This range of Variable Density extruders is designed to allow scale up starting from the initial development with the product saving, time saving and flexible Caleva Multi Lab (CML). Moving forward to the manufacture of larger trial batches (kilos rather than grams) the bench top VDE™ would be the preferred equipment.

You can be confident moving from the VDE to the production VD-TSE as the die hole configuration can be also accurately replicated in the production machine.

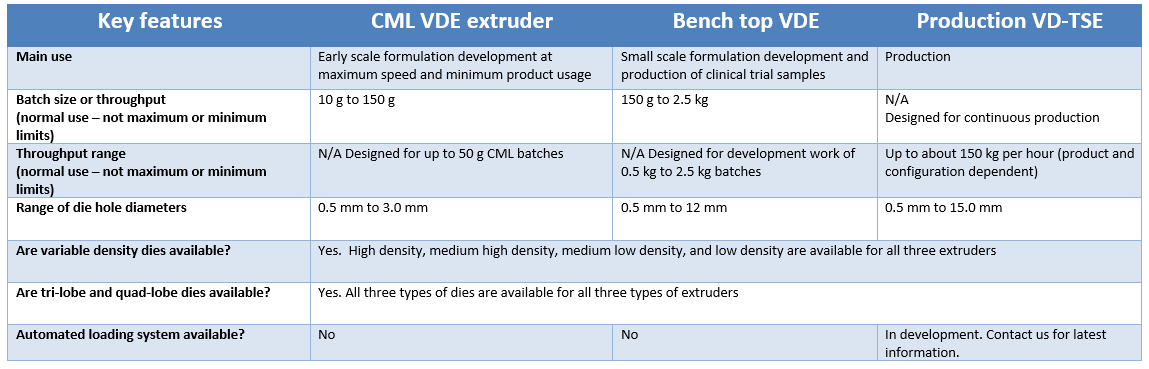

Caleva has a suite of three screw driven variable density extruders suitable for different uses, products and batch sizes.

- The Caleva Multi Lab extruder attachment (CML extruder attachment)

- The Caleva bench top Variable Density Extruder (VDE)

- The Caleva Variable Density Twin Screw Extruder (VD-TSE)

A Comparison of the Key Characteristics of three Caleva Variable Density machines

The optimum die configuration determined with the CML can be replicated with the larger bench-top VDE. Completing further trials with the same die configuration can give confidence that the parameters developed in the smaller machines can be replicated with larger batch sizes using the larger machines.

The key element in the extrusion process is the design parameters of the die holes and this is replicated through the complete range of Caleva Variable Density Extruders ensuring that scale up can be effectively managed through the whole development process.

Leave A Comment