Systematic development trials to establish optimum pellet formulations for pharmaceutical, nutraceutical or other related ingredients can require a significant time commitment. In modern industries pressure to generate results quickly has become the norm. Standard operating procedures generally follow a planned series of trials changing a single factor with each repetition. Not only is this the most sensible and efficient approach and is universally commonly used, but years of experience has shown that it is also the structure most likely to lead to optimum results.

This logical progression, changing one factor at a time, can lead to a large number of trials, examining not only the individual factors, but also how they interact with each other. Development programs can become a time consuming commitment and any factors that can be used to reduce the time required can be advantageous. If the number of individual trials completed per day can be increased then significant savings and productivity improvements can achieved.

You can view the full length video at the end of this page.

The Study

Recent trials completed in our laboratories have examined the time taken to complete the processes that make up a single individual trial with a simple pellet formulation. The time required to complete the different processes within a trial were recorded to allow examination on the effect on productivity of each step when using different laboratory systems. Three separate bench top systems were used for the trials. The results and some conclusions are shown below.

Methods and results

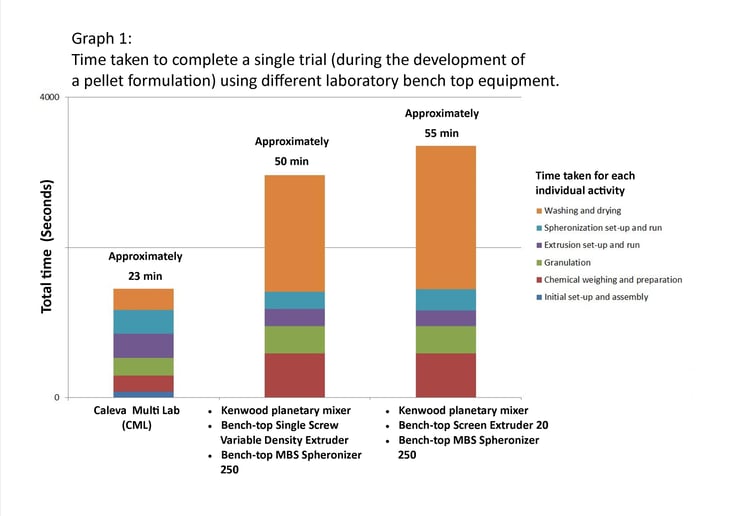

The results are shown on the graph below. The unique Caleva 3 in 1 laboratory bench top Multi Lab (CML) system was compared with two larger sets of different bench top equipment being individual bench top machines. These machines are representative of good and well-designed available bench top equipment. One set included a screen extruder and the other a screw-driven extruder. The time taken for each phase of the different experiments was recorded and consolidated. Some key points were noted during the trials.

- Initial set up time for the CML is longer than the set up time for the larger individual equipment. This is due to the attachments of the CML being small enough to be stored in a cupboard when not in use (and advantage). The stand-alone equipment remains on the bench-top whether in use or not. When in use the CML uses only about one third of the bench top space required by the stand-alone machines. The base unit for use with all three attachments has a “footprint” about the size of an A3 sheet of paper.

- The weighing and preparation of the sample size was quicker and easier with the CML. The smaller product quantities required are easier and quicker to obtain, to handle, and to weigh accurately. Working with smaller samples saves time as well as product cost. Batch sizes were 46.5 g with the Caleva CML and 620 g with each of the other systems. The product formulation was identical in all three trials

- The high shear mixer/granulator of the CML is faster than the Kenwood planetary mixer available to us for use with the other equipment. Less time is needed for this process in the high shear CML mixer. In the CML 4 minutes was used and with the planetary mixer 6 minutes was used. Confirmation of the rheological equivalence of the three different samples was not made.

- The smaller sample size used in the CML requires less material to be extruded. However the larger extruders have a faster throughput when compared to the small extruder in the CML. There were no benefits gained in this part.

- Spheronization time used is the same for all pieces of equipment (4 minutes).

- The smaller and more easily managed parts of the CML are significantly easier and faster to wash and dry than the larger and more difficult to handle parts of the larger equipment. Time taken to clean the extrusion screen from the Extruder 20 as well as the bowl from the larger MBS 250 spheronizer are the two most time consuming processes with the standard equipment.

- It was the characteristic of faster and easier cleaning that had the largest impact on improving trial efficiencies.

Conclusions

- The results of this investigation clearly demonstrate that working with the Caleva Multi lab (with a consistent batch size of up to 50 gram) instead of individual bench top components with batch sizes of about 500 g to about 1.5 kg can improve the number of trial repetitions that can be completed in a single laboratory session by more than 100%.

- The impact of this on the efficiency of completing trial iterations is remarkable. If we compare the 23 minutes required to complete a trial with the CML with the 50 and 55 minutes required for the other systems tested it shows that in a six hour laboratory session more than 12 CML repetitions should be possible and with the other standard bench-top equipment a maximum of about 6 trials could be completed!

- If cleaning time can be significantly reduced, as clearly demonstrated in this case, then this can provide dramatic improvement in development efficiency and general productivity of development work.

- The Caleva CML is designed to provide the opportunity to be washed and dried faster than any separate granulator, extruder and spheronizer based system available on the market. The achievable benefit of the CML is clearly demonstrated.

Leave A Comment