Did you know that the Mixer Torque Rheometer (MTR) is designed to carry out 3 separate experiments essential to your formulation development and production?

As well as providing you with quantitative rheological measurements to aid in your formulation development, it can also be used to check quality in a pilot scale or commercial production line to save both time and money.

Here we look at the three key experiments available with the MTR, examining why they are used and how they can support your formulation development and production.

Multiple Addition Experiment

To establish the ideal ratio of powder to liquid for solid dose formulations, extrusion or spheronization.

How is it done?

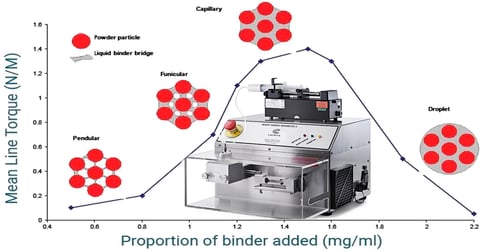

The Multiple Addition test mixes dry powders, then adds between 0.5 and 3ml of liquid binder at a time as designated by the user, mixing, and measuring torque at 200 data points per second. This process continues until the material turns into a slurry.

The MTR then creates a graph and table of the torque created by the mixing – typically a bell curve showing first an increase and then a decrease in torque as the material turns into a slurry.

As the torque increases you can identify the ideal ratio of powder to liquid for either solid dose tablet formulations, or for extrusion and spheronization.

Variable Mix Time Experiment

To identify the optimum mixing time for homogeneity

How is it done?

Once you have used the Multiple Addition test to establish the ideal powder to liquid ratio, you can then use this formulation to conduct the Variable Mix Time experiment.

For this, the machine adds the specified amount of binder in one dose at the beginning, then mixes for a given number of minutes. This then creates a graph and table of the torque reading as the torque increases, as the mixture becomes more homogenous.

The peak of the torque reading is the ideal mix time for your formulation.

Consistency Test

To monitor the consistency of product within your production line to identify and resolve issues quickly.

How is it done?

Using the Mixer Torque rheometer, you can take a sample of the granulation from a production line and test it at regular intervals to ensure consistency.

By comparing the torque readings over a batch/shift you can quickly identify and resolve issues to minimise disruption to your production.

Through regular testing you can quickly identify issues within your production line and resolve them quickly to save both time and money.

Summary

Regardless of the complexity of your formula, the Multiple Addition experiment and Variable Mix Time experiment provide you with reproducible data for different binders and mixing times to save you both time and money in your formulation development.

Using the Caleva Mixer Torque Rheometer you can optimise your formulations in the shortest possible time, enabling you to investigate product and excipient quality issues in a quantitative and meaningful way.

The vital data it provides can be used as part of your scale-up or even for precise quality control in production.

You can find out more about the MTR in our video below or contact the team today

Leave A Comment