Replace the subjective 'hand squeeze' or 'snowball' test with precision data provided by the Mixer Torque Rheometer (MTR). Remove the guesswork and let the MTR accelerate and enhance your research and development experiments and maintain quality and protect yields in your production line.

Designed to measure and characterise wet granulation properties for tabletting, extrusion, and spheronization outcomes, the MTR helps you to reduce material waste, save time, save money and increase your Return-On-Investment throughout the product lifecycle.

*Suitable for use with gloves

The new MTR builds on many years of experience in providing highly accurate data for groundbreaking studies across multiple industries. Designed to optimise liquid-to-powder ratios, provide indications of granule strength and reduce material waste, the MTR can define a robust design space to speed up your formulation development, support scale up, and ensure quality and yields are maintained in production environments.

Using just 15-40g samples, the Mixer Torque Rheometer (MTR) provides exhaustive and accurate data about your granulation by precisely measuring the torque generated during the mixing process. 200 data points are recorded every second to give extremely precise results. The resulting data allows you to predict and optimise liquid-to-powder ratio and the robustness of your formulation.

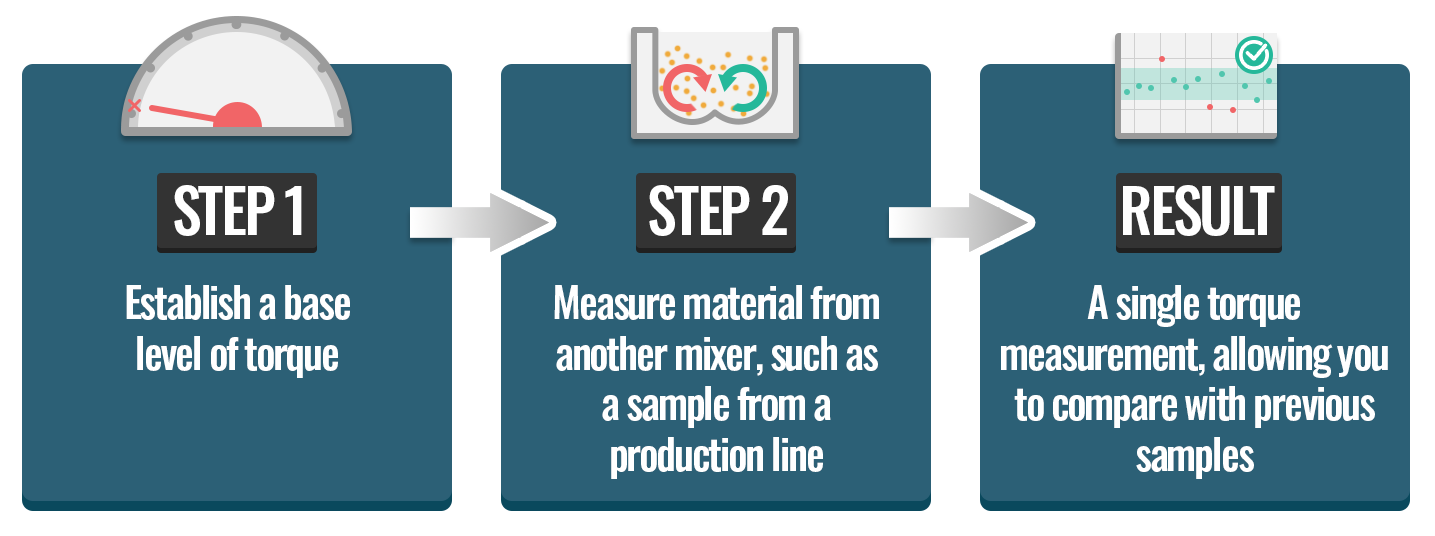

The MTR also provides a quick quantitative method for benchmark and comparison during scale-up or production.

With an intuitive user interface and full control over process parameters you can make more informed decisions faster with quantitative data displayed as it happens. Alternatively you can export your data for further investigation and deeper insights.

The Mixer Torque Rheometer performs three experiments that help to optimise your wet granulation by providing precise, repeatable data.

