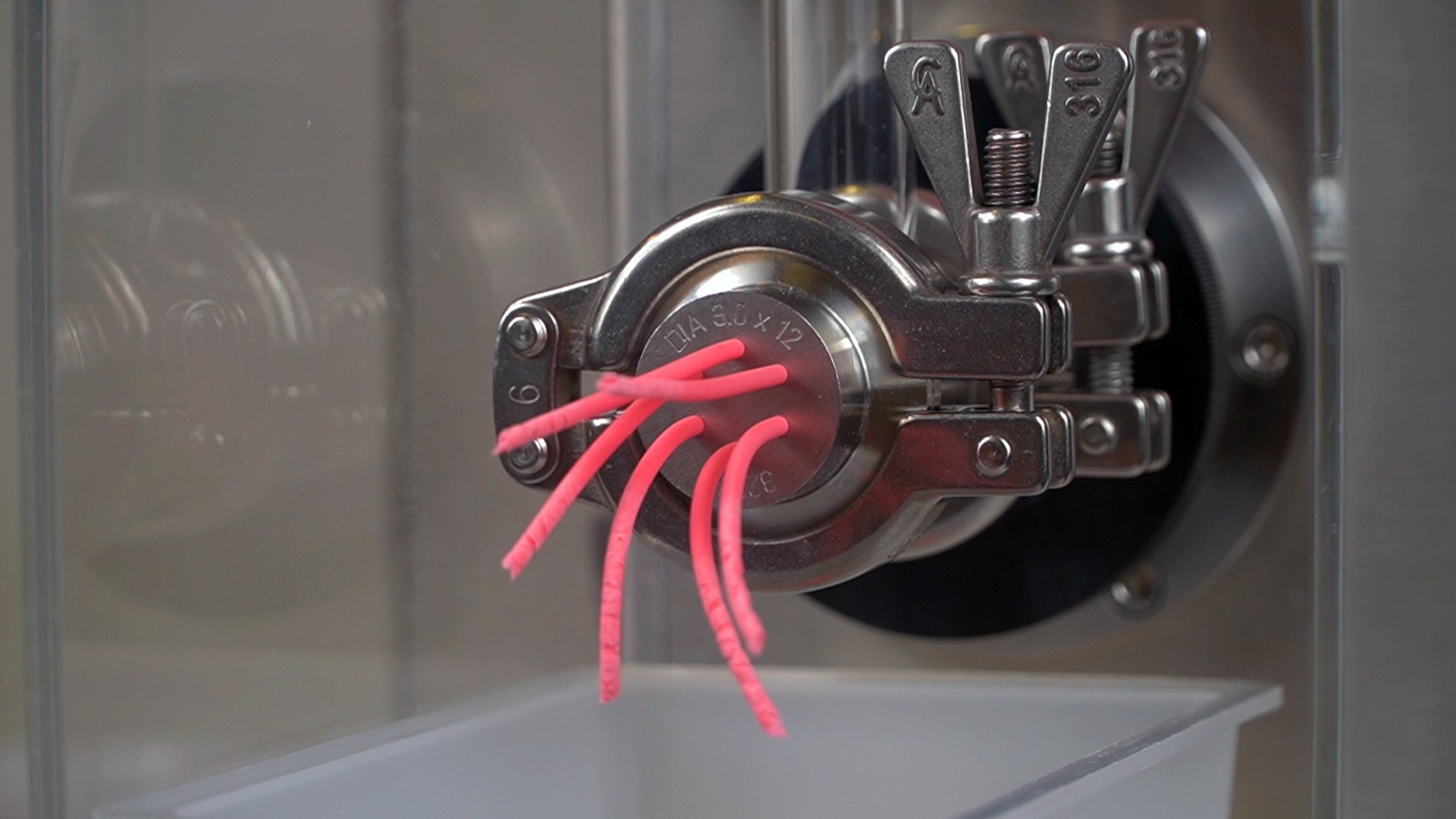

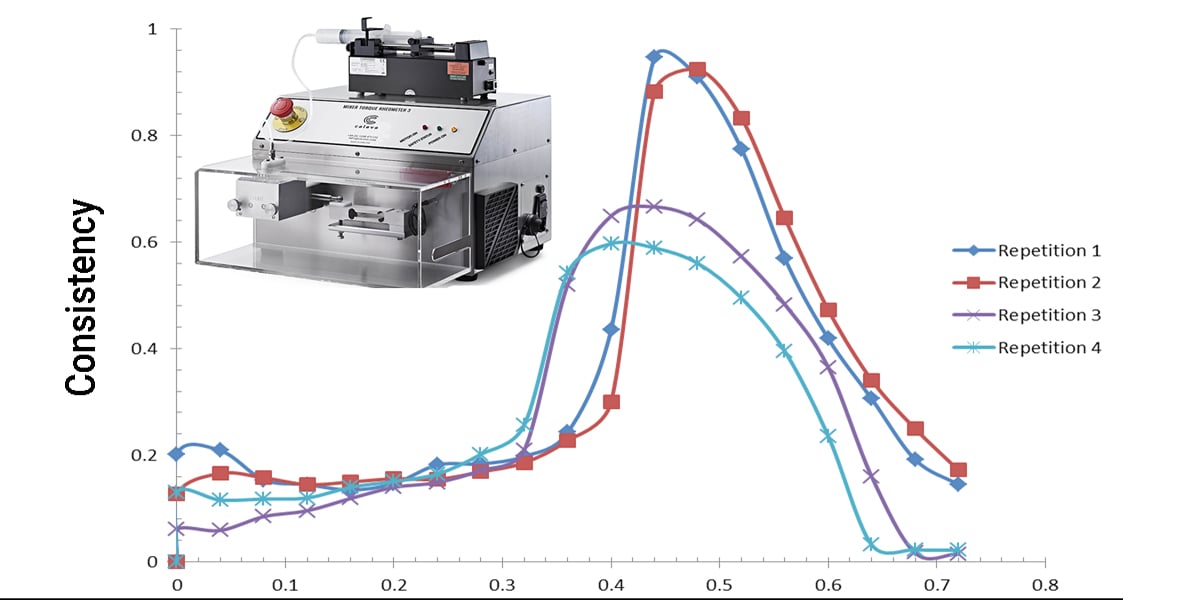

Are you interested in one of our products and would you like to see it in action?

We provide free R&D system demonstrations live online via video conference wherever you are in the world.

Scott Humphries or Steve Mate will demonstrate and explain advanced equipment features and allow you to see the processes that are relevant to your work. It will be an ideal time to discuss any challenges you...