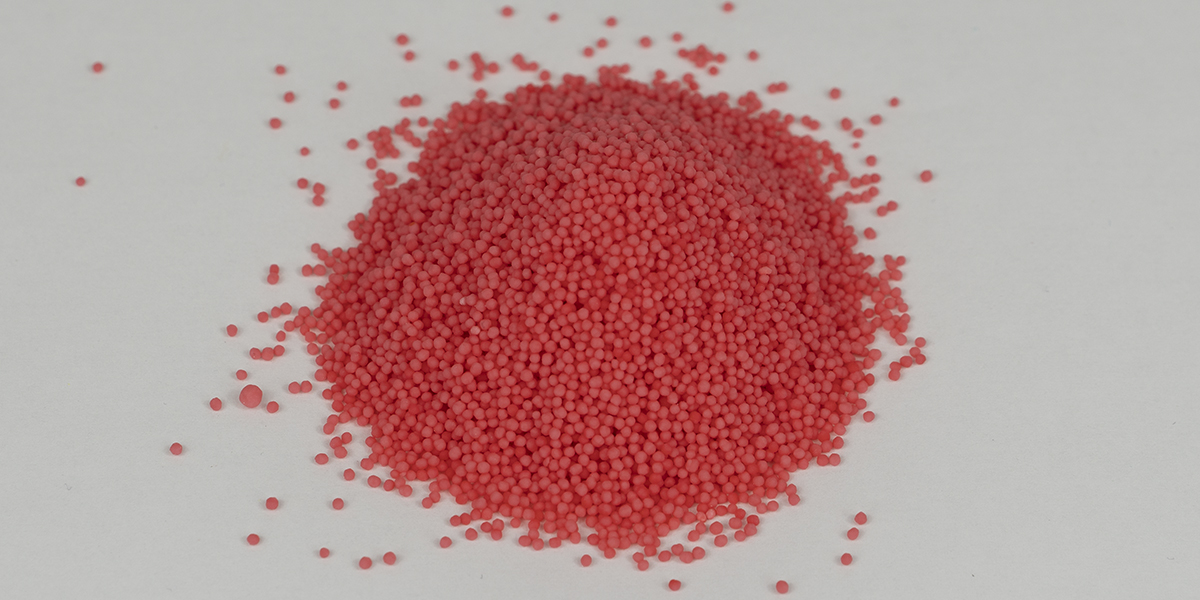

A better therapeutic effect with spheroids

In many cases the main reason for the use of pellets in the manufacture of products is for its controlled release properties. However there are reasons to believe that pellets or spheroids in any case can offer a superior therapeutic effect even when modified release is not the prime objective.

Examples of the terminology used in spheronization and marumerization

Spheronization, marumerization, pelletization and micropelletization all mean the same thing. The manufacture of products in small spheres (spheroids) for use in pharmaceutical (pharma) and catalyst industries. Within each batch the spheroids are of regular shape and size and are quite dense. The products produced by these processes can be called spheroids, spheres, micro-spheres, pellets,...

Extruding with the E35

The Caleva Extruder 35 is capable of processing batch sizes from 250g to 5kg (wet weight) of product to create an hourly output of approximately 100kg (product dependent).

The E35 works with a large range of materials, including pharmaceutical materials, catalysts and agricultural products.

The Extruder

The screen used for extrusion can be configured to your needs, with different diameter and...

Spheronizing with the S380

The Caleva Spheronizer 380 is capable of processing batch sizes from 250g to 5kg (wet weight) of product to create an hourly output of approximately 50kg.

The S380 works with a large range of materials, including pharmaceutical materials, catalysts and agricultural products.

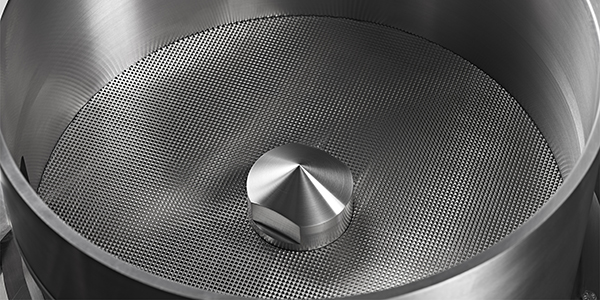

The Spheronizer

The spheronizer disc used in this example is the Caleva 3mm x 3mm cross hatch pattern which comes as...

How can I be sure that the trials and development work that I do will give me comparable results when I need to scale up to production sizes?

- The smallest extruder we offer is the Caleva Multi Lab (CML) with an extruder attachment designed to work with...

Do you have heat generation issues with your extrusion process?

During production scale extrusion heat is generated as a result of the process. The amount of heat generated will vary depending on:

- The formulation of the product

- The rate of extrusion

- The physical specifications of the extruder

- The type of extruder being used, for example, screw, gear, or basket.