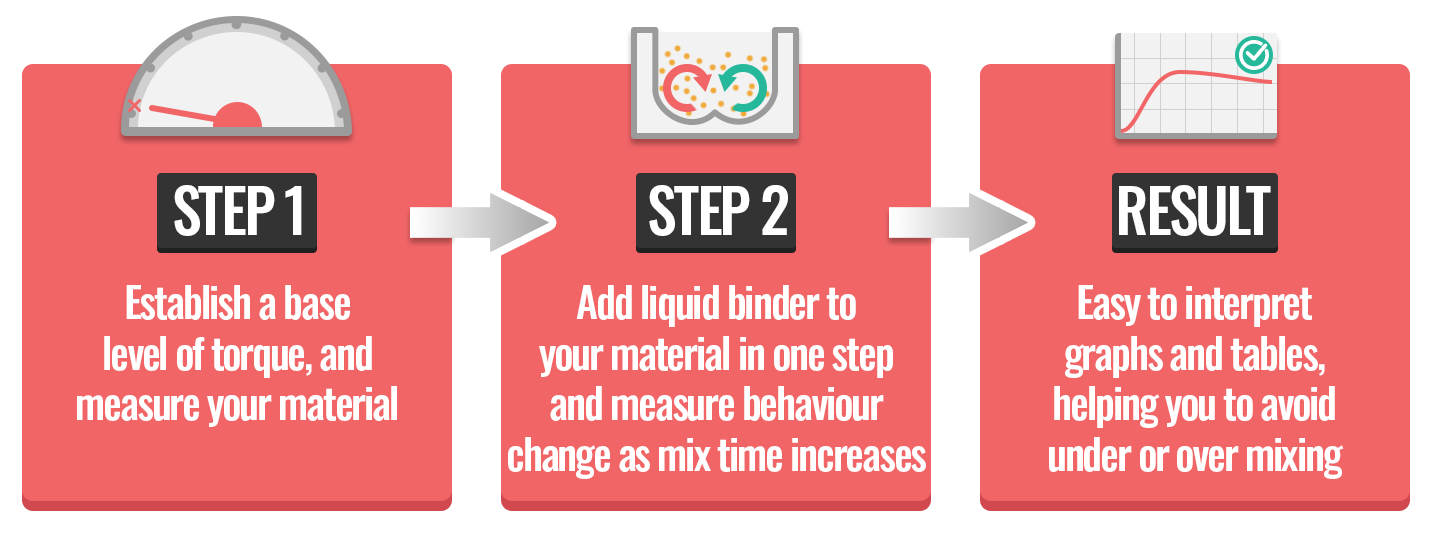

Reduce material waste and speed up formulation development. Remove the guesswork from your experiments and predict the optimal binder-to-powder ratio for your wet granulation.

Prevent under or over mixing. Identify the influence of mixing duration to provide an understanding of the robustness of the formulation.

Maintain product quality and usable yield. Monitor your wet granulation’s consistency as part of a scale-up strategy or during production to enable quick corrections.

Skip the lengthy trial and error stage of establishing liquid to solid ratios and optimal mix time to support reliable die filling, reduced segregation, and stronger tablet formation. The MTR is a vital companion for speeding up formulation development for tablets - especially when the active pharmaceutical ingredient (API) is expensive or in short supply.

Replace the subjective 'hand squeeze test' and quickly identify the optimal amount of liquid binder to powder ratio, and mix time needed to define your design space for successful extrusion and spheronization outcomes.

Ensure a seamless transition from laboratory-scale experiments up to pilot, batch or continuous production. The MTR can help you achieve consistent results as you scale, eliminating concerns about material differences between lab and production scale equipment and performance across different brands.

Use the MTR to establish and maintain rigorous quality control standards, leading to enhanced product quality and usable yield. As a line side tool, the MTR can help you ensure product consistency across different operators, different lines or batches and even different production sites. Identify issues quickly to avoid costly downtime and wasted batches.

Researchers and manufacturers can use the detailed insights provided by the MTR to optimise their powder formulations, leading to improved process efficiencies and a deeper understanding of powder behaviour during processing, to achieve high-quality products.

We express our sincere appreciation to Caleva for providing us with the essential Mixer Torque Rheometer (MTR), a critical component in our wet granulation formulation studies at Nobel İlaç. The support and equipment supplied by Caleva have been instrumental in our research endeavors. We appreciate the opportunities this technology has presented, allowing us to conduct in-depth analyses of our formulations for tablets, extrudate, and pellets. We excite about the prospects of advancing our research with the MTR. Thank you for your support and we are eager to further explore the possibilities ahead.

Sinem Yetim Pharmaceutical R&D Specialist and Mentor at Nobel İlaç, Türkiye

Using the CML and MTR in combination we’re learning a lot about our catalyst material. The machines are easy to use, and we have achieved very accurate measurements, giving us precise repeatability. The MTR has been a massive advantage in our research and we’re doing things with the material we didn’t think were possible. The speed and ease of use have allowed us to conduct numerous experiments in a single day - we’ve accumulated vast amounts of data to inform our scale up. Both the CML and MTR are manufactured to a very high standard and are very dependable.

IGTL Technology LTD

I have found using Caleva’s Mixer Torque Rheometer (MTR) and the Multi-Lab (granulator, extruder and spheronizer) most valuable in my research where I am reformulating existing active pharmaceutical ingredients into smarter formulations capable of minimising the associated pill burden among patients taking multiple medication as well as improving access to essential medicines.

Dr Francis Brako The Medway School of Pharmacy

Read articles and real-life case studies featuring the MTR to find out how it can benefit your work

Precise quantitative data about your wet granulation provided by the MTR helps to accelerate and enhance your research, development and production projects, reducing material, time and costs.

To ensure the most accurate data is provided for your project, the Caleva MTR measures torque at the blade's edge where your formulation is in contact with the machine. This precise data gives you peace of mind about making the correct decision for your next stage.

Using the MTR allows you to accurately ensure your formulation can be scaled up and achieve a return on investment. Ensure you only use the energy, time and resources you need for your optimum formulation.

The single safety guard, hinged for convenience, is fitted with a high-integrity safety device preventing the machine from operating until the guard is properly in place. A simple, quick release mechanism allows the guard to be easily removed for cleaning.

Ease of use is central to the MTR design, with all attachments being quick and simple to attach and remove. Locator pins and clever design minimise the potential for accidental misuse or equipment damage.

Reliable and repeatable results are essential to validate your studies and ensure accurate scale-up programmes. Regular, proactive maintenance and the immediate replacement of worn parts is key to this and ensure compliance with GLP requirements.

Essential and Consumable spares kits are available for all Caleva equipment to keep your research on target and your results scalable.

Please call us without obligation.

+44 (0) 1258 471122Please call us without obligation.

+44 (0) 1258 471122